Autotrophic nitrogen removal device adopting low-carbon-source urban sewage step-feed multi-stage A/O (Anoxic-Oxic) process based on short-cut denitrification and application method

A technology for short-range denitrification and urban sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

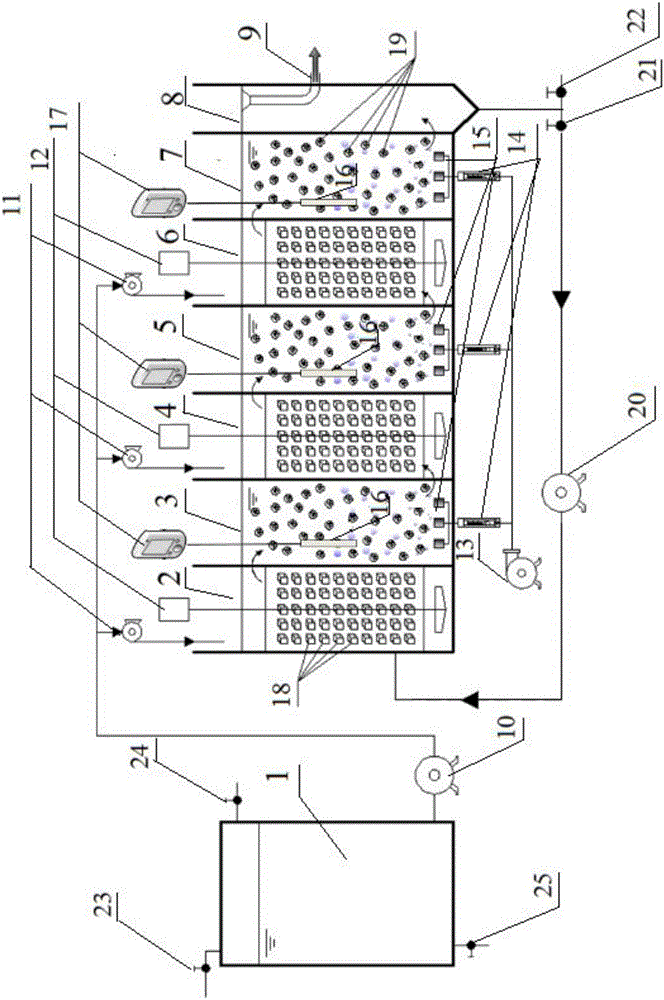

[0025] Specific Embodiment 1: This embodiment is an autotrophic denitrification device based on short-range denitrification of low-carbon source urban sewage segmented water intake multi-stage A / O process, which is characterized in that the device includes urban sewage raw water tank 1 and segmented water intake multi-stage A / O device;

[0026] The upper end of the urban sewage raw water tank 1 is provided with a water inlet pipe 23 and an overflow pipe 24, and the lower end is provided with an emptying pipe 25; the multi-stage A / O device for segmented water inlet is divided into seven zones by a perforated partition, Along the direction of water inflow are the first anoxic reaction zone 2, the first contact oxidation zone 3, the second anoxic reaction zone 4, the second contact oxidation zone 5, the third anoxic reaction zone 6, and the second anoxic reaction zone. The three-section contact oxidation zone 7 and the precipitation zone 8; the urban sewage raw water tank 1 adop...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment is different from Embodiment 1 in that: the sponge 18 is fixed on the packing frame, and the filling ratio is 30-50%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0031] Specific implementation method three: the application method of the autotrophic denitrification device based on the short-range denitrification-based low-carbon source urban sewage segmented multi-stage A / O process, according to the following steps:

[0032] 1. Inoculation initiation phase

[0033] The first-stage contact oxidation reaction zone 3, the second-stage contact oxidation reaction zone 5 and the third-stage contact oxidation reaction zone 7 are all inoculated with polypropylene hollow ring 19 fillers with nitrifying properties and mature film formation, and the filling ratio reaches 40-60. %; Start water pump 10 to inject municipal sewage in the reactor, then start air compressor 13 and open the air rotor flowmeter, contact oxidation reaction zone 3 for the first section, contact oxidation reaction zone 5 for the second section and contact the third section The oxidation reaction zone 7 is aerated to maintain the dissolved oxygen concentration DO = 3 ~ 5mg / L,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com