A kind of preparation method and product of vitamin C-coated copper-zinc-tin-sulfur nanoparticles

A copper-zinc-tin-sulfur and nanoparticle technology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as unfavorable industrial production, and achieve non-toxicity, good application prospects, and reaction The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

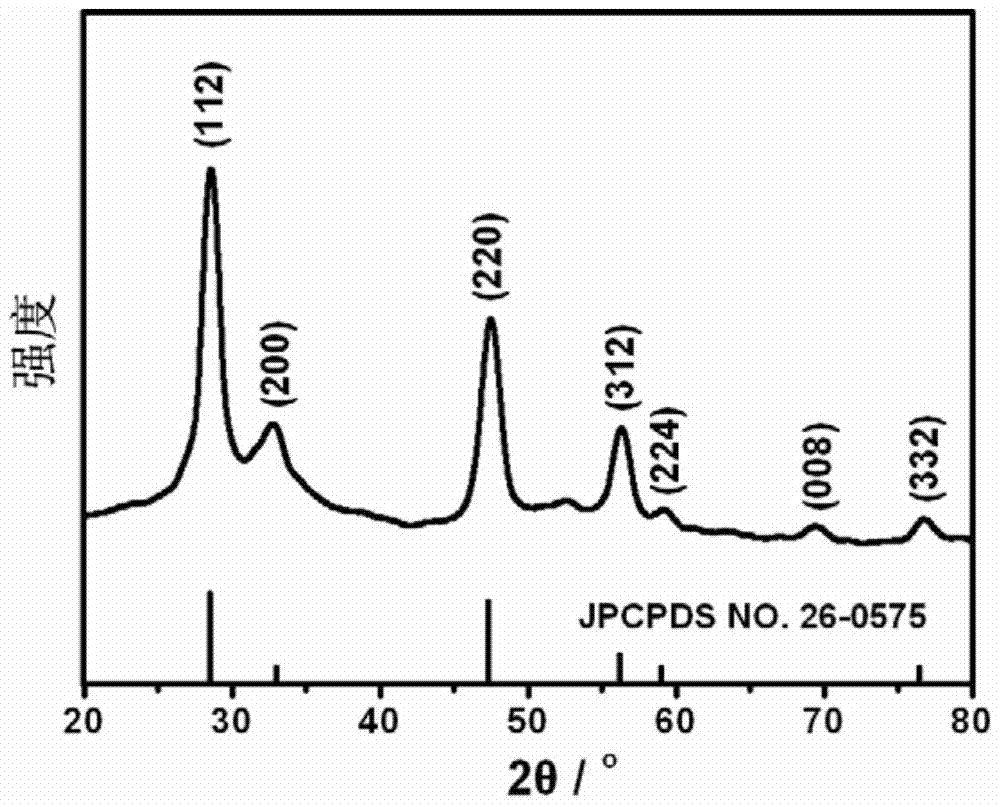

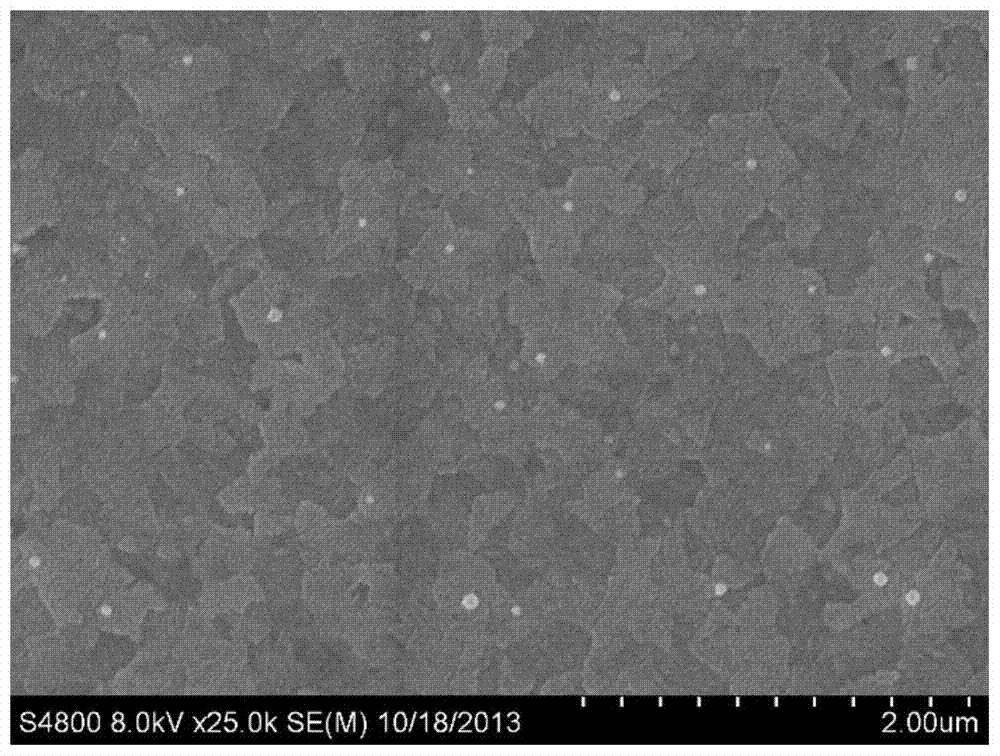

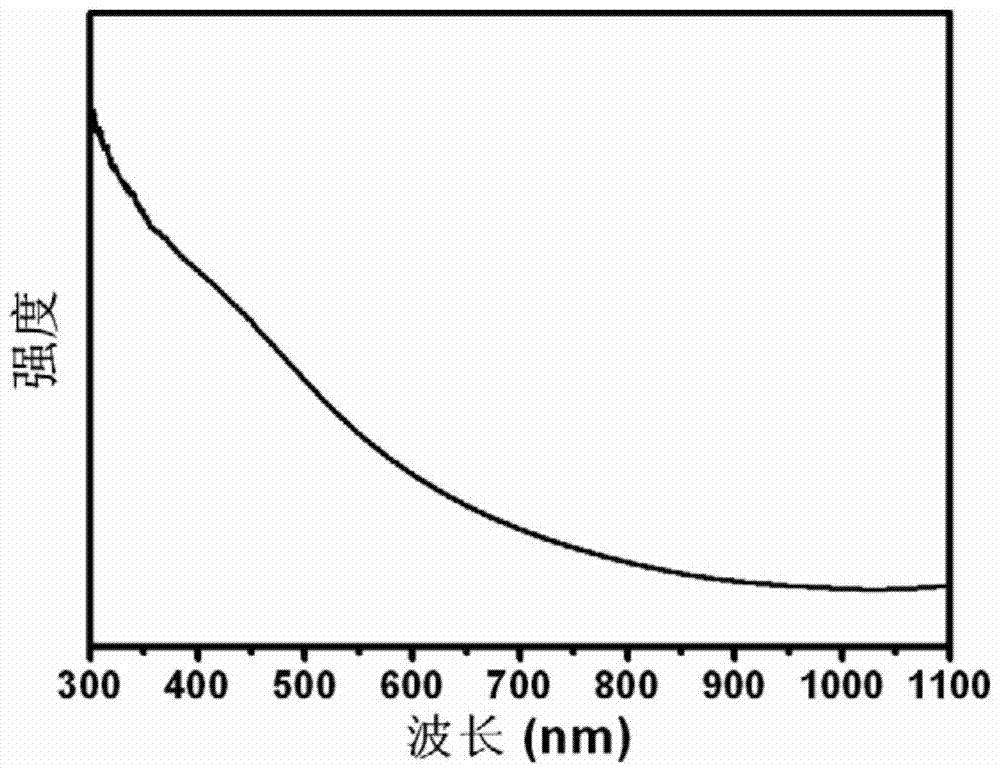

[0034] Dissolve 1.25mmol copper acetate, 0.625mmol zinc chloride, 0.625mmol tin chloride and 1.25mmol vitamin C in 40mL DMSO solvent, heat up to 155°C; at the same time, dissolve 2.5mmol sodium sulfide in a mixture of 5mL ethanol and 50mL DMSO in the solvent; then, drop the sodium sulfide solution into the metal source solution for 10 minutes; maintain the reaction temperature at 150°C for 6 hours. The CuZnSnS nanoparticles were sedimented with acetone and centrifuged to obtain a black solid. Add 30mL of water, sonicate for 10min, then add 30mL of acetone, and centrifuge to obtain pure vitamin C-coated copper-zinc-tin-sulfur nanoparticles. Its XRD pattern is as follows figure 1 shown. The synthesized copper-zinc-tin-sulfur nanoparticles are in the crystal form of copper-zinc-tin-zinc ore, which is consistent with the XRD standard card JCPDS No.26-0575. figure 2 The scanning electron microscope image of the vitamin C-wrapped copper-zinc-tin-sulfur nanoparticles prepared for...

Embodiment 2

[0036]Dissolve 1.25mmol copper acetate, 0.625mmol zinc chloride, 0.625mmol tin chloride and 1.25mmol vitamin C in 40mL DMSO, heat up to 155°C; at the same time, dissolve 2.5mmol sodium sulfide in a mixed solvent of 5mL water and 50mL DMSO Then, drop the sodium sulfide solution into the metal source solution for 10 minutes; maintain the reaction temperature at 150°C for 1 hour. The CuZnSnS nanoparticles were sedimented with acetone and centrifuged to obtain a black solid. Add 30mL of water, sonicate for 10min, then add 30mL of acetone, and centrifuge to obtain pure vitamin C-coated copper-zinc-tin-sulfur nanoparticles.

Embodiment 3

[0038] Dissolve 1.25mmol copper acetate, 0.625mmol zinc chloride, 0.625mmol tin chloride and 1.25mmol vitamin C in 40mL DMSO, heat up to 155°C; at the same time, dissolve 2.5mmol sodium sulfide in a mixed solvent of 5mL methanol and 50mL DMSO Then, drop the sodium sulfide solution into the metal source solution for 10 minutes; maintain the reaction temperature at 150°C for 6 hours. The CuZnSnS nanoparticles were sedimented with acetone and centrifuged to obtain a black solid. Add 30mL of water, sonicate for 10min, then add 30mL of acetone, and centrifuge to obtain pure vitamin C-coated copper-zinc-tin-sulfur nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com