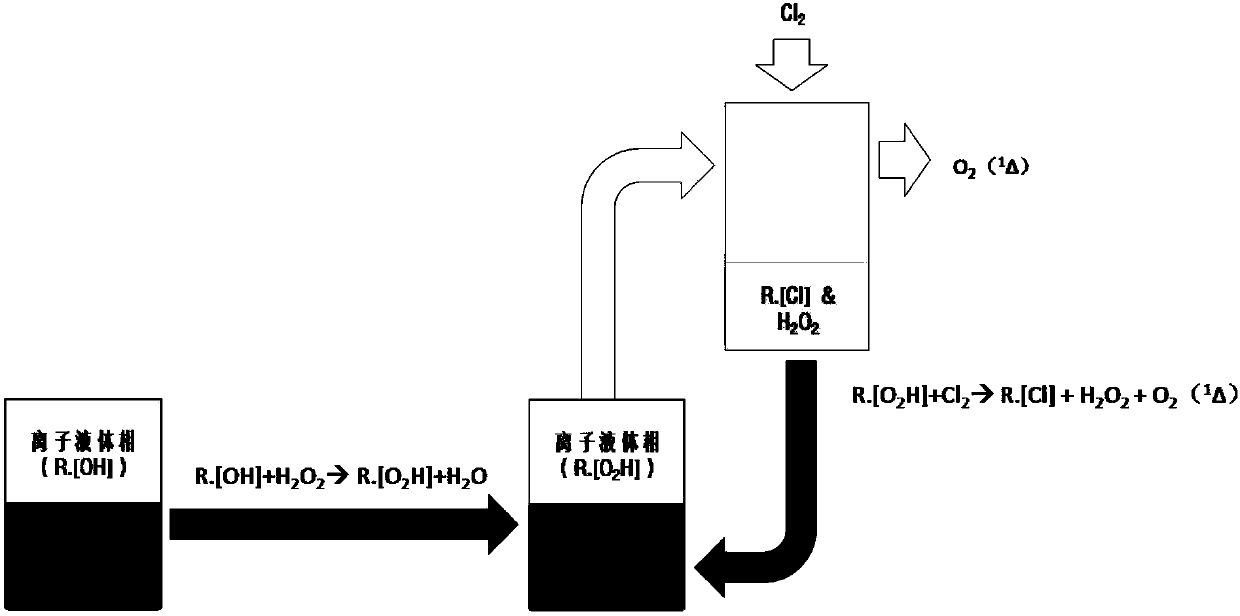

A method for generating singlet oxygen based on a two-phase transfer system

A singlet oxygen generation method technology, applied to laser components, electrical components, lasers, etc., can solve the problems of unacceptable operating costs of oxygen-iodine chemical lasers, increase operating costs of oxygen-iodine chemical lasers, and high extraction costs. The effect of strong combination ability, high usage efficiency and loose constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1 kg of alkaline ionic liquid C 3 f 7 wxya 3 .[OH], 1 kilogram of concentration is that the aqueous hydrogen peroxide solution of 5mol / L is placed in the raw material storage tank and mixed and stirred, at this moment C 3 f 7 wxya 3 .[OH] absorbs hydrogen peroxide from aqueous hydrogen peroxide phase, C 3 f 7 wxya 3 .[OH] reacts with hydrogen peroxide to generate C 3 f 7 wxya 3 .[O 2 H], finally forming a C 3 f 7 wxya 3 .[O 2 A two-phase system in which the ionic liquid phase of H] and the hydrogen peroxide aqueous solution coexist; the ionic liquid phase is extracted into a small jet-type singlet oxygen generator to react with chlorine gas, and the singlet oxygen can be obtained at the outlet of the generator. The other two products obtained hydrogen peroxide, C 3 f 7 wxya 3 .[Cl] and unreacted C 3 f 7 wxya 3 .[O 2 H] return in the raw material storage tank, hydrogen peroxide will automatically enter the aqueous hydrogen peroxide phase, and C 3 f ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com