Discharged material sorting and positioning device for production line of wood-plastic composite (HPC) boards

A positioning device and production line technology, applied in classification, solid separation, transportation and packaging, etc., can solve the problems of low automation, high labor intensity and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

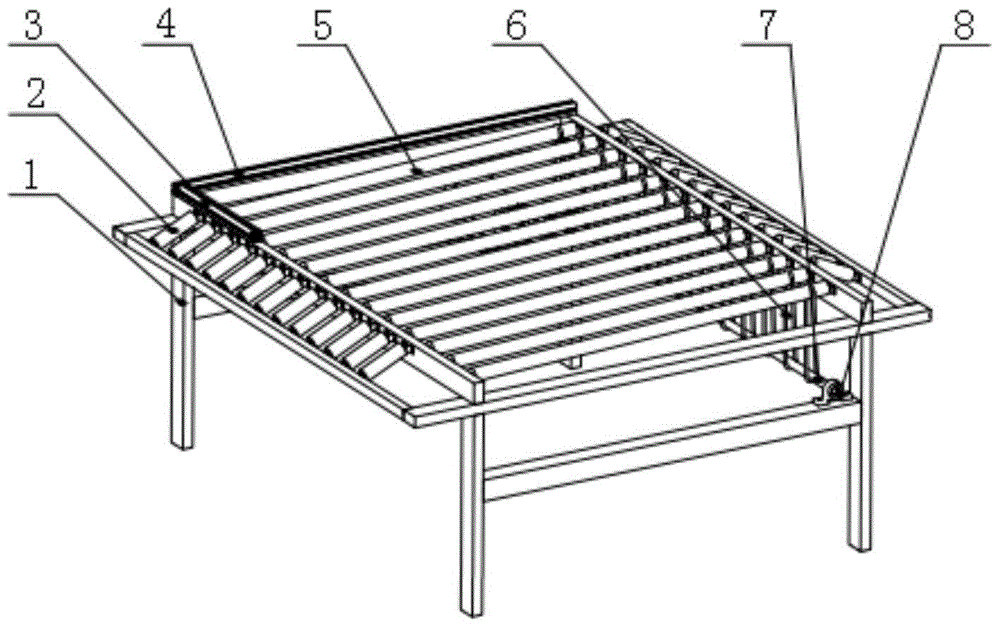

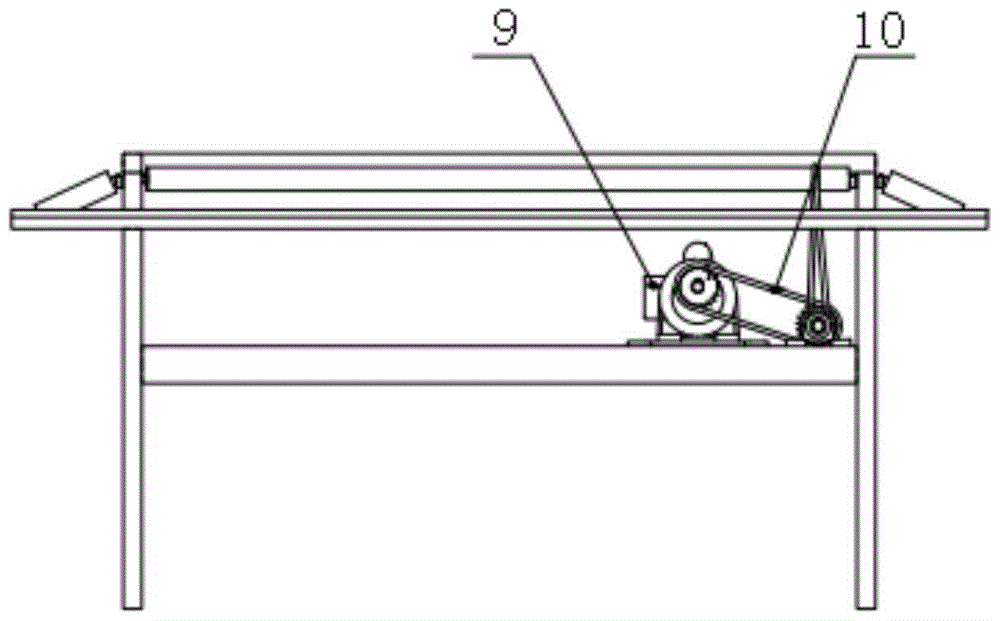

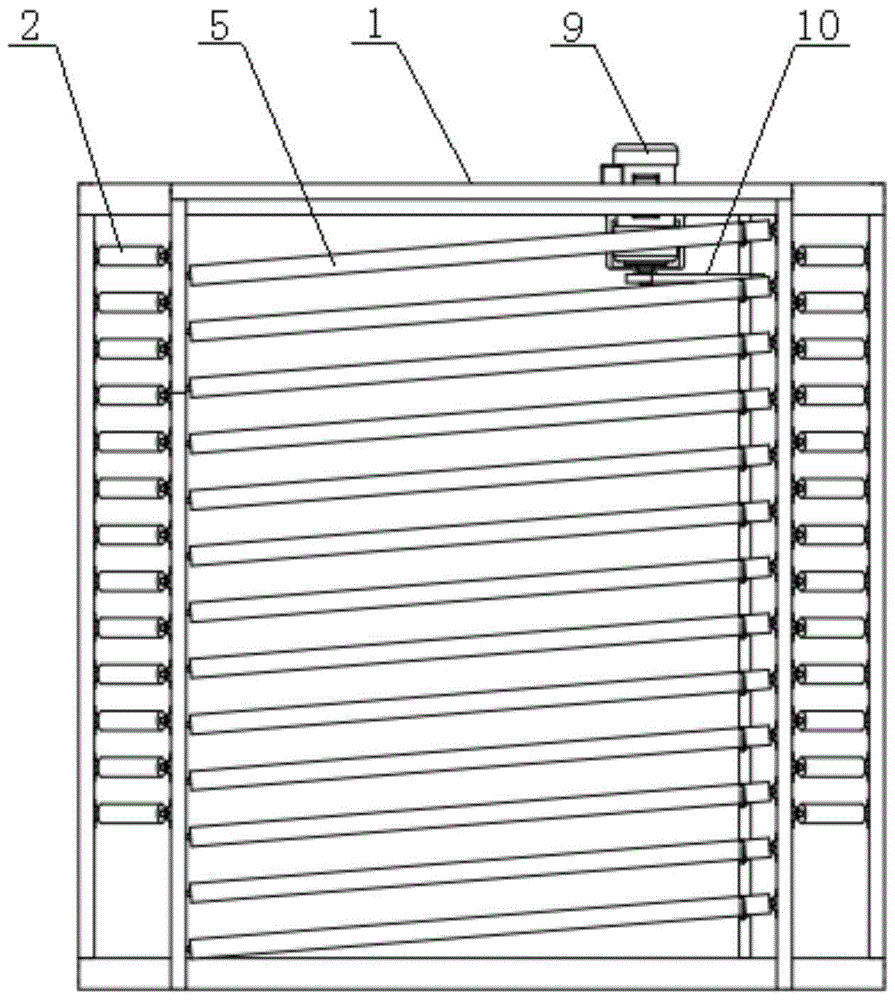

[0026] Such as figure 1 , figure 2 with image 3 As shown, the discharge sorting and positioning device for a wood-plastic substrate (HPC board) production line of this embodiment includes a main frame 1, several central idlers 5 and power components, and several central idlers 5 are parallel to each other and parallel to each other. They are respectively rotatably connected to the main frame 1, and several side rollers 2 are arranged on both sides of several central rollers 5 respectively. Specifically, in this embodiment, the lower part of the main frame 1 is a supporting leg assembly; as image 3 As shown, the upper part of the main frame 1 is arranged in parallel with the first bracket, the second bracket, the third bracket and the fourth bracket in turn from left to right, and several central rollers 5 of the present embodiment are connected to the second bracket and the third bracket between, and the angle between each central roller 5 and the second bracket is an ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com