Novel corrosion-resistant steel-plastic faceplate for composite water tank and manufacturing method of faceplate

A corrosion-resistant, steel-plastic technology, which is applied in the field of new corrosion-resistant steel-plastic panels for composite water tanks and the preparation field, can solve the problems of water leakage, chlorine ion corrosion and rust of water tanks, etc., so as to increase the service life and eliminate water sources Direct contact with steel plate, effect of anti-corrosion service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

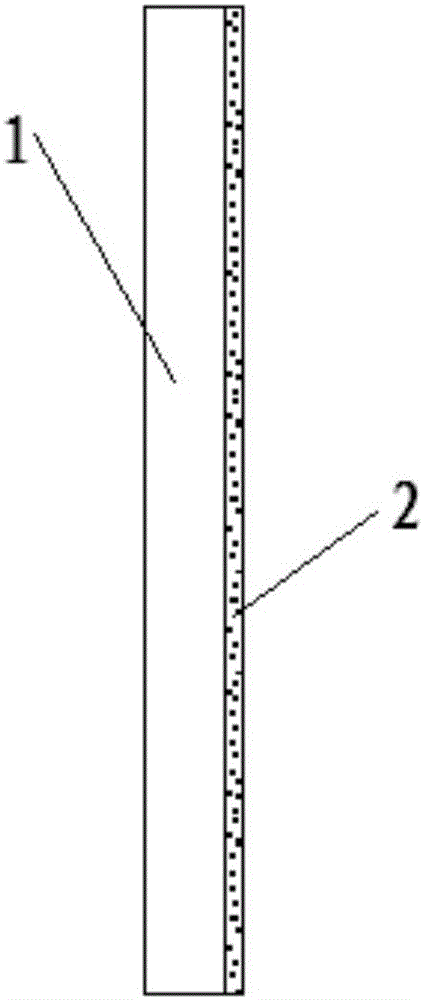

[0013] figure 1 As shown, a novel corrosion-resistant steel-plastic panel for a composite water tank is disclosed, which includes a molded board 1 , and a PE plastic layer 2 is provided on one side of the molded board 1 . Preferably, the thickness of the PE plastic layer 2 is 0.25-0.5 mm.

[0014] The preparation method of the steel-plastic panel for the above-mentioned composite water tank comprises the following steps:

[0015] First, cut the 304 stainless steel or Q235 steel plate into a flat plate, and then punch the flat plate into a molded plate of the required size through a gravity press 1;

[0016] Secondly, after the molded plate 1 is stamped, the surface of the molded plate 1 is sandblasted and roughened by a sandblasting process; wherein, the sandblasting thickness is 0.25-0.5mm, and the sandblasting grade is Sa2.5;

[0017] Finally, spray food-grade PE plastic powder on the surface of the sandblasted molding board 1, and then put it into a high-temperature oven ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com