press machine

A press and driving force technology, applied in the field of presses, can solve the problems of uncertain rotation direction of the driven crankshaft, high cost, complex structure, etc., and achieve the effects of improving start-stop performance, reducing manufacturing cost, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Hereinafter, in order to clarify the present invention more concretely, embodiments of the present invention will be described in detail with reference to the drawings.

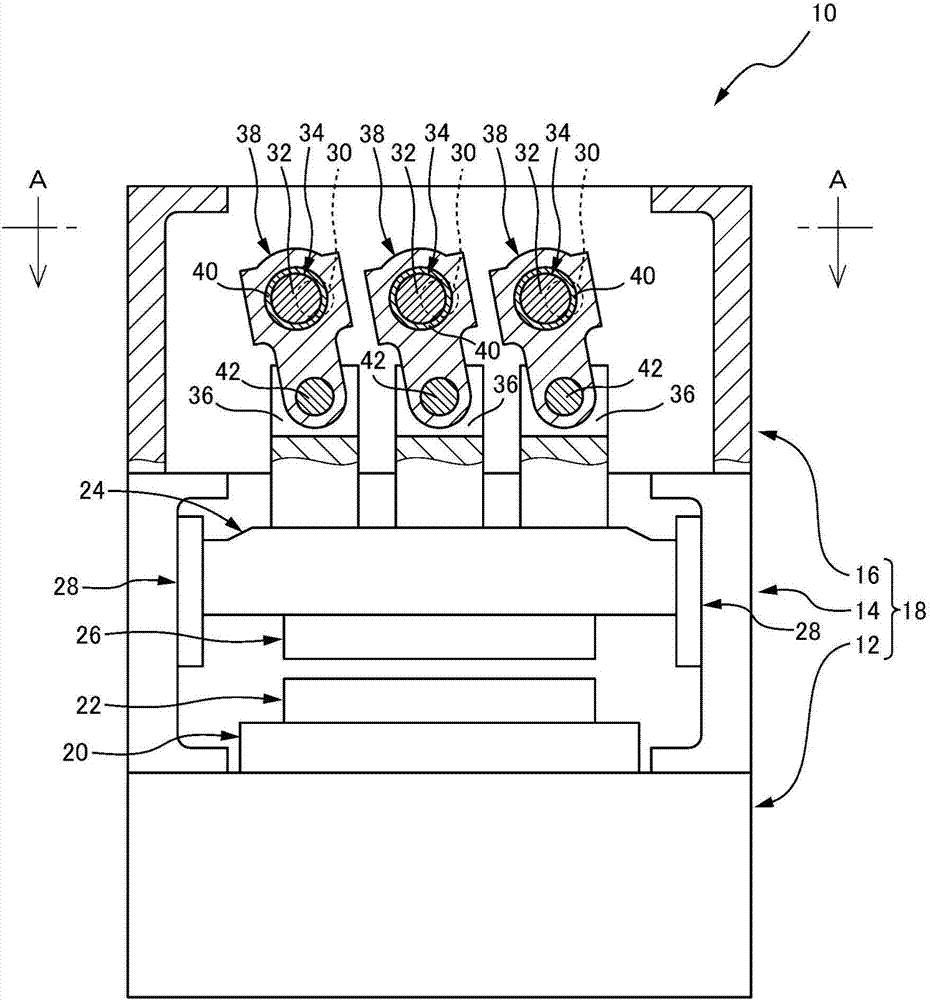

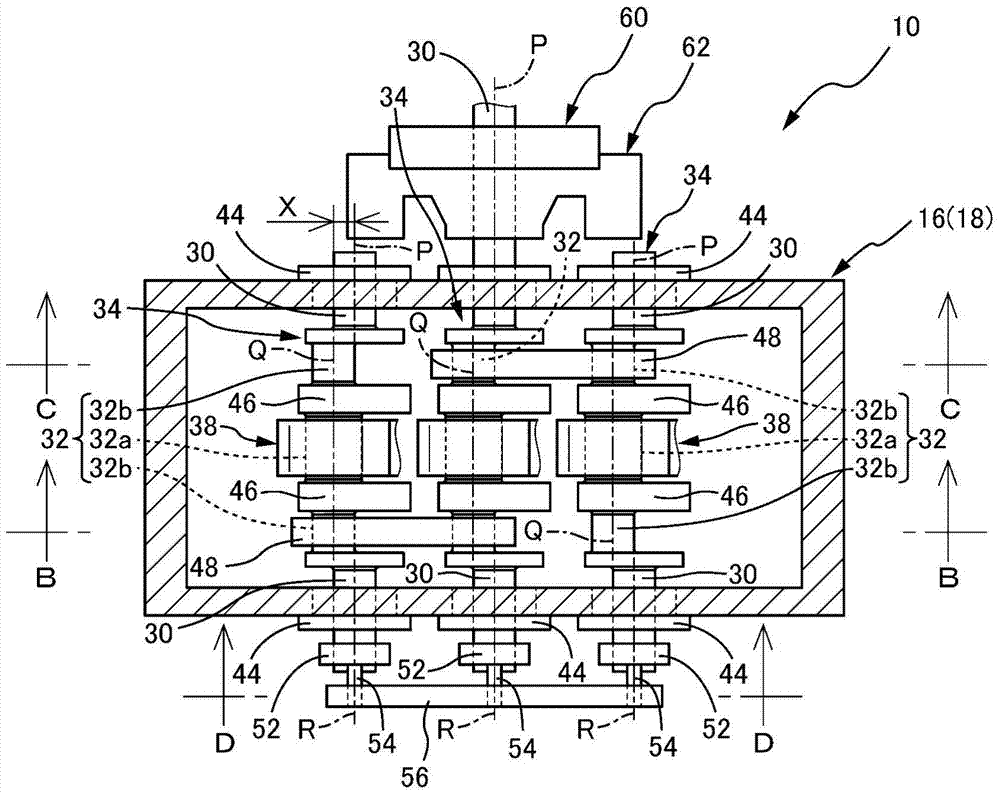

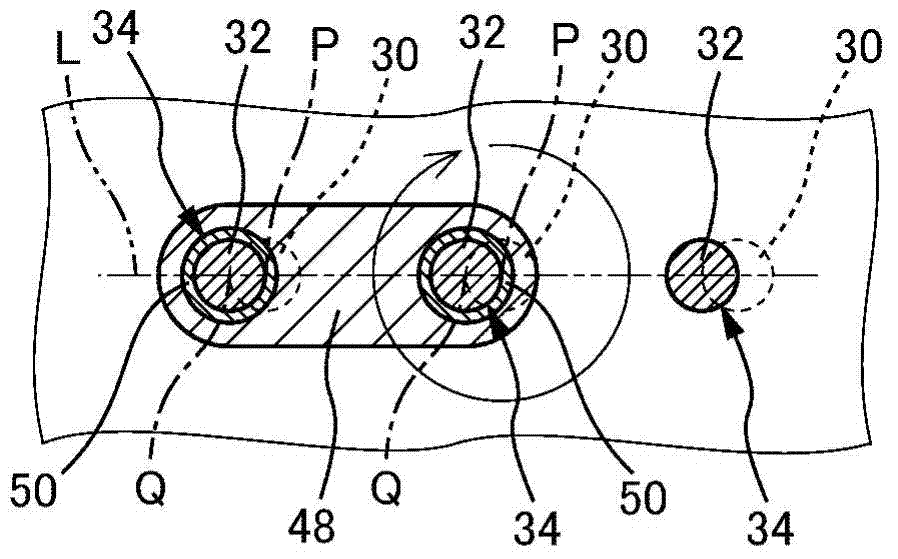

[0058] first, figure 1 An example of a press according to the present invention is shown in a front view including a part in section. Here, the press machine 10 is provided with a frame body 18 of an integral structure composed of a lower frame body 12 , an intermediate frame body 14 , and an upper frame body 16 . The lower die 22 is attached, and an upper die 26 constituting a press die together with the lower die 22 is attached to the lower surface of the slider 24 arranged in the intermediate frame 14 . In addition, the slider 24 is arranged in a vertically movable state guided by a pair of slider guides 28 , 28 provided to face the inner wall surface of the intermediate housing 14 . In addition, as will be described later, the upper housing 16 is rotatably supported by a plurality of (here, three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com