Optical lens die casting device

A technology of optical lenses and switching devices, which is applied to optical components, other household appliances, household appliances, etc., can solve the problems of long pressing station time, slow transfer speed, personal injury accidents, etc., and achieves shortened molding pressing time and high production efficiency The effect of improving and good optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

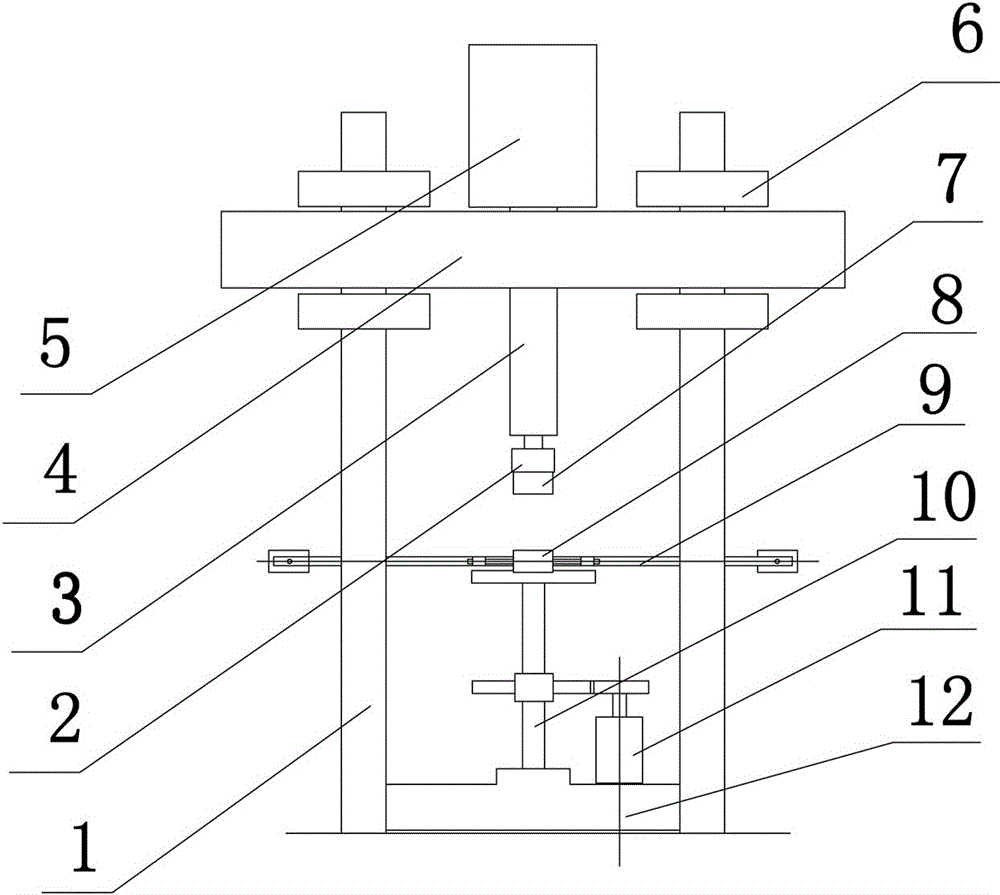

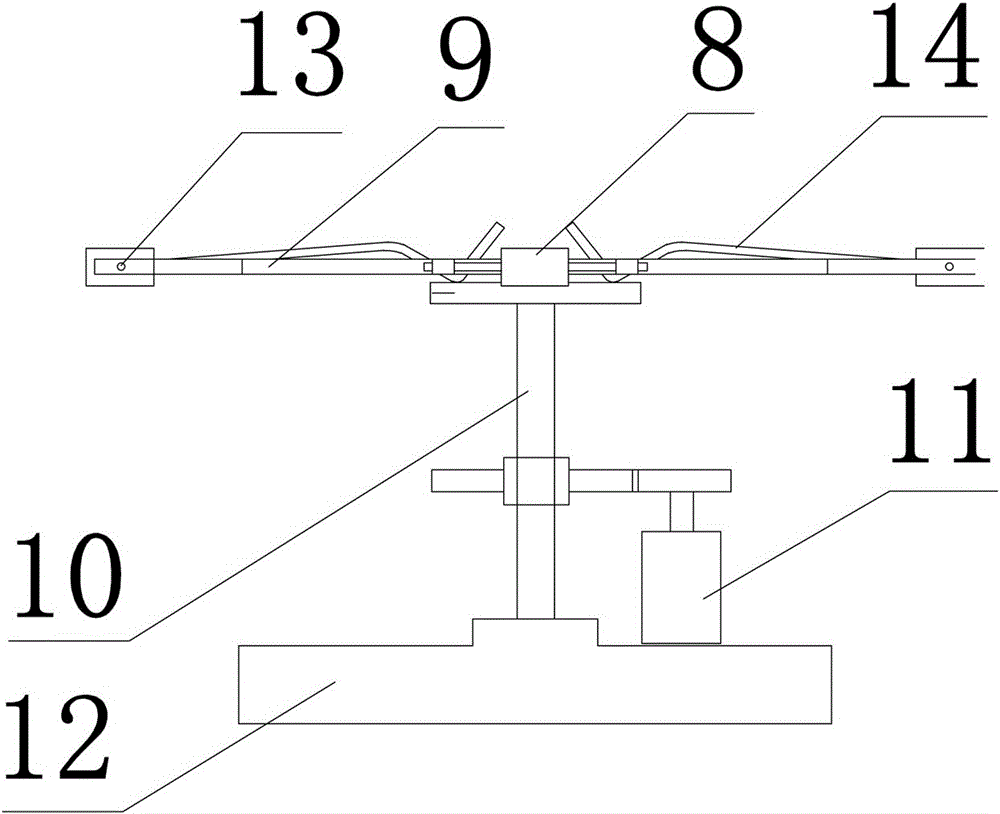

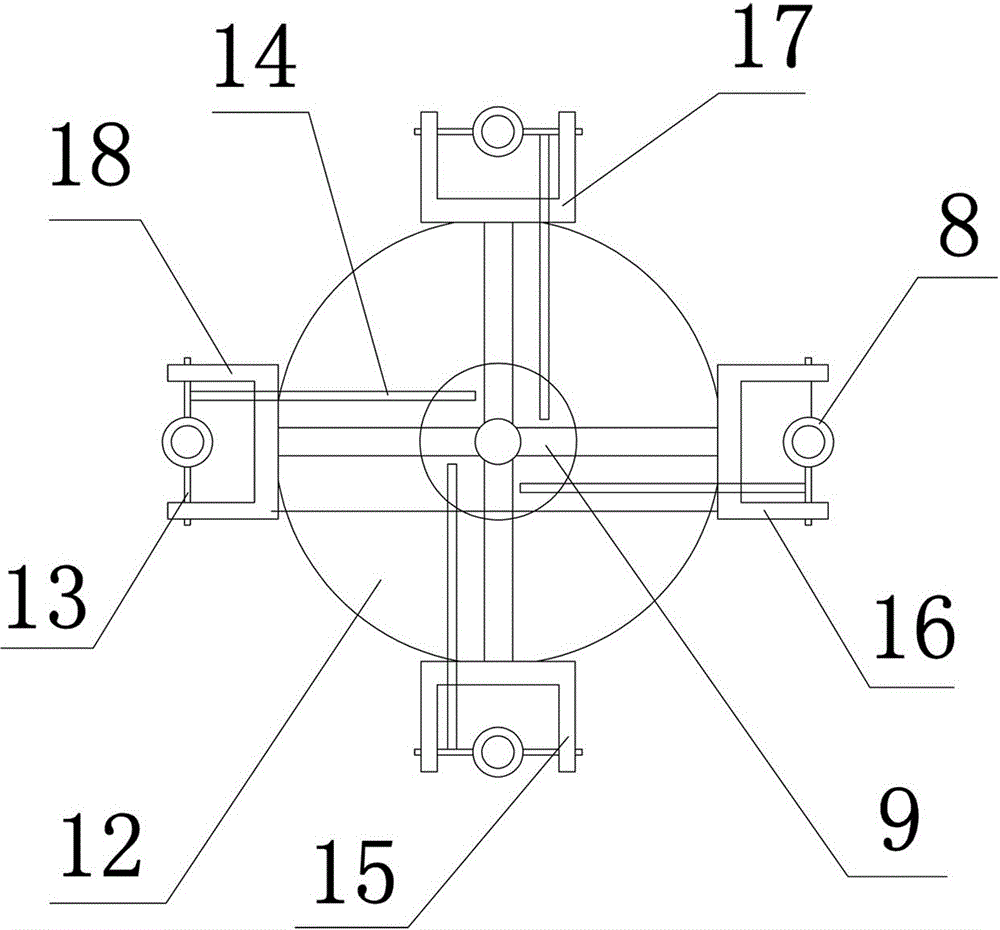

[0026] Such as figure 1 , figure 2 , image 3 As shown, the optical lens die-casting device of the present invention includes a press, a die-casting mold and a multi-station switching device. Wherein, the press machine includes a guide column 1, a beam 4 and a pressure head 2, a pressure hydraulic cylinder 5 is installed on the top of the beam 4, and the pressure head 2 is installed and connected with the piston rod 3 of the pressure fluid cylinder 5. The die-casting mold is composed of an upper die 7 and a plurality of lower dies 8, the upper die 7 is connected to the lower end of the press head 2, and the lower dies 8 are respectively installed on each station of the multi-station switching device. The multi-station switching device includes a base 12 and a mold bracket 9, the mold bracket 9 is connected to the base 12 through a central shaft 10 and a bearing, and the central shaft 10 is connected to a servo motor 11 through a transmission part to drive the central shaft ...

Embodiment 2

[0029] combine figure 2 , image 3 see Figure 4 , this embodiment is a further improvement on the basis of the technical solution of Embodiment 1. In order to further improve the quality of lens die-casting, prevent damage to the mold bracket 9 and prolong its service life, a mold support structure can be provided under the die-casting station 15, The mold support mechanism has a support 19, and a spacer 21 is arranged on the top of the support 19. The height of the top surface of the spacer 21 should be basically equal to the bottom end surface of the lower mold 8, so as to ensure that the lower mold 8 rotates with the mold bracket 9 freedom, and the gap should not be too large. Also can install a telescopic liquid cylinder 22 by connecting support plate 20 on bearing 19, its telescoping end is connected with spacer 21, and spacer 21 is delivered to the below of counterdie after counterdie 8 rotates in place again.

Embodiment 3

[0031] combine figure 2 , image 3 see Figure 5, as a further improvement, the optical lens die-casting device of the present embodiment is provided with a cutting mechanism on the side of the die-casting station 15, which includes upper and lower cutters 24, 25 corresponding to each other, and the upper and lower cutters 24, 25 are respectively connected with compressed fluid Cylinder I, II 23, 26. The cutting mechanism can also be set in combination with the mold support mechanism. The compression cylinder I 23 of the upper cutter 24 can be fixedly connected to the top of the support 19 in the mold support mechanism through the bracket 27, and the compression cylinder II 26 of the lower cutter 25 can be installed on the mold support mechanism. The bottom of the support 19 platens. The positions of the upper and lower cutters 24 and 25 should be as close as possible to the die-casting mold, so as to save the raw material consumption of the lens and reduce the workload of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com