Laser pretreatment device and method with transparent optical elements arranged side by side

A technology of laser pretreatment and optical components, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of inapplicable laser pretreatment and long time consumption, achieve high-efficiency laser damage threshold, and compress the pretreatment time period , Improve the effect of laser damage threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

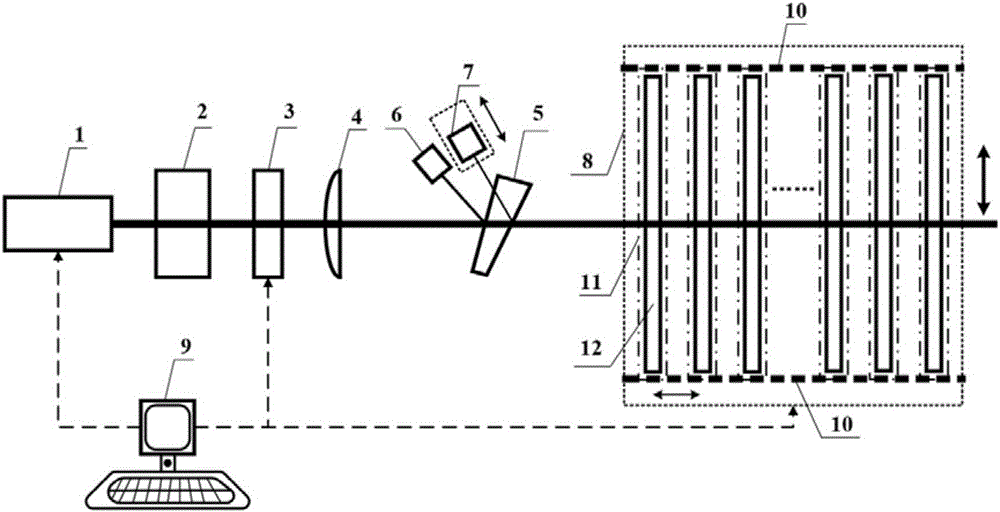

[0022] refer to figure 1 , a laser preprocessing device with transparent optical elements placed side by side, including a pulse laser 1 along the laser beam transmission direction, an energy attenuation system 2, an optical switch 3, a lens system 4, a beam splitting wedge 5, and a laser energy detector 6, CCD An imaging system 7 , a motorized mobile station 8 and a main control computer 9 .

[0023] The pulsed laser 1 is a Nd:YAG pulsed laser, and the focal length of the lens system 4 is 8m.

[0024] The main control computer 9 controls the pulse output of the pulse laser 1 and the opening and closing of the optical switch 3 through the data output card; the main control computer 9 controls the movement of the electric mobile platform 8 through the motion control card an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com