Improved cold glue spraying system of KDF2 forming machine

A technology of KDF2 and forming machine, which is applied to the surface coating liquid device, coating, etc., can solve the problems of non-uniform glue volume of filter rods, increased glue consumption, and unsynchronized glue running speed, etc., to achieve precise glue flow, The effect of improving quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

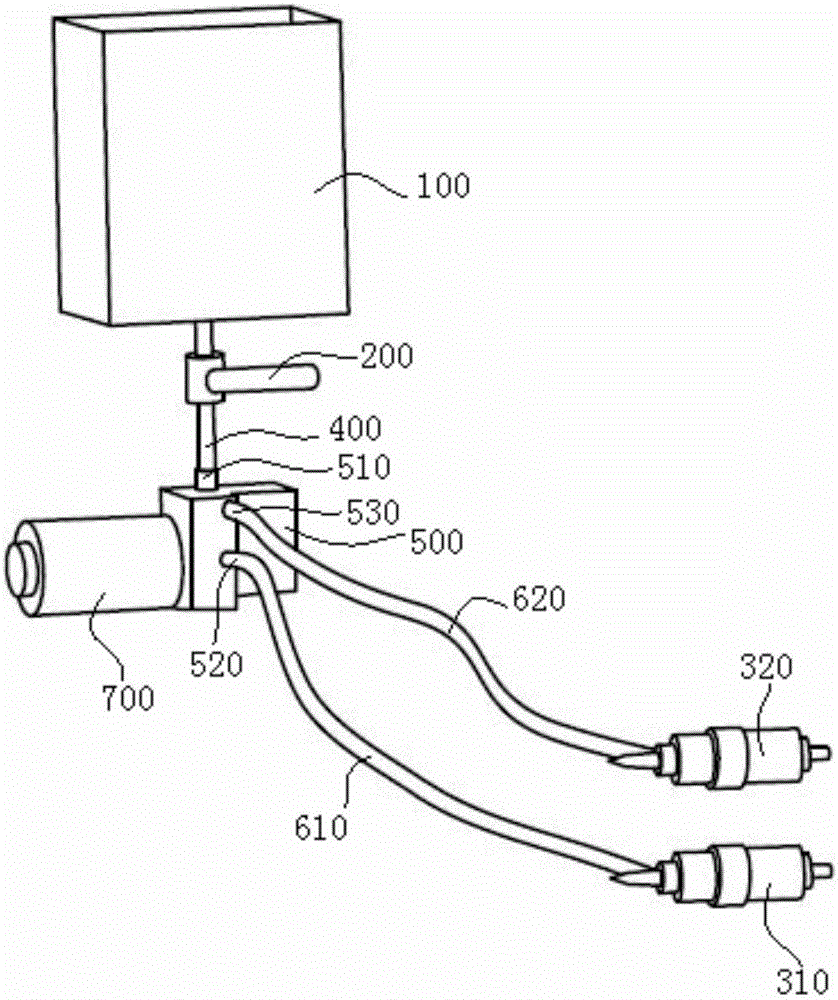

[0010] see figure 2 , an improved KDF2 molding machine cold glue spraying system shown in the figure, including a glue tank 100, a valve 200 and two cold glue nozzles 310, 320, a glue outlet pipe 400 is arranged at the bottom of the glue tank 100, and the valve 200 is installed on the rubber outlet pipe 400. It also includes a double-flow gear pump 500, the double-flow gear pump 500 has a glue inlet 510 and two glue outlets 520, 530, the glue inlet 510 on the double-flow gear pump 500 is connected with the glue outlet pipe 400, two cold glue nozzles 310 , 320 are respectively connected to a glue outlet 520 , 530 of the double-flow gear pump 500 through a hose 610 , 620 . The double-flow gear pump 500 is powered by a variable frequency motor 700, and the variable frequency motor 700 is connected to the host servo through a frequency converter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com