Preparation method of alkali lignin-based adsorbing material modified by sodium glutamate and application in removal of wastewater dyes

A technology of alkali lignin and sodium glutamate, which is applied in the direction of adsorption of water/sewage treatment, water pollutants, chemical instruments and methods, etc., can solve the problems of secondary pollution, limit the degree of wastewater treatment and utilization, etc., and achieve the improvement of adsorption effect , good adsorption effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of sodium glutamate modified alkali lignin-based adsorption material, comprising the following steps:

[0032] (1) Fully dissolve the industrial alkali lignin in the alkaline aqueous solution, control the pH of the alkaline aqueous solution to 11, stir for 2 hours, and filter with suction to remove insoluble impurities;

[0033] (2) Adjust the pH of the filtrate to 3 with hydrochloric acid solution, stir to make the alkali lignin fully analyzed;

[0034] (3) Suction filtration and washing to neutrality, and the obtained filter residue is dried in a constant temperature drying oven for 24 hours, and ground to obtain purified alkali lignin;

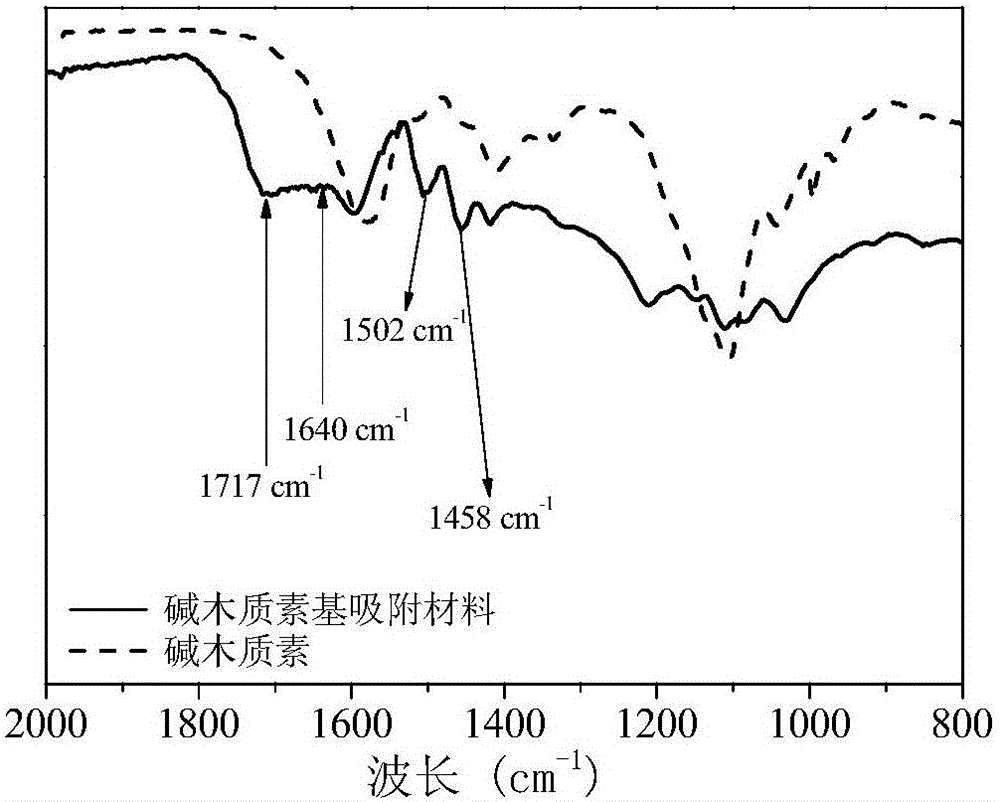

[0035] (4) Prepare the purified alkali lignin into a solution with a mass fraction of 5%, and then add sodium glutamate and formaldehyde to it, and the mass ratio of the purified alkali lignin, sodium glutamate and formaldehyde is 7.5: 7.5:5; react at 60°C for 6 hours;

[0036] (5) After the reaction is over, cool and adj...

Embodiment 2

[0042] A preparation method of sodium glutamate modified alkali lignin-based adsorption material, comprising the following steps:

[0043] (1) Fully dissolve the industrial alkali lignin in the alkaline aqueous solution, control the pH of the alkaline aqueous solution to 12, stir for 4 hours, and filter with suction to remove insoluble impurities;

[0044] (2) Adjust the pH of the filtrate to 2 with dilute sulfuric acid solution and stir to make the alkali lignin fully analyzed;

[0045] (3) Suction filtration and washing to neutrality, the obtained filter residue is dried in a constant temperature drying oven for 48 hours, and ground to obtain purified alkali lignin;

[0046] (4) The purified alkali lignin is formulated into a solution with a mass fraction of 10%, and then sodium glutamate and formaldehyde are added to it. The mass ratio of the purified alkali lignin, sodium glutamate and formaldehyde is 10: 10:9; react at 50°C for 8 hours;

[0047] (5) After the reaction is over, coo...

Embodiment 3

[0049] A preparation method of sodium glutamate modified alkali lignin-based adsorption material, comprising the following steps:

[0050] (1) Fully dissolve the industrial alkali lignin in the alkaline aqueous solution, control the pH of the alkaline aqueous solution to 11-12, stir for 2-5h, and filter with suction to remove insoluble impurities;

[0051] (2) Adjust the pH of the filtrate to 3~6, stir to make the alkali lignin fully analyzed;

[0052] (3) Suction filtration and washing to neutrality, the obtained filter residue is dried in a constant temperature drying oven for 24 to 48 hours, and then ground to obtain purified alkali lignin;

[0053] (4) The purified alkali lignin is formulated into a solution with a mass fraction of 4-20%, and then sodium glutamate and formaldehyde are added to it. The mass ratio of the purified alkali lignin, sodium glutamate and formaldehyde is 8:8:5; react at 50~80℃ for 4~20 hours;

[0054] (5) After the reaction is over, cool and adjust the pH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com