Nut grading and unshelling device

A shell breaking machine and nut technology, applied in grading, shelling, solid separation and other directions, can solve the problems of low shell breaking effect and efficiency, large space for equipment installation, unsatisfactory nut integrity rate, etc. Broken, easy to install and debug, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

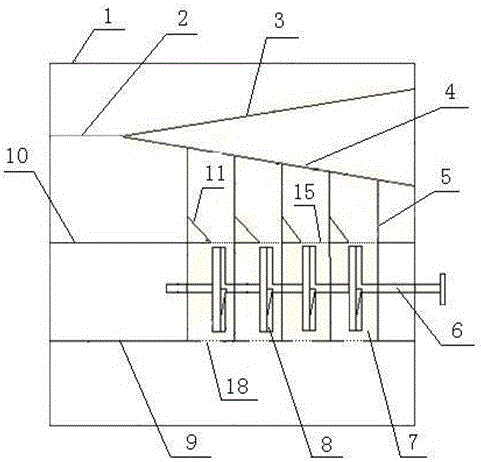

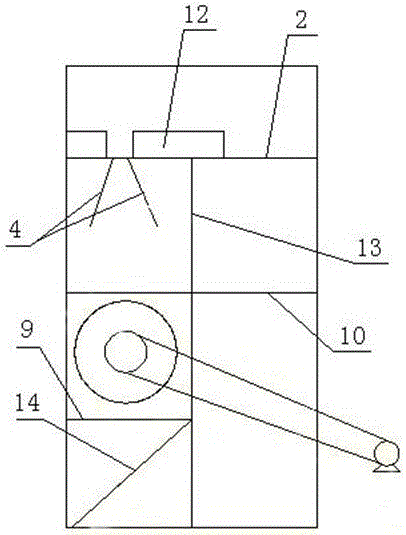

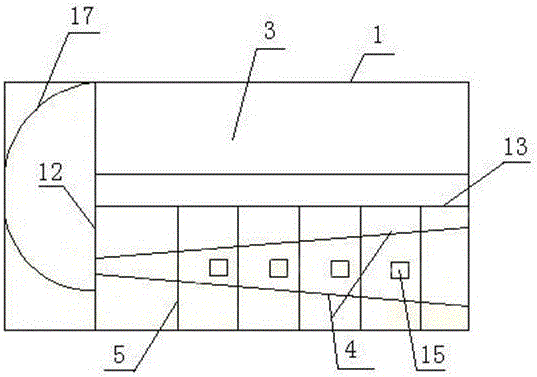

[0031] A nut grading and husking machine, the body (1) is a hollow box structure, composed of a grading area and a husking area. The grading area is composed of a conveying groove (3) and a first layer horizontally arranged in the upper part of the body. Plate (2), a rotating device (17) and a grading pipe (4) arranged on the horizontal plate of the first layer; the inlet end of the rotating device is connected with the outlet end of the conveying tank, and the outlet end of the rotating device is connected with The grading pipes are connected; the grading pipes are two round pipes arranged in a "eight" shape, and the angle between the grading pipes and the horizontal direction is 10 degrees; the shell breaking zone is set in the lower part of the grading zone, and the second Layer horizontal plate (10), longitudinal partition (5), lower fruit inclined plate (11), third layer horizontal plate (9), rear partition (13), rotating shaft (6) and crushing blades arranged on the rotati...

Embodiment 2

[0040] A nut grading and shelling machine. The body is a hollow box structure and consists of a grading zone and a shelling zone. The grading zone is composed of a conveying groove, a first horizontal plate arranged in the upper part of the body, and The rotary device on the horizontal plate and the grading pipe are composed; the inlet end of the rotary device is connected with the outlet end of the conveying tank, and the outlet end of the rotary device is connected with the grading pipe; the grading pipe is two "" shaped round pipe, the angle between the grading pipe and the horizontal direction is 22 degrees; the shell-breaking area is set in the lower part of the grading area, and consists of a second horizontal plate, a longitudinal partition, a lower fruit inclined plate, and a third It consists of a horizontal plate, a rear partition, a rotating shaft and a crushing blade arranged on the rotating shaft; there are at least two longitudinal partitions; the second horizontal...

Embodiment 3

[0053] A nut grading and shelling machine. The body is a hollow box structure and consists of a grading zone and a shelling zone. The grading zone is composed of a conveying groove, a first horizontal plate arranged in the upper part of the body, and The rotary device on the horizontal plate and the grading pipe are composed; the inlet end of the rotary device is connected with the outlet end of the conveying tank, and the outlet end of the rotary device is connected with the grading pipe; the grading pipe is two "" shaped round tube, the angle between the grading tube and the horizontal direction is 45 degrees; the shell-breaking zone is set in the lower part of the grading zone, and consists of a second horizontal plate, a longitudinal partition, a lower fruit inclined plate, and a third It consists of a horizontal plate, a rear partition, a rotating shaft and a crushing blade arranged on the rotating shaft; there are at least two longitudinal partitions; the second horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com