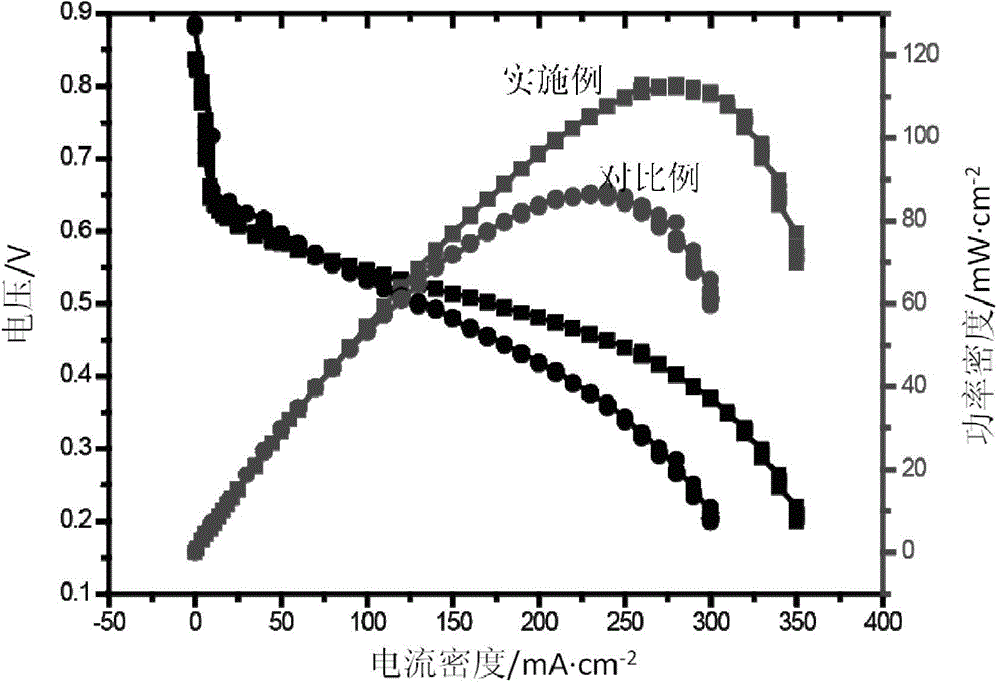

Fuel cell catalyst layer and membrane electrode subassembly and preparation method thereof

A membrane electrode assembly and fuel cell technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of poor product repetition and consistency, large catalyst loss rate, uneven thickness, etc., and achieve easy batch preparation, catalyst The effect of low loss rate and excellent uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

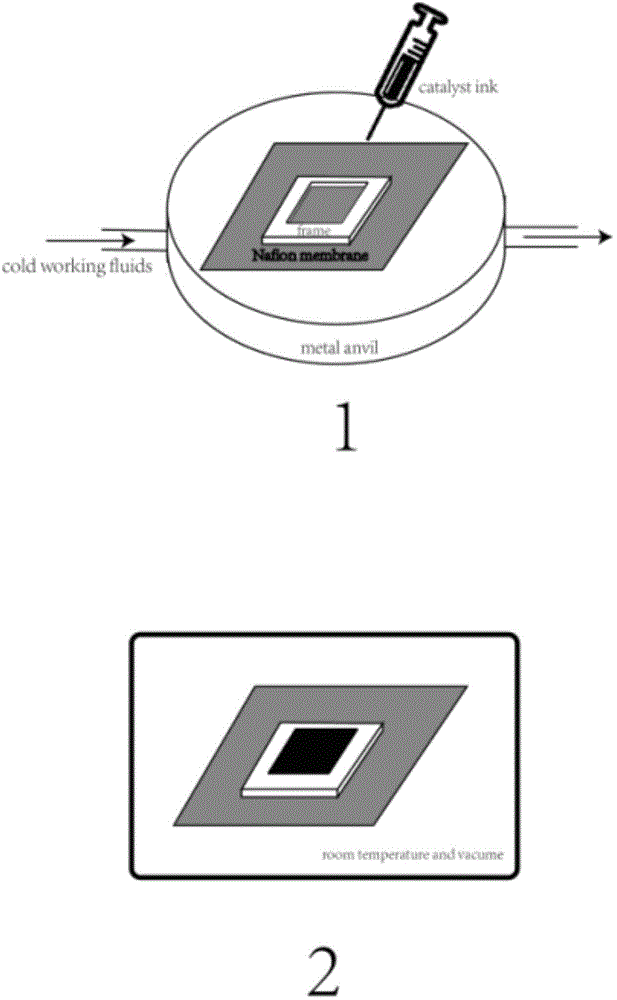

Embodiment 1

[0037]Disperse the anode catalyst powder (JM's PtRu black, 1:1) containing 480mg of noble metal platinum into a beaker filled with 24g of deionized water, and add the commercial solution containing 240mg of Nafion resin with a mass concentration of 10% to the aqueous dispersion of noble metal , the mixed suspension system was ultrasonically stirred and stirred for 2-15 minutes to obtain a uniform anode catalyst slurry.

[0038] Disperse the cathode catalyst powder (JM's carbon-supported platinum, 60wt%) containing 200mg of noble metal platinum into a beaker filled with 9.2g of deionized water, and add the commercial solution containing 60mg of Nafion resin with a mass concentration of 10% to the aqueous dispersion of the noble metal catalyst In the liquid, the mixed suspension system is ultrasonically stirred and stirred for 2-15 minutes to obtain a uniform cathode catalyst slurry.

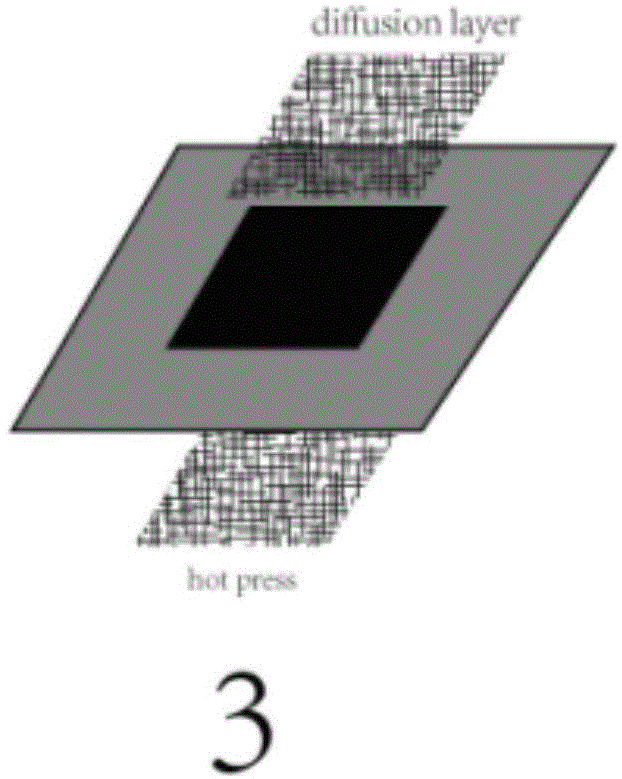

[0039] Nafion115 film is baked in a blast drying oven at 95°C for 12 hours. Use two identical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com