Making method of lithium ion battery

The technology of a lithium-ion battery and a manufacturing method is applied in the field of lithium-ion battery manufacturing, which can solve problems such as battery short circuit, achieve the effects of increasing electrical conductivity, low manufacturing cost, and suppressing the Jahn-Teller effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

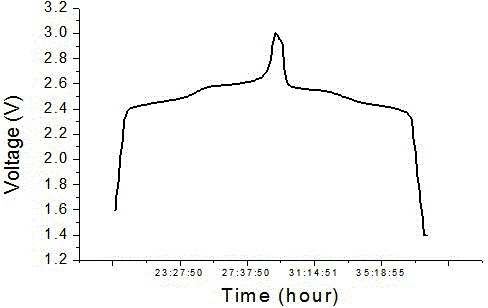

Examples

Embodiment 1

[0020] Prepare the positive electrode material. Weigh a certain amount of raw materials such as lithium nitrate, aluminum nitrate, manganese dioxide, and lithium fluoride according to the molar ratio of Li:Al:Mn:F of 1:0.03:1.95:0.05, put the above raw materials into a ball mill tank, and put them into Agate grinding balls, adding ethanol additives, ball milling for 4 hours to obtain a mixed slurry, which was transferred into a sagger, put into a resistance wire horizontal tube furnace, and heated at 5°C min -1 The heating rate was heated to 750 °C, kept for 10 hours, then cooled to room temperature with the furnace, and crushed to obtain Li 1.05 Al 0.03 mn 1.95 o 3.95 f 0.05 Cathode material;

[0021] Preparation of negative electrode materials. Lithium carbonate and nano-titanium dioxide were selected as raw materials, and the raw materials were weighed according to the Li:Ti molar ratio of 4:5. Put the above raw materials into a ball mill jar, add 20% sucrose of the ...

Embodiment 2

[0026] Prepare the positive electrode material. Weigh a certain amount of lithium carbonate, aluminum nitrate, manganese dioxide, lithium fluoride and other raw materials according to the molar ratio of Li:Al:Mn:F of 1:0.03:1.95:0.05, put the above raw materials into a ball mill jar, and put them into agate Grinding balls, adding ethanol additives, and ball milling for 4 hours to obtain a mixed slurry, which was transferred into a sagger, put into a resistance wire horizontal tube furnace, and heated at 10°C min -1 The heating rate is heated to 750 °C, kept for 12 hours, then cooled to room temperature with the furnace, and crushed to obtain Li 1.05 Al 0.03 mn 1.95 o 3.95 f 0.05 Cathode material;

[0027] Preparation of negative electrode materials. Lithium carbonate and nano-titanium dioxide were selected as raw materials, and the raw materials were weighed according to the Li:Ti molar ratio of 4:5. Put the above raw materials into a ball mill jar, add 30% sucrose of t...

Embodiment 3

[0032] Prepare the positive electrode material. Weigh a certain amount of raw materials such as lithium carbonate, aluminum nitrate, manganese acetate, and lithium fluoride according to the molar ratio of Li:Al:Mn:F of 1:0.03:1.95:0.05, put the above raw materials into a ball mill jar, and put them into agate for grinding balls, added ethanol additives, and ball milled for 3 hours to obtain a mixed slurry, which was transferred into a sagger, put into a resistance wire horizontal tube furnace, and heated at 10°C min -1 The heating rate is heated to 700 °C, kept for 8 hours, then cooled to room temperature with the furnace, and crushed to obtain Li 1.05 Al 0.03 mn 1.95 o 3.95 f 0.05 Cathode material;

[0033] Preparation of negative electrode materials. Lithium carbonate and nano-titanium dioxide were selected as raw materials, and the raw materials were weighed according to the Li:Ti molar ratio of 4:5. Put the above raw materials into a ball mill jar, add sucrose with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com