Preparation method of porous nitrogen-rich carbon fiber electrode

A carbon fiber electrode and carbon fiber technology, which is applied in the chemical characteristics of fibers, hybrid capacitor electrodes, and hybrid/electric double layer capacitor manufacturing, etc. Superior electrochemical performance, rich nitrogen content, and small nitrogen loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

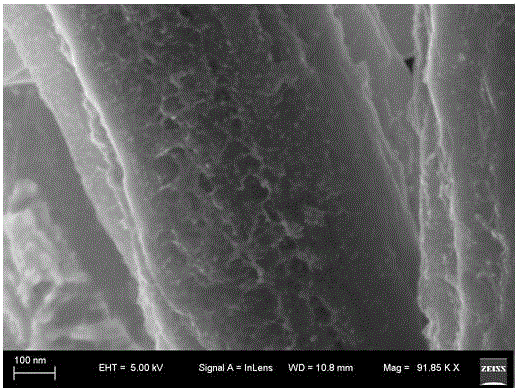

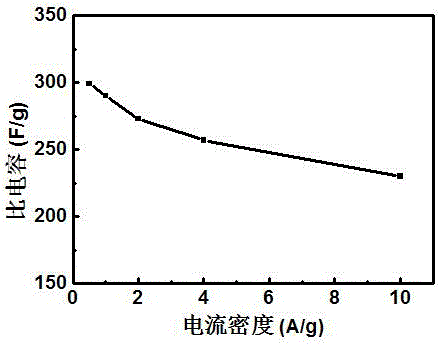

Image

Examples

Embodiment 1

[0032] 1. Preparation of spinning solution: Add 2 g of polyacrylonitrile into 18 g of N,N-dimethylformamide, dissolve and add 0.5 g of melamine resin and 0.5 g of polyethylene glycol to dissolve to obtain spinning solution.

[0033] 2. Preparation of PEG / MF / PAN composite fiber: high-voltage electrospinning technology was used for spinning, wherein the spinning voltage was 20kV, the injection speed was 0.3mm / min, the receiving distance was 17cm, the spinning temperature was 40°C, and the humidity was 30%.

[0034] 3. Pre-oxidation: Put the PEG / MF / PAN composite fiber in the air atmosphere, raise the temperature to 250°C at a heating rate of 5°C / min, keep it for 2 hours, and then lower it to room temperature at a cooling rate of 5°C / min.

[0035] 4. Carbonization: Place the pre-oxidized PEG / MF / PAN composite fiber in a nitrogen or argon atmosphere, raise the temperature to 800°C at a rate of 5°C / min, keep it warm for 2 hours, and then cool it down at a rate of 5°C / min Speed dow...

Embodiment 2

[0038] 1. Preparation of spinning solution: add 2g of polyacrylonitrile to 20g of N,N-dimethylformamide, dissolve and add 1g of melamine resin and 0.5g of polyethylene glycol to dissolve to obtain spinning solution.

[0039] 2. Preparation of PEG / MF / PAN composite fiber: high-voltage electrospinning technology was used for spinning, wherein the spinning voltage was 17kV, the injection speed was 0.1mm / min, the receiving distance was 20cm, the spinning temperature was 40°C, and the humidity was 30%.

[0040] 3. Pre-oxidation: Put the PEG / MF / PAN composite fiber in the air atmosphere, raise the temperature to 250°C at a heating rate of 5°C / min, keep it for 2 hours, and then lower it to room temperature at a cooling rate of 5°C / min.

[0041] 4. Carbonization: Place the pre-oxidized PEG / MF / PAN composite fiber in a nitrogen or argon atmosphere, raise the temperature to 800°C at a rate of 3°C / min, keep it warm for 2 hours, and then cool it down at a rate of 3°C / min Speed down to nor...

Embodiment 3

[0044] 1. Preparation of spinning solution: 2 g of polyacrylonitrile was added to 18 g of N,N-dimethylformamide, and after dissolving, 1.5 g of melamine resin and 1.0 g of polyethylene glycol were added to dissolve to obtain spinning solution.

[0045] 2. Preparation of PEG / MF / PAN composite fiber: high-voltage electrospinning technology is used for spinning, wherein the spinning voltage is 20kV, the injection speed is 0.7mm / min, the receiving distance is 20cm, the spinning temperature is 20°C, and the humidity is 30%.

[0046]3. Pre-oxidation: Put the PEG / MF / PAN composite fiber in the air atmosphere, raise the temperature to 250°C at a heating rate of 3°C / min, keep it for 2 hours, and then lower it to room temperature at a cooling rate of 3°C / min.

[0047] 4. Carbonization: Place the pre-oxidized PEG / MF / PAN composite fiber in a nitrogen or argon atmosphere, raise the temperature to 800°C at a rate of 1°C / min, keep it warm for 2 hours, and then cool it down at a rate of 2°C / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com