Gas producing chemical for automobile air bag gas generator and preparation method of gas producing chemical

A gas generator and automobile safety technology, which is applied in the production of compressed gas, attacking equipment, etc., can solve the problems of injuring the occupants in the vehicle, precipitation or powdering of medicines, splashing metal fragments, etc. The effect of strong steps and simple raw material handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

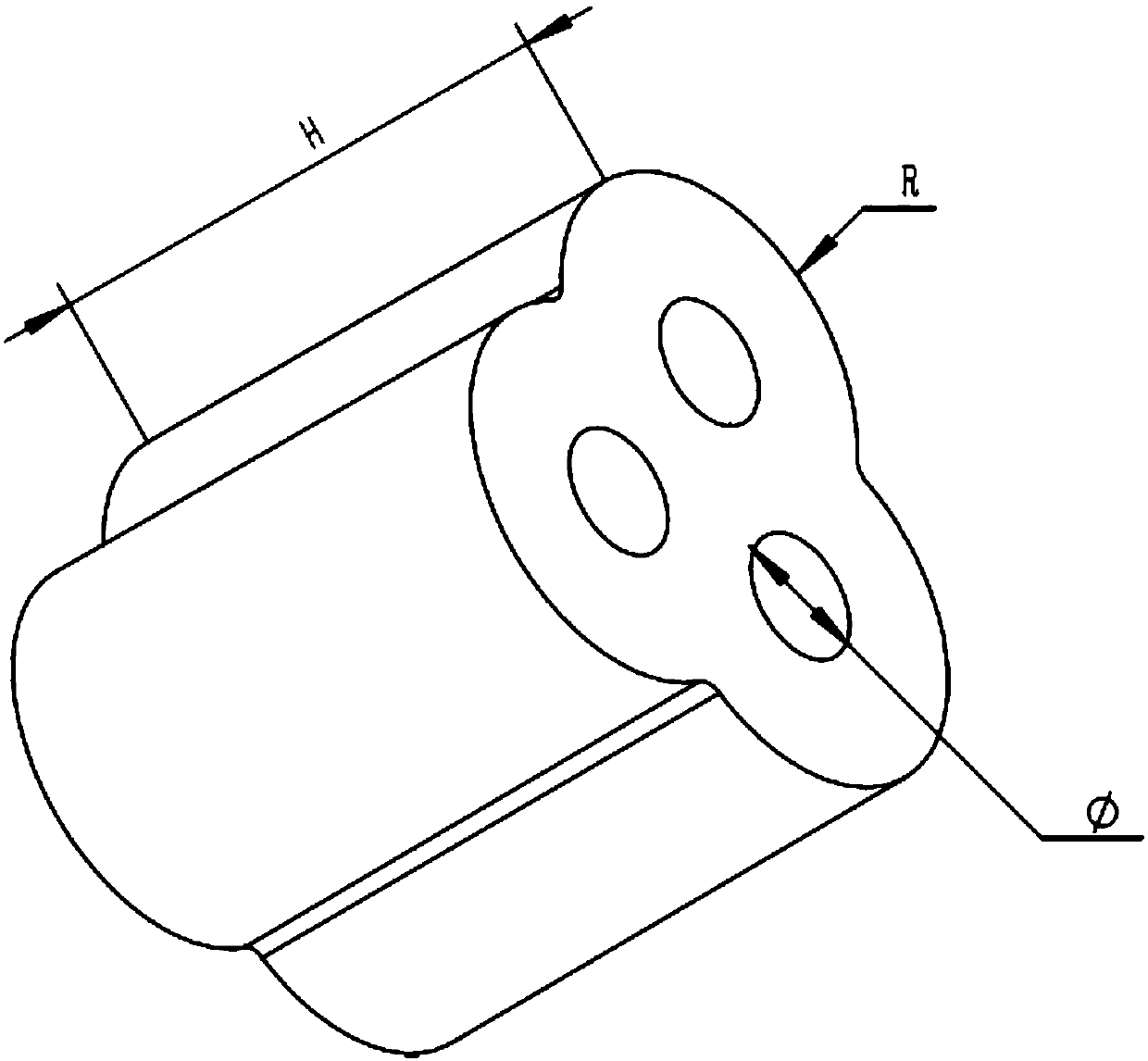

[0040] A preparation method of a gas-generating drug used in an automobile airbag gas generator according to the invention comprises the following components in terms of the mass percentage of the gas-generating drug: 45% to 63.2% of a combustible agent, 0.1% to 5% of a viscous mixture, 35%-50% oxidizing agent; the preparation method includes the following steps: weighing each component according to the above ratio, dispersing the combustible agent, adhesive, and oxidizing agent in the solution, adding them to a high-efficiency wet mixer, mixing uniformly and cutting Make small granules, then use a swing granulator to granulate, then lay the granules on a medicine tray and dry them, and finally add auxiliary additives to the dried granules, and then compress them into tablets with a rotary tablet press. Adding auxiliary additives The mass is 0.1%-0.5% of the sum of the mass of combustible agent, binder and oxidant.

[0041] Preferably, the solution is a mixture of absolute alc...

Embodiment 1

[0050] The gas generating drug of this example includes potassium perchlorate 17% with an average particle size of 16.3um, ultrafine guanidine nitrate with an average particle size of 5.3μm 52%, potassium nitrate with an average particle size of 16.7um 19%, and an average particle size of 5 -Aminotetrazole 10%, nitrocellulose 2% are formulated into a solution, and boron nitride 0.2% is added.

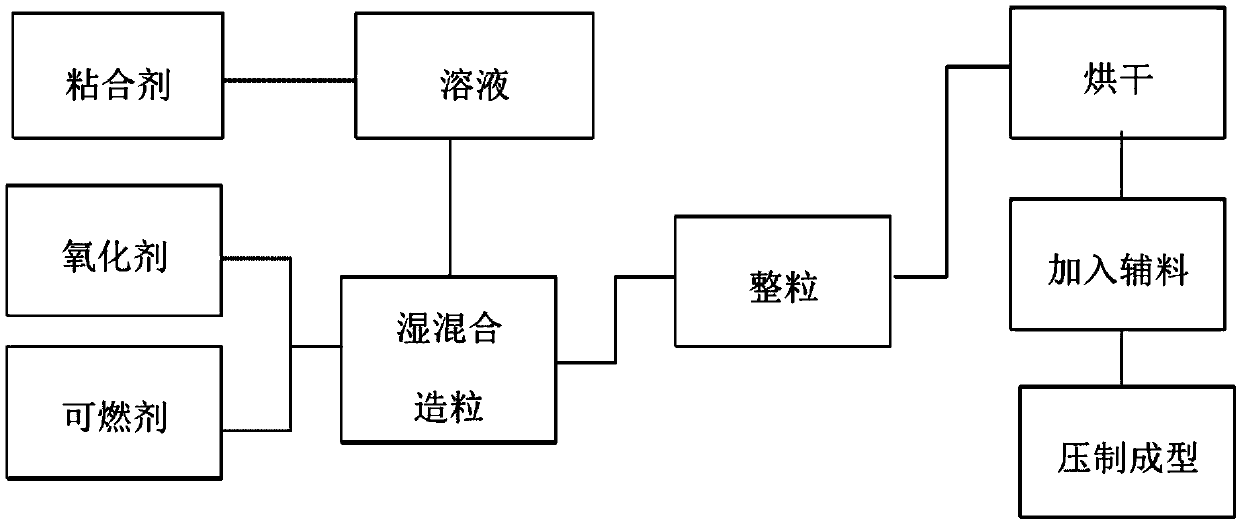

[0051] The preparation process of the gas-producing drug is as follows: figure 1 shown as:

[0052] Weigh 17% of potassium perchlorate with an average particle size of 16.3um, 52% of ultrafine guanidine nitrate with an average particle size of 5.3μm, 19% of potassium nitrate with an average particle size of 16.7um, and 10% of 5-aminotetrazole with an average particle size of less than 10μm , nitrocellulose 2% and boron nitride 0.2%, potassium perchlorate and potassium nitrate need to add a certain amount of white carbon black for ball milling and sieving before use, pretreat the irregu...

Embodiment 2

[0064] The gas generating drug of this example includes potassium perchlorate 17% with an average particle size of 16.3um, ultrafine guanidine nitrate with an average particle size of 5.3μm 52%, potassium nitrate with an average particle size of 16.7um 19%, and an average particle size of 5 -Aminotetrazole 10%, nitrocellulose 2% is formulated into a solution, and white carbon black 0.15% is added.

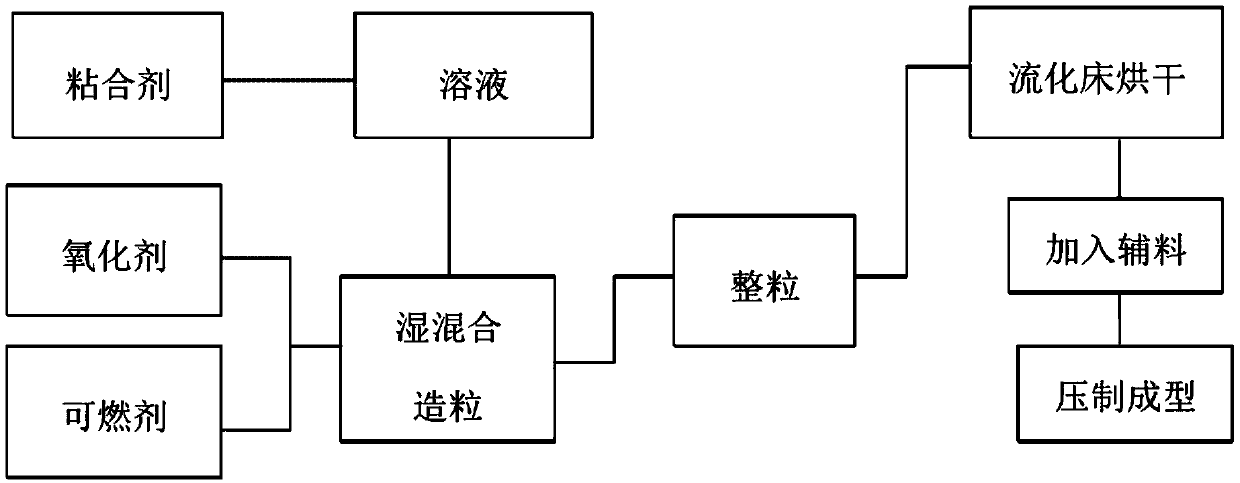

[0065] The preparation process of the gas-producing drug is as follows: figure 2 shown as:

[0066] Weigh 17% of potassium perchlorate with an average particle size of 16.3um, 52% of ultrafine guanidine nitrate with an average particle size of 5.3μm, 19% of potassium nitrate with an average particle size of 16.7um, and 10% of 5-aminotetrazole with an average particle size of less than 10μm , nitrocellulose 2% and silica 0.15%. Potassium perchlorate and potassium nitrate need to add a certain amount of white carbon black for ball milling and sieving treatment before use, and pret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com