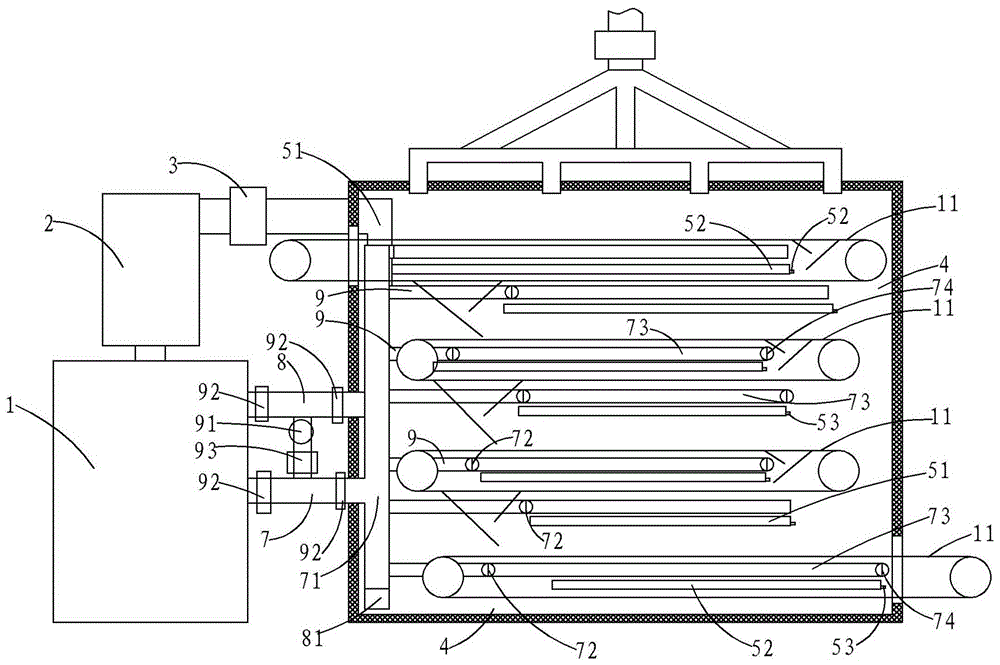

Rapid briquette coal drying system and briquette coal drying furnace

A rapid drying and drying furnace technology, applied in drying, dryer, drying solid materials, etc., can solve the problems of slow oil temperature drop, inability to drain hot oil, and unbalanced oil flow, so as to increase fluid flow Internal and external exchange, increase the drying effect, increase the effect of liquid turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

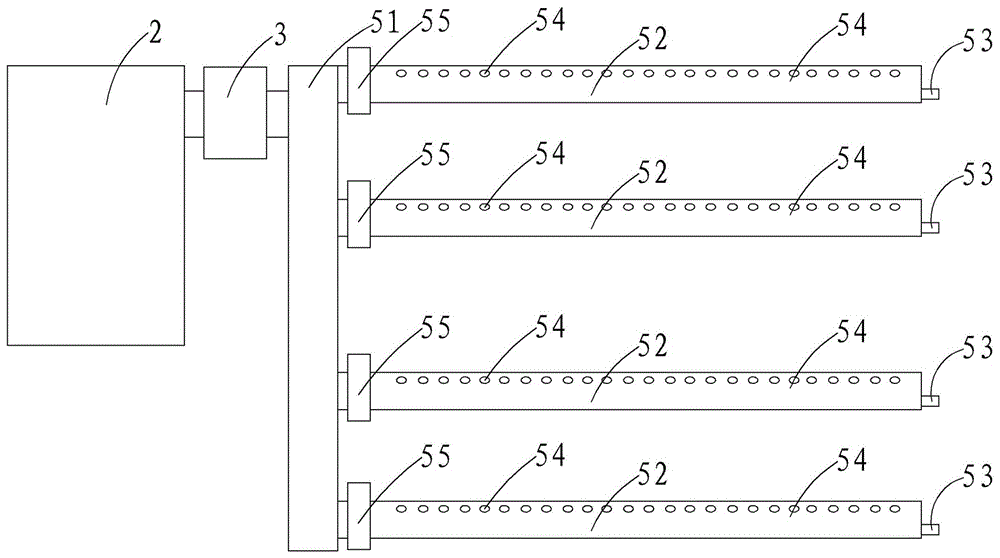

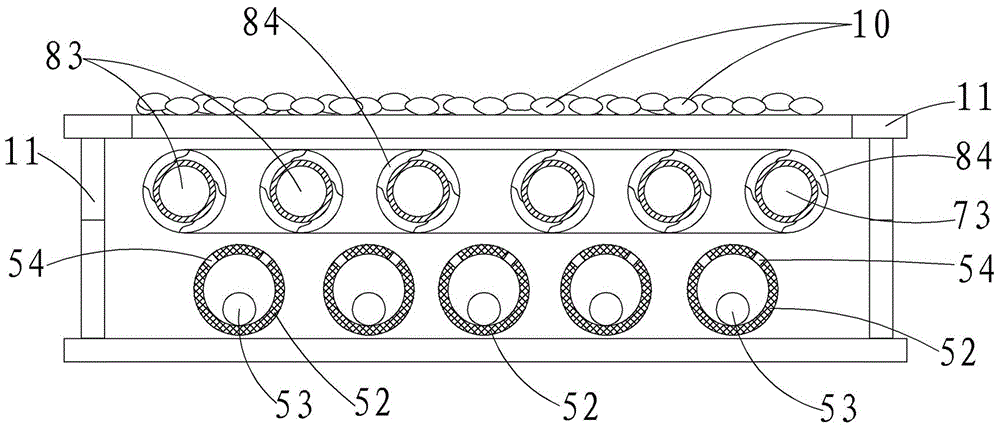

[0041] Embodiment 2, the difference from Embodiment 1 is that the air distribution hole 54 is an arc-shaped hole and is located at the top of the branch air pipe 52, the air distribution hole 54 is a radially opened hole, and a plurality of the air distribution holes The holes 54 are evenly distributed axially on the branch air duct 52, and the central angle corresponding to the air distribution hole 54 is 45°-120°; Figure 6 As mentioned above, the central angle corresponding to the air distribution hole 54 is called β.

[0042] The airflow in the flue of the boiler is high-temperature flue gas with spark particles, which must be dust-removed to filter out the combustion particles. During the dust-removal process, the temperature of the flue gas decreases, and it can be directly sent to the drying chamber 4 through the induced draft fan 3 through the pipe. Inside, the working temperature in the drying chamber 4 is 200-235 degrees, and the temperature of the airflow passing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com