Circular vehicle-mounted LED emergency lighting lamp

A lighting and vehicle-mounted technology, applied in lighting devices, fixed lighting devices, lighting and heating equipment, etc., can solve the problems of narrow lighting range, accelerated aging, and high processing costs, saving power cords and related structures, and reducing the amount of molds , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

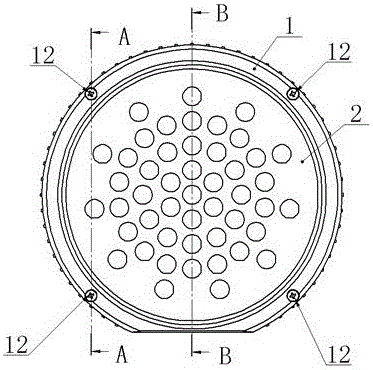

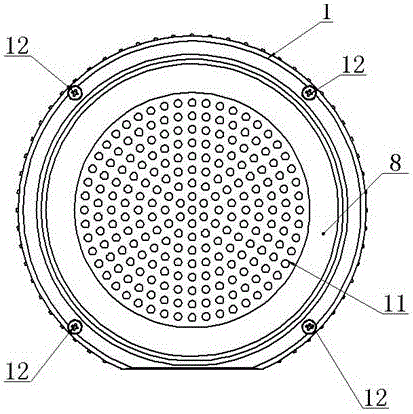

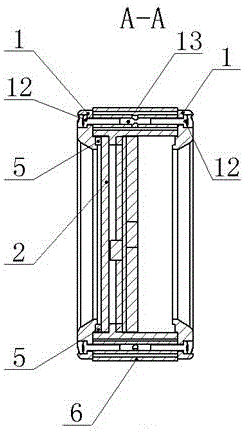

[0049] Such as Figure 1 to Figure 11 As shown, the present invention includes a circular end cover 1 using die-cast aluminum, a transparent glass 2, a lens 3, a cylindrical heat sink 6 and a columnar heat sink 11, such as Figure 5 and Figure 6 As shown, one side of the circular end cap 1 is provided with a first step 1-1 of a circular end cap, a second step 1-2 of a circular end cap, a third step 1-3 of a circular end cap and a round Through hole 1-6 in the center of the end cover, stepped screw holes 1-4 are provided on the vertical end surface of the third step 1-3 of the circular end cover, and a bottom plane of the circular end cover is provided at the bottom of the outer wall of the circular end cover 1 1-5, the circular end cap 1 has versatility, and simultaneously serves as a symmetrical front end cap and rear end cap, such as Figure 7 ~ Figure 9 As shown, the outer wall of the cylindrical radiator 6 is radially provided with cooling fins 6-1, and the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com