High-efficient multi-stage cyclone self-cleaning separator and application method

A separator and high-efficiency technology, applied in separation methods, chemical instruments and methods, filtration separation, etc., can solve the problems of losing the filtering effect of the filter, reducing the filtering area of the sand control filter, and shortening the separation effect of the separator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

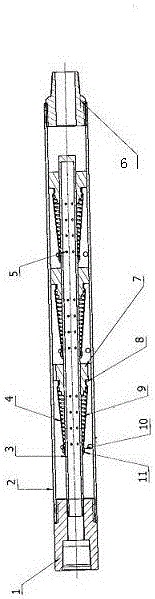

[0014] Embodiment 1, the present invention is made up of upper joint 1, outer pipe 2, inner pipe 3, filter screen 4, lower joint 6, spring support 7, filter screen large hoop 8, spring 9, filter screen small hoop 10, The upper fixing ring 11 is connected, the upper end of the outer tube 2 is connected with the upper joint 1, and the lower end of the outer tube 2 is connected with the lower joint 6; there is an inner tube 3 in the middle of the outer tube 2; the spring support 7 is respectively fixed on the inner tube 3 the outer periphery of the spring 9; the big end of the spring 9 is fixed on the spring support 7; the small end of the spring 9 is fixed on the upper fixed ring 11, the slip ring is on the outer periphery of the inner tube 3, the filter screen 4 is at the outer end of the spring 9, and the upper end of the filter screen 4 Be fixed on slip ring periphery with filter screen small hoop ring 10, filter screen 4 lower ends are fixed on spring support 7 outer peripher...

Embodiment 2

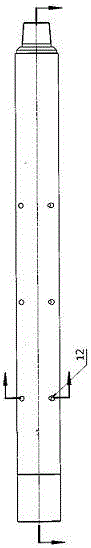

[0015] Embodiment 2. The upper end of the outer tube 2 is provided with an outer tube liquid inlet hole 12, and the outer tube liquid inlet hole 12 is a circumferential tangential liquid inlet hole.

Embodiment 3

[0016] Embodiment 3. The inner pipe 3 is provided with inner pipe liquid inlet holes 5 at the upper and lower sides; the liquid outlet hole of the inner pipe 3 communicates with the liquid inlet hole of the oil well pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com