Gate

A gate and valve technology, applied in the field of water treatment equipment, can solve the problems of downstream water treatment equipment impact, large friction between rubber strip and gate frame, gate leakage, etc., to reduce the impact of downstream equipment, safe and reliable gate opening and closing, reduce Effects of small stress effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

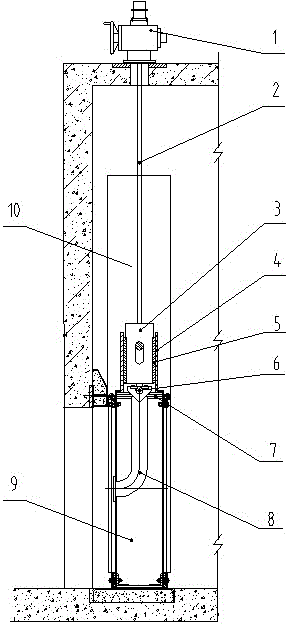

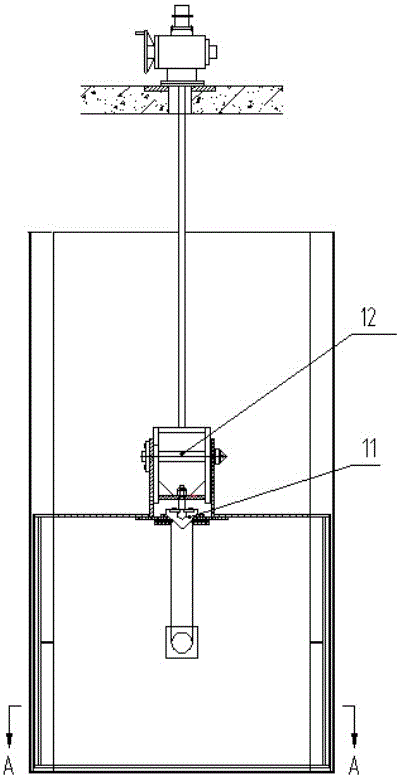

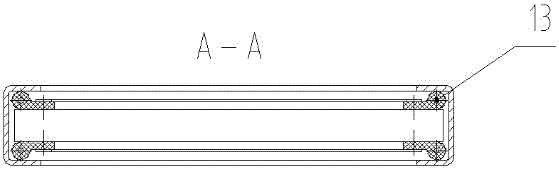

[0020] figure 1 It is a schematic diagram of the side structure of the present invention. like figure 1 As shown, the steel maintenance gate of the present invention includes a hoist 1, a transmission screw 2, a movable hanger 3, a hanger 4, a ball end boom 6, a valve 11, a water stop pad 7, an overflow pipe 8, and a gate body 9 and gate frame 10. The gate body 9 is installed in the gate frame 10, and a sealing strip is installed on both sides to cooperate with the gate frame 10. In the present invention, the sealing strip adopts a water-stop rubber strip 13. The overflow pipe 8 is installed in the gate body 9 and is connected to both sides of the gate body 9, that is, the overflow pipe 8 is connected to the upstream equipment and the downstream equipment; One side of 8 outlets is equipped with water-stop pad 7. Hanger 4 is fixedly installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com