A method of combining baled straw and livestock and poultry manure to produce biogas

A technology for livestock and poultry manure and biogas production, which is applied in fermentation, biological sludge treatment, sludge treatment, etc., can solve the problem of large-scale utilization of unfavorable crop straw and livestock and poultry manure, increased operating costs of biogas projects, and straw utilization rate of less than 50% % and other issues, to achieve the effect of increasing the volumetric gas production rate, increasing the cumulative gas production, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

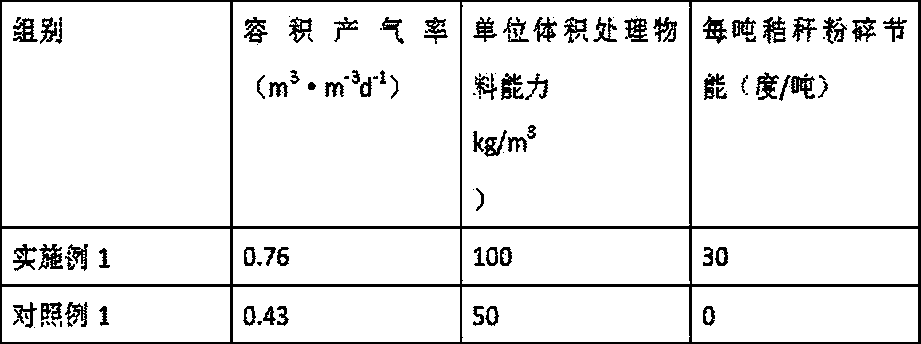

Examples

Embodiment 1

[0028] The reactor parameters used in this embodiment are as follows: the reactor parameters used are as follows:

[0029]

[0030] The fermentation process is as figure 1 As shown, the specific steps are as follows:

[0031] (1) Straw pretreatment

[0032] After the rice straw is harvested, collect the straw, inoculate the biogas fermentation agent according to the mass ratio of 2-3‰, and use the straw baler to compress the straw into a square grass block and bundle it. The volume of the grass block is ≤1m 3 , the density is 100kg / m 3 , the measured water content is 12.29%;

[0033] Stack the bundled straw and grass blocks in the reactor, and place the grass blocks in a staggered manner, leaving a gap of 3-5 cm; according to the method of spraying a layer of livestock and poultry manure for each layer of grass blocks, Stack up, straw:fresh pig manure dry matter ratio 1:1, C / N ratio 30:1, add lime powder to adjust pH=7.0;

[0034] After stacking, close the reactor door...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com