Rare earth doping fluozirconate luminescent material and preparing method thereof

A technology of fluorozirconate and rare earth doping, which is applied in the direction of luminescent materials, chemical instruments and methods, etc. It can solve the problems of product reunion, non-luminescence, and inaccessibility, and achieve the effect of good crystallinity and easy dispersion of particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

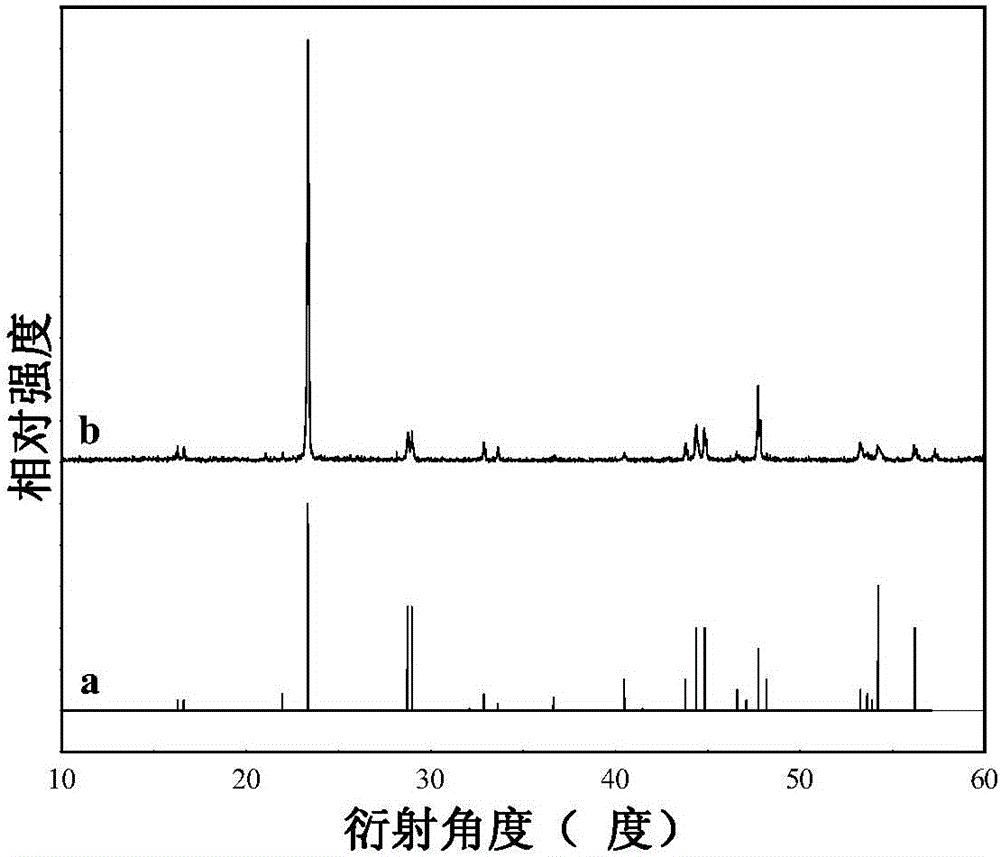

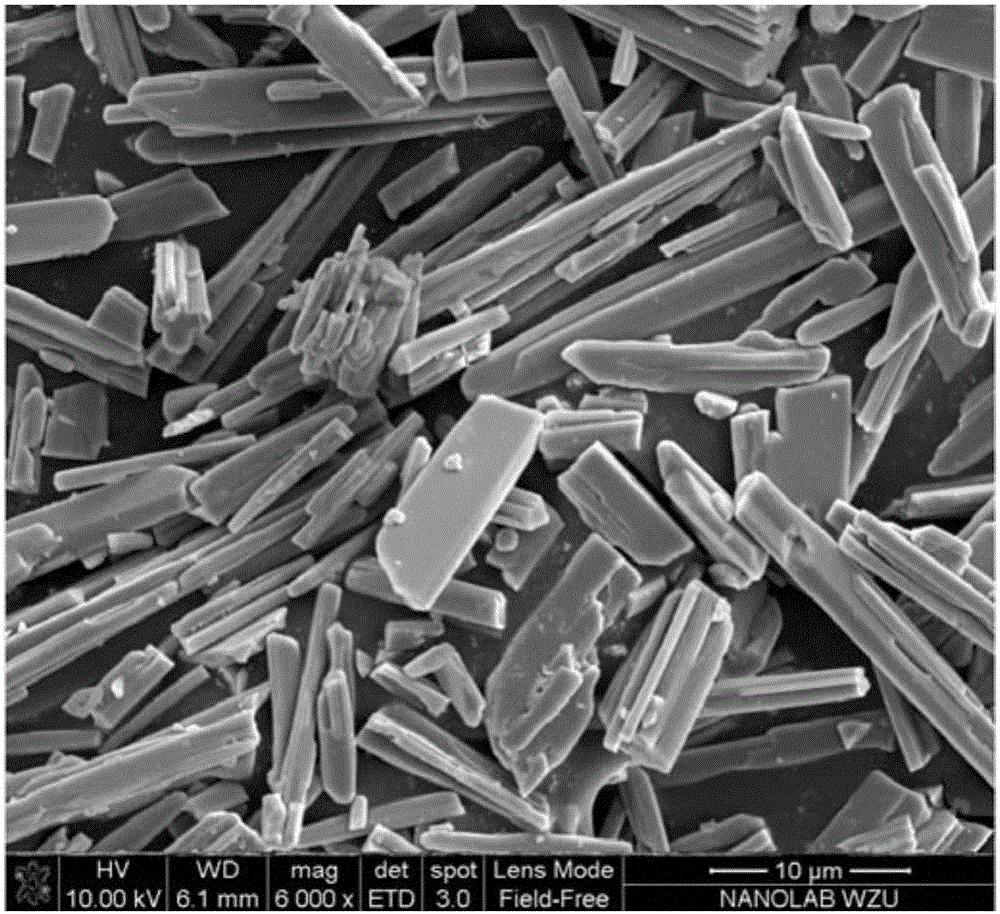

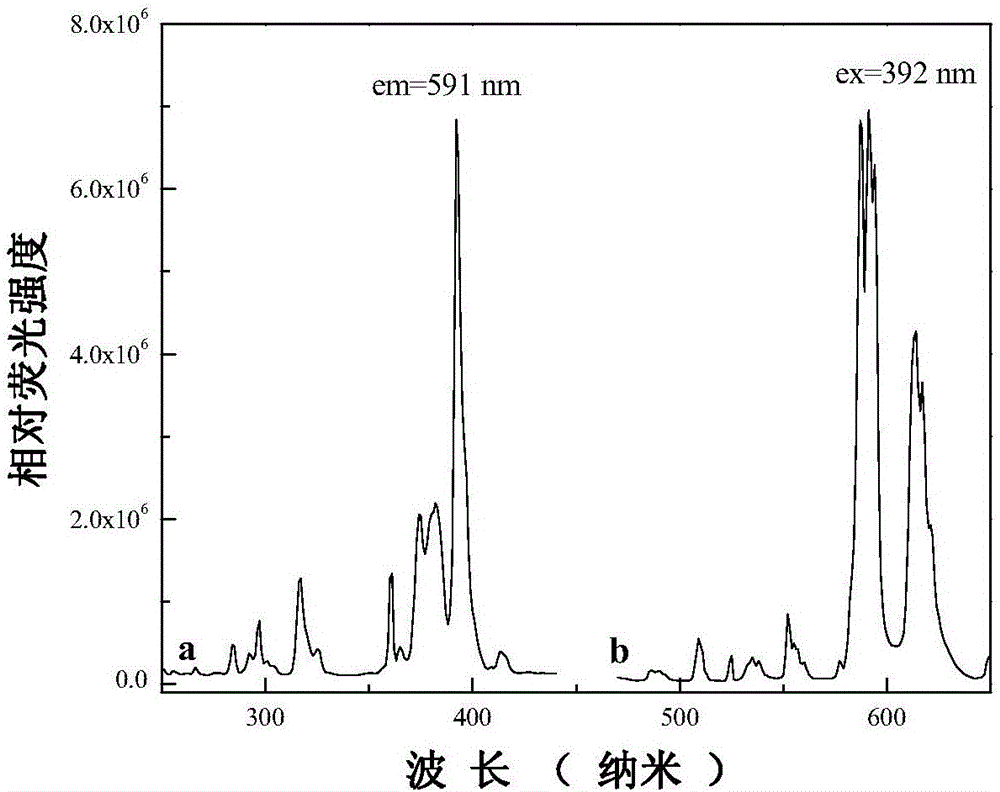

[0024] Mole ratio Sr: [ZrF 6 ]: Eu=0.98:1:0.02, accurately weigh the solid strontium fluoride SrF with an electronic balance 2 (analytical pure) with europium oxide Eu 2 o 3 (4N), put into the polytetrafluoroethylene reactor lining, accurately measure fluozirconic acid with a pipette and add, then add deionized water to make the total volume of the reaction system reach 40mL (accounting for 80% of the inner volume of the reactor), Magnetic stirring was performed for 15 minutes, and the liner containing the mixture was placed in a closed stainless steel reaction kettle. The reaction kettle was transferred to an oven and kept at 180° C. for 12 hours. After the reaction is completed, it is cooled and dried naturally after suction filtration, and the total product is about 3 grams. The product emits bright red fluorescence under near-ultraviolet irradiation. figure 1 The XRD shows that the product is a pure phase of SrZrF 6 , slightly doped with Eu 3+ The crystal structure ...

Embodiment 2

[0027] Mole ratio Sr: [ZrF 6 ]: Eu=0.995:1:0.005, accurately weigh the solid strontium fluoride SrF with an electronic balance 2(analytical pure) with europium oxide Eu 2 o 3 (4N), put into the polytetrafluoroethylene reactor lining, accurately measure fluozirconic acid with a pipette and add, then add deionized water to make the total volume of the reaction system reach 40mL (accounting for 80% of the inner volume of the reactor), Magnetic stirring was performed for 10 minutes, and the liner containing the mixture was placed in a closed stainless steel reaction kettle. The reaction kettle was transferred to an oven and kept at 220° C. for 4 hours. After the reaction is completed, it is cooled and dried naturally after suction filtration, and the total product is about 3 grams. The product emits bright red fluorescence under near-ultraviolet irradiation. Its excitation and emission spectra are image 3 Basically similar.

Embodiment 3

[0029] Mole ratio Sr: [ZrF 6 ]: Eu=0.93:1:0.07, accurately weigh the solid strontium fluoride SrF with an electronic balance 2 (analytical pure) with europium oxide Eu 2 o 3 (4N), put into the polytetrafluoroethylene reactor lining, accurately measure fluozirconic acid with a pipette and add, then add deionized water to make the total volume of the reaction system reach 40mL (accounting for 80% of the inner volume of the reactor), Magnetic stirring was performed for 10 minutes, and the liner containing the mixture was placed in a closed stainless steel reaction kettle. The reaction kettle was transferred to an oven and kept at 220° C. for 4 hours. After the reaction is completed, it is cooled and dried naturally after suction filtration, and the total product is about 3 grams. The product emits bright red fluorescence under near-ultraviolet irradiation. Its excitation and emission spectra are image 3 Basically similar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com