Polymerizable compound containing benzothiophene

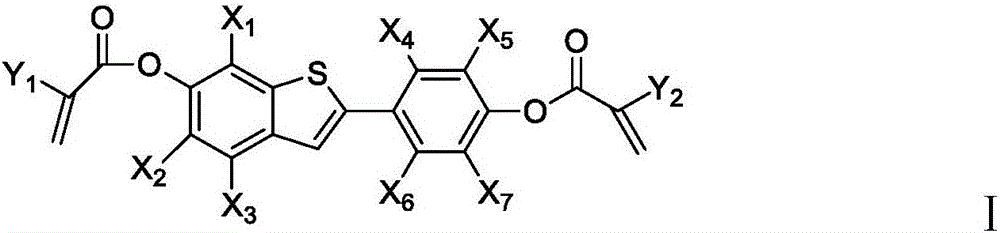

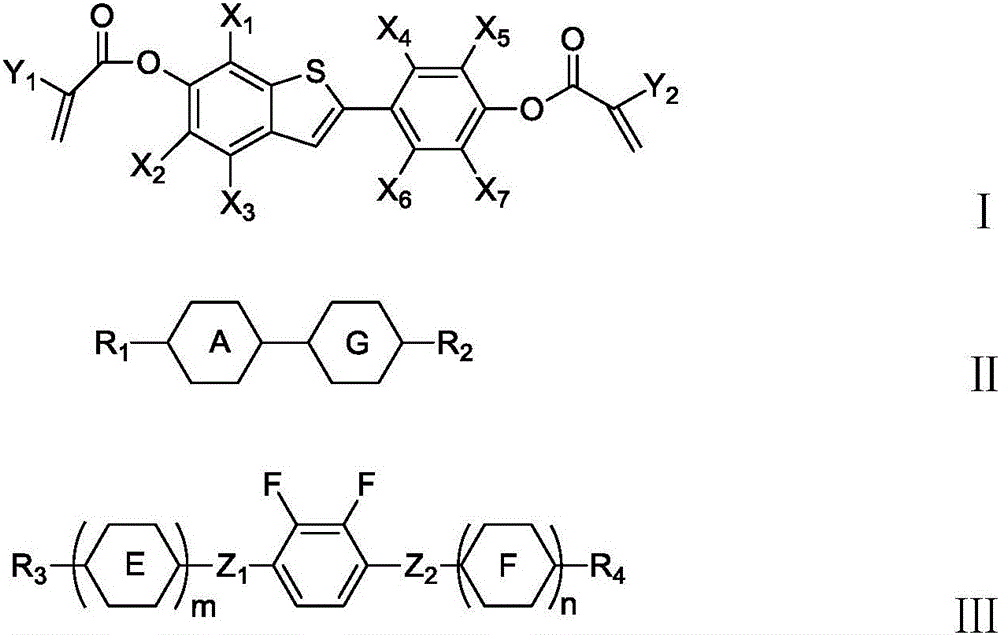

A technology for polymerizing compounds and compounds, applied in the fields of organic chemistry, chemical instruments and methods, instruments, etc., can solve the problems of poor uniformity and low TFT display, and achieve the effects of less monomer residue, high charge retention rate, and high polymerization activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] step one

[0085] Add 0.056mol (1-a) 15.12g and dichloromethane 200g into a 500ml three-necked flask, cool the reaction solution to 0-5°C, drop 0.067mol16.87g of boron tribromide, and react overnight.

[0086] The reaction solution was poured into a beaker filled with 500g of water, and separated. The aqueous phase was extracted three times with 300 g of dichloromethane. The organic phase was washed twice with 300 g of water. The organic phase was evaporated to dryness to obtain 12.1 g of product 1-b, yield: 89.3%

[0087] Jump straight into the next step.

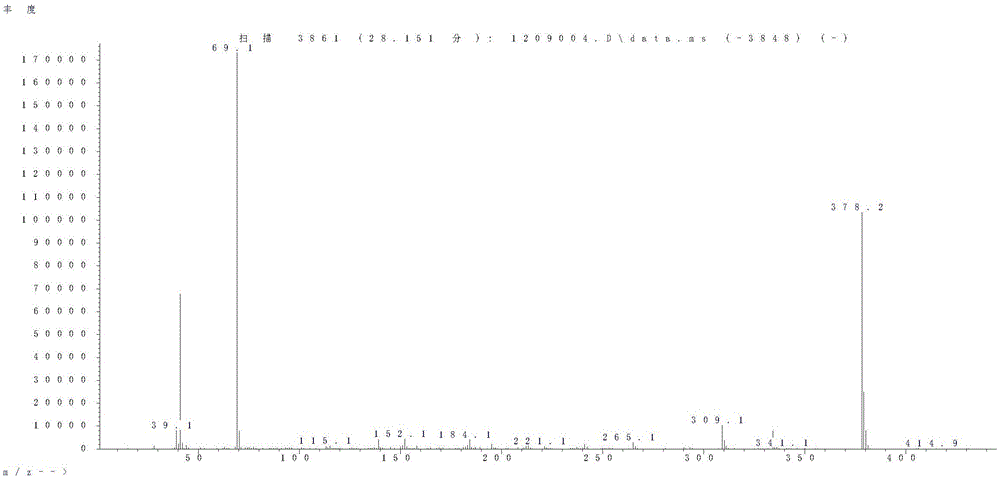

[0088] Gc-MS: see attached picture 1

[0089] step two

[0090]

[0091] Add 0.05mol1-b12.1g, 250g of dichloromethane, 0.6g of DMAP, 27g of DCC, 11g of methacrylic acid into a 500ml three-necked flask, and react overnight at 25°C.

[0092]The reaction solution was poured into a beaker filled with 500g of water, and separated. The aqueous phase was extracted three times with 250 g of dichloromethane. The...

Embodiment 2

[0095]

[0096] Add 0.05mol1-b12.1g, 250g of dichloromethane, 0.6g of DMAP, 27g of DCC, 15g of trifluoromethacrylic acid into a 500ml three-necked flask, and react overnight at 25°C.

[0097] The reaction solution was poured into a beaker filled with 500g of water, and separated. The aqueous phase was extracted three times with 250 g of dichloromethane. The organic phase was washed twice with 250 g of water.

[0098] The solvent was evaporated to dryness under reduced pressure, dissolved in toluene, passed through a silica gel chromatography column, and the solvent was evaporated to dryness. Toluene was recrystallized 3 times. 12.5 g of I-2 was obtained, yield 51%, Gc: 99.81%.

[0099] The compounds of Examples I-1 and I-2 have the advantage of longer ultraviolet absorption wavelengths, which can reduce damage to liquid crystal molecules during the process of forming an alignment layer by ultraviolet irradiation polymerization.

Embodiment 3

[0101]

[0102]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com