Production technology of steel band-enhanced polyethylene screw corrugated pipe

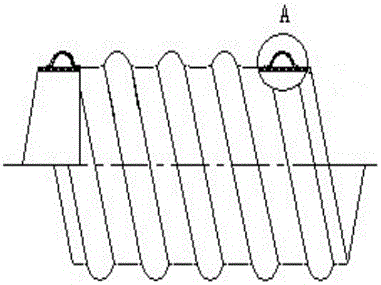

A polyethylene spiral and production process technology, which is applied in the field of steel belt reinforced polyethylene spiral corrugated pipes, can solve the problems of hidden dangers of installation and use, unreasonable parameter setting, difficult pipe forming, etc., so as to reduce the cooling cost and achieve a good cooling effect. , the effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The invention is further described below in conjunction with specific embodiments:

[0028] A production process for a steel strip reinforced polyethylene spiral corrugated pipe, characterized in that it comprises the following steps:

[0029] (1) Inspection of raw materials, including inspection of steel strip, polyethylene resin and bonding resin;

[0030] (2) Plastic-coating the steel strip, and evenly coating the adhesive resin on the surface of the steel strip;

[0031] (3) forming and bending the plastic-coated steel strip in step (2), and the bending shape is V-shaped;

[0032] (4) The extruded sheet of the dried polyethylene resin is wound to form a core layer belt, and the steel belt shaped and bent in step (3) is wound on the core layer belt according to a predetermined pitch. A layer of polyethylene resin is covered on the steel belt to form an outer belt, and the core belt and the plastic-coated steel belt, as well as the bonding and compounding of the pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation induction time | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com