High-energy-ratio low-internal-resistance cylindrical lithium ion battery

A lithium-ion battery, low internal resistance technology, applied in the direction of cylindrical shell battery/battery, secondary battery, secondary battery manufacturing, etc., can solve the difficulty of foil transfer welding tabs, easy false welding, low production efficiency, Low energy ratio and other issues, to achieve the effect of simple design, taking into account production efficiency and low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

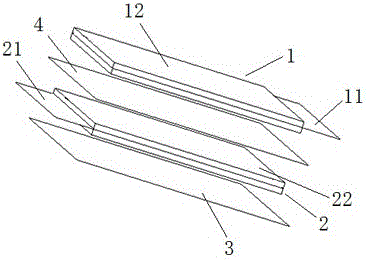

[0013] Such as figure 1 As shown, a cylindrical lithium-ion battery with high energy ratio and low internal resistance in this embodiment includes a cell, and the cell includes a positive electrode sheet 1, a negative electrode sheet 2, an inner diaphragm 3 and an outer diaphragm 4, and the positive electrode sheet 1 and the negative electrode sheet The blank foil areas 11 and 21 used as conductive tabs on the 2 are respectively located at the two ends of the cell, and the inner diaphragm 3, the dressing area 22 of the negative electrode sheet 2, the outer diaphragm 4 and the dressing area 12 of the positive electrode sheet 1 are sequentially attached using a fixed diameter The winding termination method is wound into a battery core. The width of the blank foil area 11 of the positive electrode sheet 1 is 2mm-10mm. The width of the blank foil area 21 of the negative electrode sheet 2 is 2mm-10mm. The two ends of the cell are ultrasonically flattened respectively, so that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com