Preparation method for novel negative electrode material of lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problem of material capacity decline, nano-particles that are easy to agglomerate and grow, easy to break and pulverize, etc. problem, to achieve the effect of maintaining stability, alleviating huge volume changes, and controlling size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

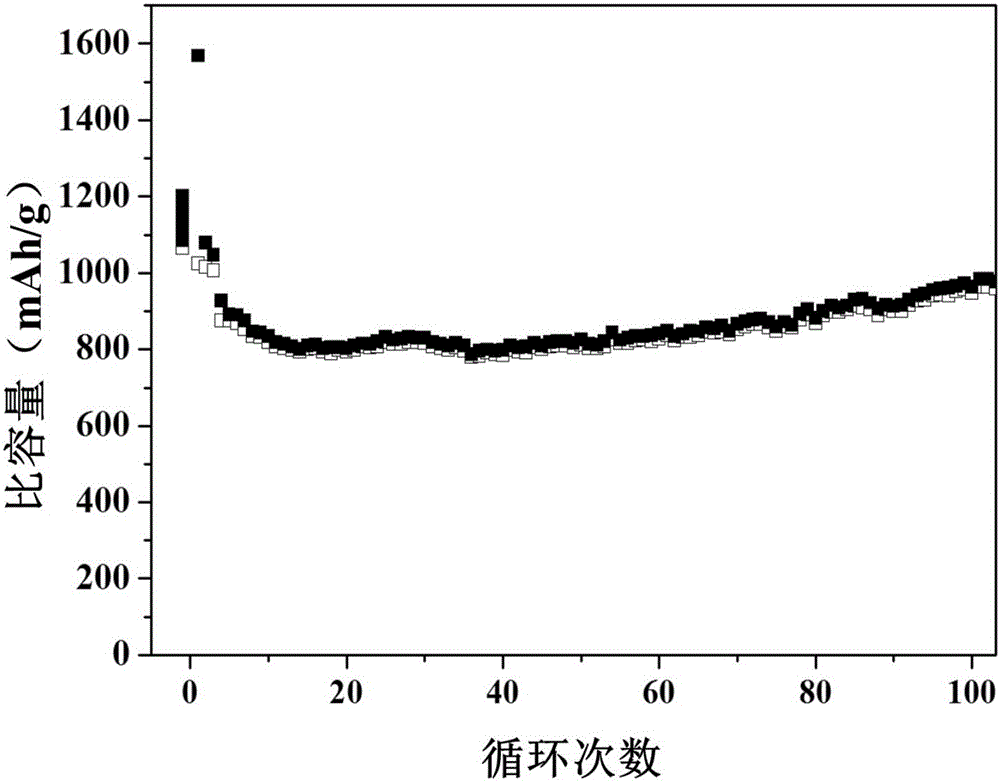

[0023] A preparation method of a novel lithium-ion battery negative electrode material, taking 0.05g of SnCl 4 ·5H 2 O was dissolved in 10ml of acetone-water mixed system, in which the volume ratio of acetone and water was 1:10, and stirred until SnCl 4 ·5H 2 After the O is completely dissolved, add 0.3g of urea and 0.6g of polyvinylpyrrolidone (PVP), stir for 2 hours, add 0.03g of expanded graphite, then transfer the solution into a 100ml hydrothermal reaction kettle, and place it at 110°C for 4 hours of hydrothermal synthesis , after the reaction kettle was naturally cooled to room temperature, the obtained product was suction filtered, washed, dried, and calcined in an inert gas atmosphere at 600°C for 3h to obtain nano-SnO 2 / C Composite. The sample was observed by transmission electron microscopy and found that SnO 2 The size of nanoparticles is less than 10nm, and they are uniformly dispersed on the graphite carrier, such as figure 1 shown. The sample has been test...

Embodiment 2

[0025] A preparation method of a novel lithium-ion battery negative electrode material, taking 0.3g of SnCl 2 2H 2 O was dissolved in 50ml of acetone-water mixed system, wherein the volume ratio of acetone and water ranged from 10:3, stirred until SnCl 2 2H 2 After O is completely dissolved, add 1.5g of urea and 1.4g of polyvinylpyrrolidone (PVP), stir for 5 hours, add 0.1g of expanded graphite, then transfer the solution into a 100ml hydrothermal reaction kettle, and place it at 130°C for 2 hours of hydrothermal synthesis , after the reaction kettle was naturally cooled to room temperature, the obtained product was suction filtered, washed, dried, and calcined in an inert gas atmosphere at 600°C for 3h to obtain nano-SnO 2 / C Composite. The sample has been tested for charge and discharge performance, and the capacity after 100 cycles is 879mAh / g.

Embodiment 3

[0027] A preparation method of a novel lithium-ion battery negative electrode material, taking 0.5g of SnCl 4 ·5H 2 O is dissolved in 80ml of acetone-water mixed system, wherein the volume ratio of acetone and water is in the range of 10:1, and stirred until SnCl 4 ·5H 2 After O is completely dissolved, add 3.5g of urea and 2.5g of polyvinylpyrrolidone (PVP), stir for 5 hours, add 0.2g of expanded graphite, then transfer the solution into a 100ml hydrothermal reaction kettle, and place it at 90°C for 8 hours of hydrothermal synthesis , after the reaction kettle was naturally cooled to room temperature, the obtained product was suction filtered, washed, dried, and calcined in an inert gas atmosphere at 600°C for 3h to obtain nano-SnO 2 / C Composite. The sample has been tested for charge and discharge performance, and the capacity is 665mAh / g after 100 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com