A kind of nickel cobalt aluminum oxide and preparation method thereof

An oxide, nickel-cobalt-aluminum technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as incomplete precipitation of aluminum ions, and achieve the effects of good consistency, high cycle performance, and high charge-discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

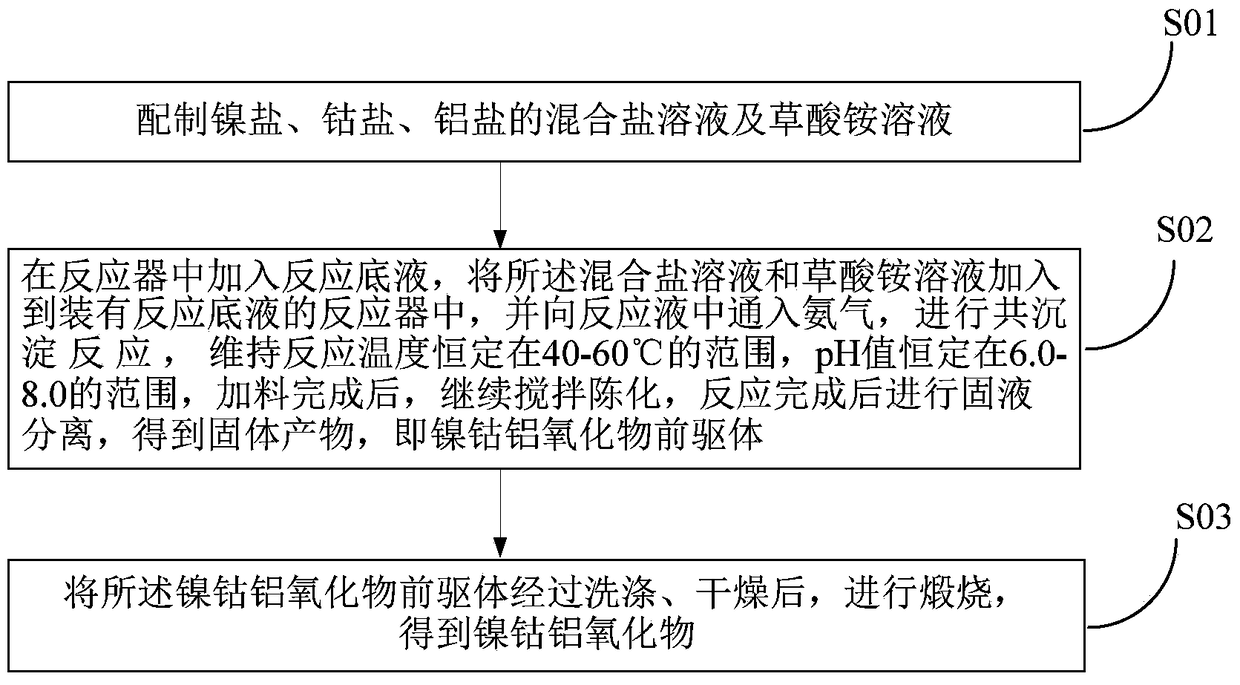

[0046] Please refer to figure 1 , figure 1 It is a flow chart of the preparation method of nickel-cobalt-aluminum oxide in the present invention, comprising the following steps:

[0047] S01, preparing a mixed salt solution of nickel salt, cobalt salt, aluminum salt and ammonium oxalate solution;

[0048] S02. Add the reaction bottom liquid into the reactor, add the mixed salt solution and the ammonium oxalate solution into the reactor equipped with the reaction bottom liquid, and feed ammonia gas into the reaction liquid to carry out coprecipitation reaction and maintain the reaction The temperature is kept constant in the range of 40-60°C, and the pH value is kept constant in the range of 6.0-8.0. After the feeding is completed, continue to stir and age. After the reaction is completed, the solid-liquid separation is carried out to obtain a solid product, that is, the nickel-cobalt-aluminum oxide precursor;

[0049] S03. After the nickel-cobalt-aluminum oxide precursor is ...

Embodiment 1

[0051] A preparation method of nickel cobalt aluminum oxide, comprising the following steps:

[0052] (1) Weigh nickel chloride, cobalt chloride, and aluminum chloride crystals respectively at a molar ratio of 80:15:5, dissolve in water and mix uniformly to obtain a mixed salt solution of nickel, cobalt and aluminum, and the volume of the mixed salt solution is 20L , the total concentration of nickel ion, cobalt ion, aluminum ion in the mixed salt solution is 80g / L, and preparation concentration is the ammonium oxalate solution of 60g / L;

[0053] (2) Add 3L of pure water to a reaction kettle with a volume of 50L, add ammonium oxalate, make the concentration of ammonium oxalate 5g / L, raise the temperature to 40°C, and then mix the nickel-cobalt-aluminum mixture under stirring conditions Add salt solution and 60g / L ammonium oxalate solution into the reaction kettle, and pass ammonia gas into the reaction solution to carry out co-precipitation reaction. During the feeding process...

Embodiment 2

[0058] A preparation method of nickel cobalt aluminum oxide, comprising the following steps:

[0059] (1) Weigh nickel chloride, cobalt chloride, and aluminum chloride crystals respectively at a molar ratio of 80:15:5, dissolve in water and mix uniformly to obtain a mixed salt solution of nickel, cobalt and aluminum, and the volume of the mixed salt solution is 20L , the total concentration of nickel ion, cobalt ion, aluminum ion in the mixed salt solution is 100g / L, and preparation concentration is the ammonium oxalate solution of 80g / L;

[0060] (2) Add 3L of pure water to a reactor with a volume of 50L, add ammonium oxalate so that the concentration of ammonium oxalate is 10g / L, and the temperature is raised to 50°C, and then the nickel-cobalt-aluminum Add the mixed salt solution and 80g / L ammonium oxalate solution into the reaction kettle, and pass ammonia gas into the reaction solution to carry out coprecipitation reaction. During the feeding process, the pH value is main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com