Treatment device for tritium gas and tritiated water

A treatment device, a technology for tritiated water, applied in radioactive purification, nuclear engineering and other directions, can solve the problems of operator and environmental safety hazards, high tritium content in waste gas, and many wastes, etc., to improve adsorption efficiency and catalyst life. Risk of exposure, reduction of toxic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

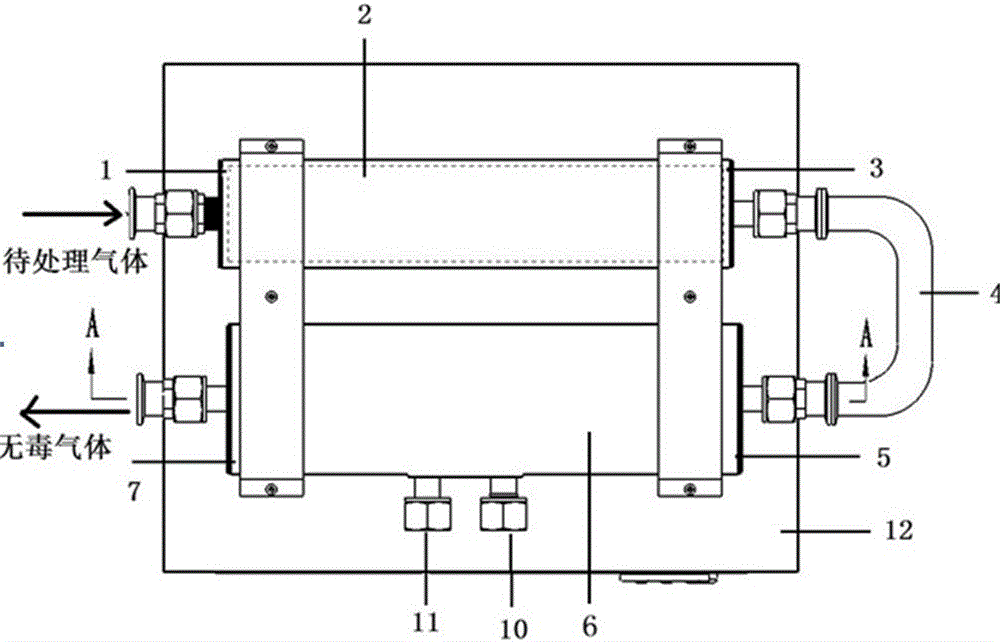

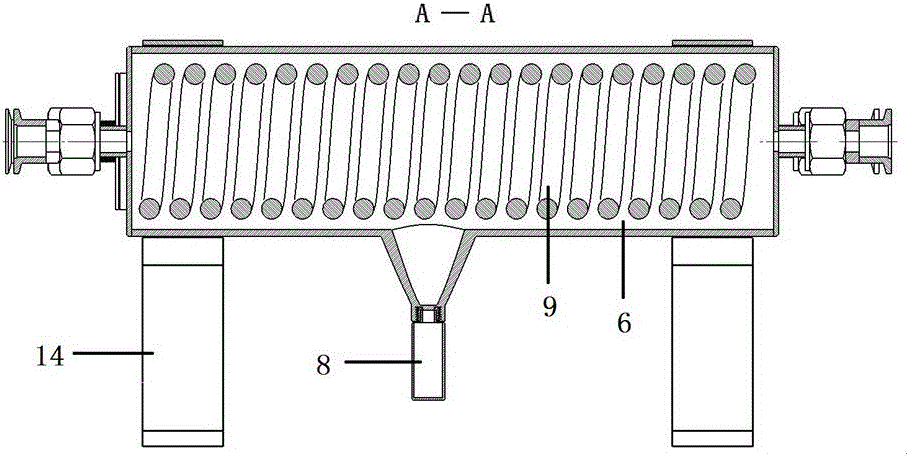

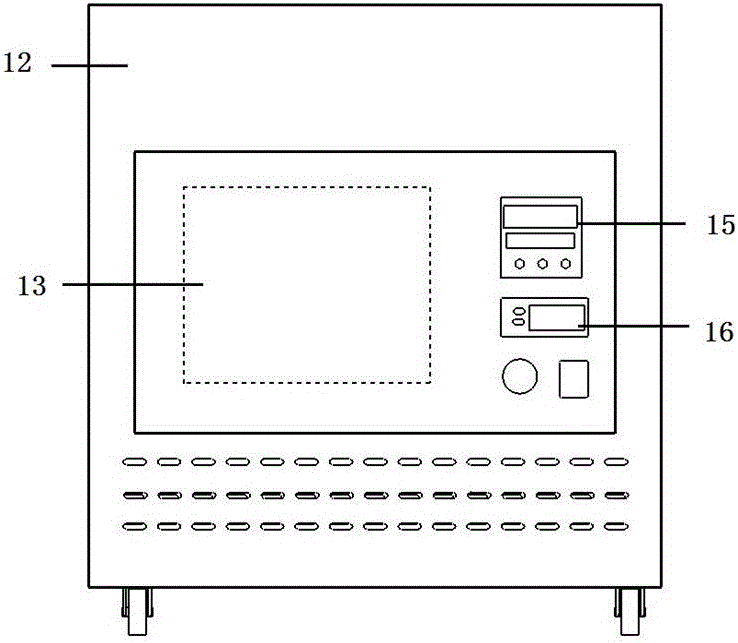

[0019] The device of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as Figure 1~Figure 3 As shown, the treatment device for tritium gas and tritiated water of the present invention includes a total air inlet 1, a cylinder body 2, a cylinder gas outlet 3, a pipeline 4, a convection chamber air inlet 5, a convection chamber 6, and a total gas outlet 7. Tritiated water collection chamber 8, condensation conduit 9, condensation pipe inlet 10, condensation pipe outlet 11, double compensation forced cooling system 13, fixed bracket 14, refrigeration box 12, temperature control panel 15, temperature display Panel 16.

[0021] The total air inlet 1, the cylinder body 2 and the cylinder gas outlet 3 are sequentially connected to form a tritium gas catalytic oxidation studio; the cylinder body 2 is loaded with a honeycomb hydrophobic tritium gas oxidation catalyst; the air inlet 5 of the convection chamber and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com