Method for optioning aroma component in natural moss perfume spice

A technology of aromatizing ingredients and fragrance, which is applied in the field of selection of aromatizing ingredients in natural moss fragrance, can solve the problems of rare aromatizing ingredients, research reports, and no selection method of aromatizing ingredients, so as to achieve easy popularization and use, Easy to operate, accurate effect of important aroma components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

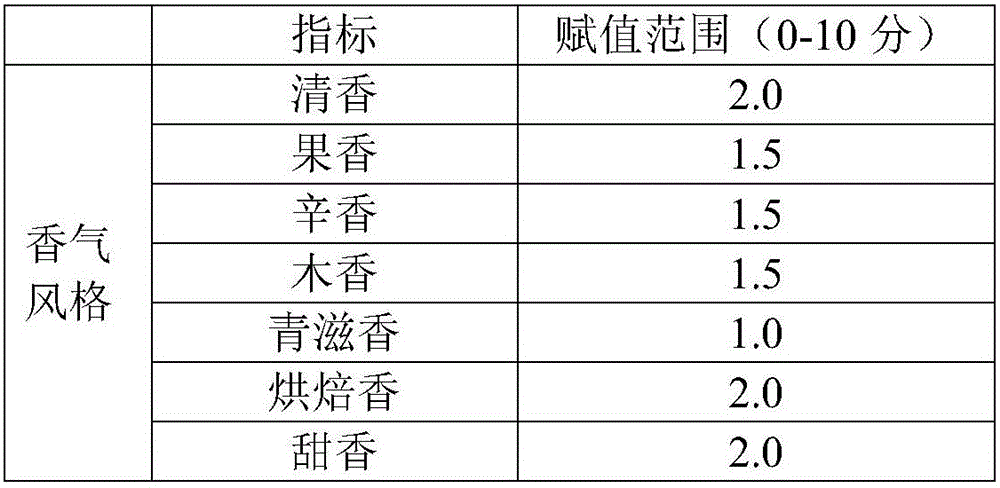

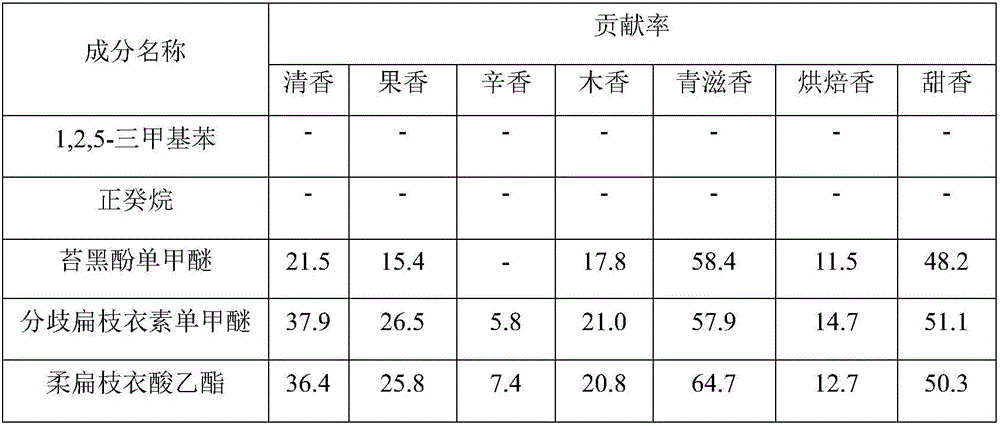

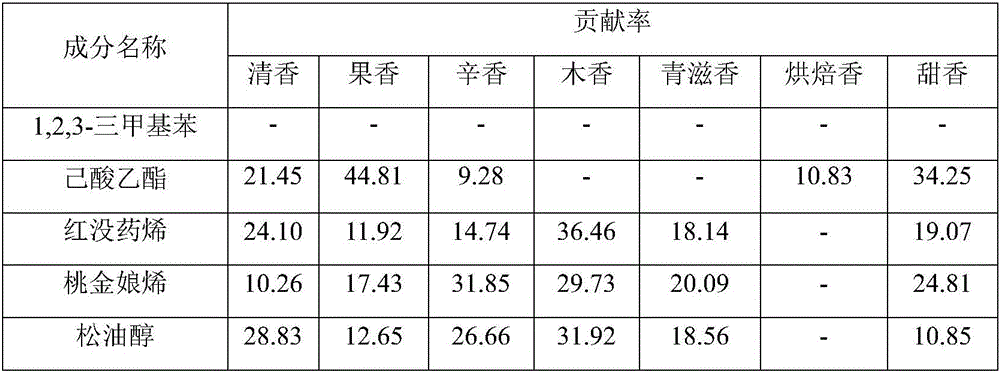

[0028] A method for selecting important aroma components in natural moss fragrance spices, comprising the following steps:

[0029] Fractional separation of raw materials: Weigh 15g of oak moss extract, add 75g of ethanol to it, stir vigorously to disperse, pour the uniformly dispersed solution into the feed liquid bottle of the wiped-film molecular distillation apparatus, turn on the cooling circulating water, Set the temperature of the first-stage and second-stage condensed water to 2°C, the third stage uses liquid nitrogen to condense, the feeding rate is 2ml / min, and the remaining parameters of the instrument are: distillation temperature 50°C, 60°C, 70°C, 80°C ℃, 90℃, the rotating speed of the wiper is 50r / min, 100r / min, 150r / min, 200r / min, 250r / min, the absolute pressure is 0.1Pa, 0.5Pa, 1Pa, 1.5Pa, 2.0Pa, using L 25 (5 6 ) Orthogonal Experimental Design Table to carry out 25 experiments, correspondingly collected 25 first-level, second-level and third-level fractions. ...

Embodiment 2

[0042] The condition and step of embodiment 2 are basically the same as embodiment 1, and the difference between embodiment 2 and embodiment 1 is that the raw material of oakmoss extract is replaced with tree moss absolute. Moss absolute oil is directly graded and separated by molecular distillation equipment.

[0043] The tertiary fraction under each separation condition was uniformly injected into cigarettes at 1% relative to the mass of shredded tobacco using a flavoring injection machine, and the used cigarettes were blank leaf groups without flavoring.

[0044] Organize 20 judges with industry qualifications to evaluate the fragrance profile. After this grade of fraction is added, compared with the control cigarette, the smoke concentration is increased, the aroma of the cigarette is harmonious, and the mouthfeel has no defect. In the front part of the smoke, the sweetness and aroma are improved, and the smoke becomes refined, firm, and sweet with tree moss.

[0045] Wi...

Embodiment 3

[0050] The conditions and steps of embodiment 2 are basically the same as in embodiment 1, and the difference between embodiment 2 and embodiment 1 is that the raw material of oakmoss extract is replaced with tree moss extract. The parameters of the molecular distillation instrument are: distillation temperature 60°C, 80°C, 90°C, 100°C, 1200°C, speed of wiper 100r / min, 150r / min, 200r / min, 250r / min, 300r / min, absolute pressure 5Pa, 10Pa, 20Pa, 30Pa, 50Pa, use L 25 (5 6 ) Orthogonal experimental design table to carry out 25 experiments.

[0051] The second-stage fraction under each separation condition was uniformly injected into cigarettes at a rate of 0.5% relative to the mass of cut tobacco by using a flavoring injection machine, and the used cigarettes were blank leaf groups without flavoring.

[0052] Organize 20 judges with industry qualifications to evaluate the fragrance profile. After this grade of fraction is added, compared with the control cigarette, the smoke is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com