A pile foundation manufacturing device for model testing

A technology for making devices and model tests, which is applied in the preparation of test samples, measuring devices, and using stable tension/pressure to test the strength of materials, etc. layout and other issues to achieve the effect of efficient painting work and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] Embodiment: Below in conjunction with accompanying drawing, the present invention will be further described. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

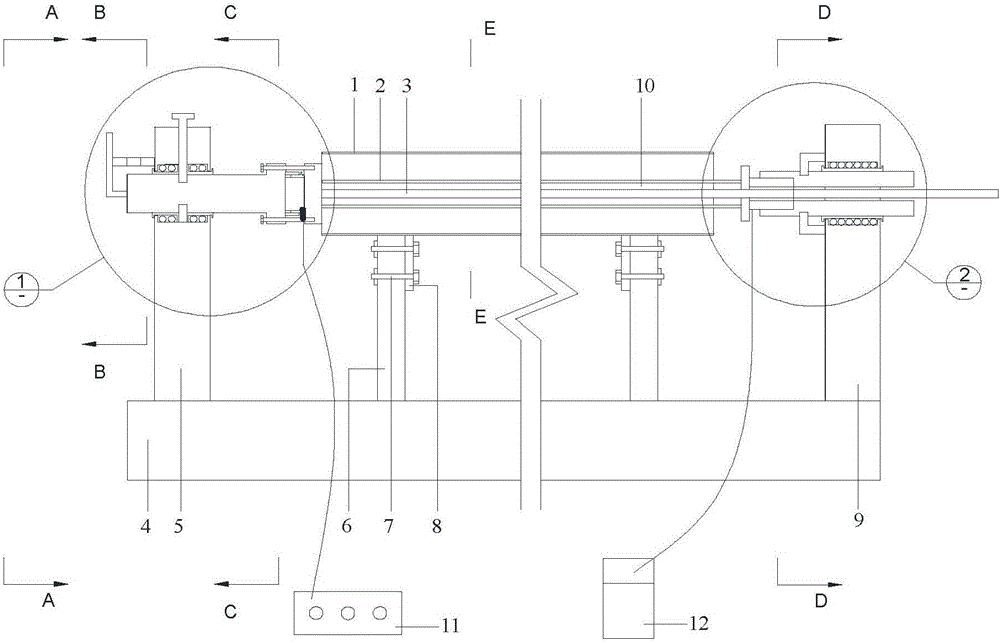

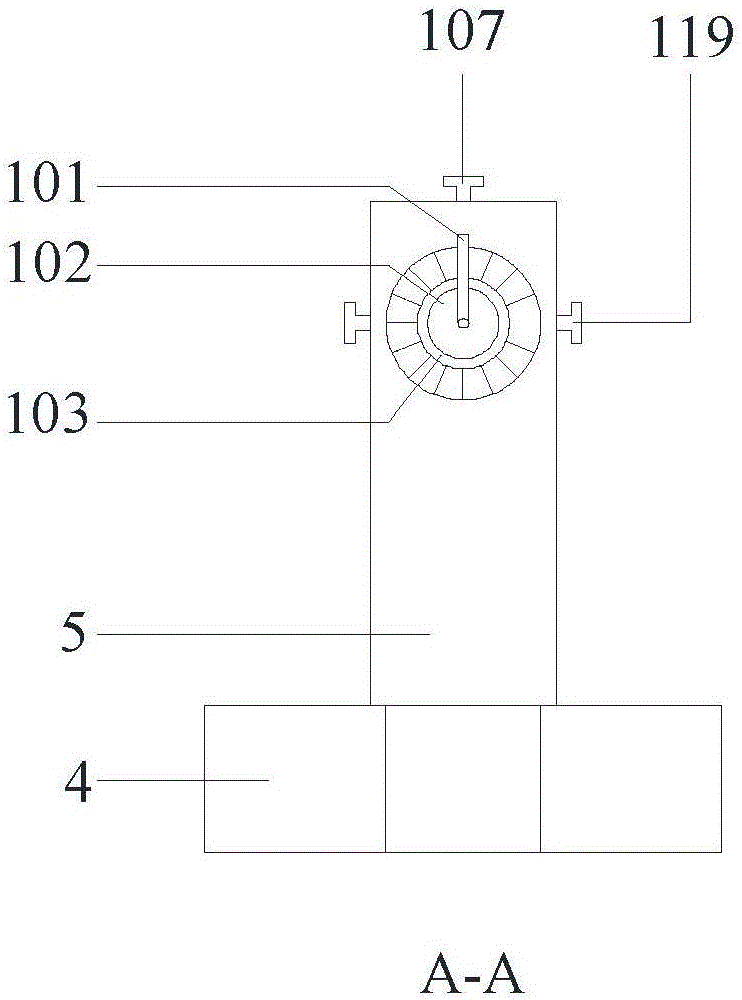

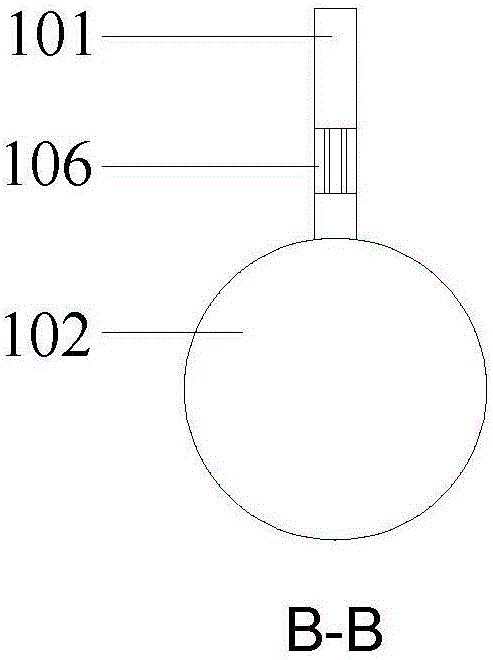

[0042] Such as Figure 1-8 As shown, a pile foundation manufacturing device and method for model tests in this embodiment includes: a sleeve 1, a model pile 2, a central shaft 3, a base 4, a locking support arm 5, an inner support arm 6, a sleeve Barrel bolt 7, fixed plate 8, reaction support arm 9, liner 10, collector 11, hydraulic pump 12, rocker arm 101, locking section 102, locking section liner 103, steel ball 104, pressure sensor wire 105, scale 106 , Top locking bolt 107, longitudinal locking bolt 108, outer retaining wall 109, inner retaining wall 110, pressure sensor 111, backing plate 112, hydraulic pipe 113, limit plate 114, hydraulic loader 115, reaction support 116, reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com