Flexible exhaust connecting device

A connection device and a flexible technology, applied in the field of flexible exhaust connection devices, can solve the problems of easy wear of exhaust pipes and exhaust elbows, increased connection stress of exhaust devices, and increased test tooling costs, etc., to achieve improved dynamics The effect of adjusting the range, reducing mutual wear, and avoiding test accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

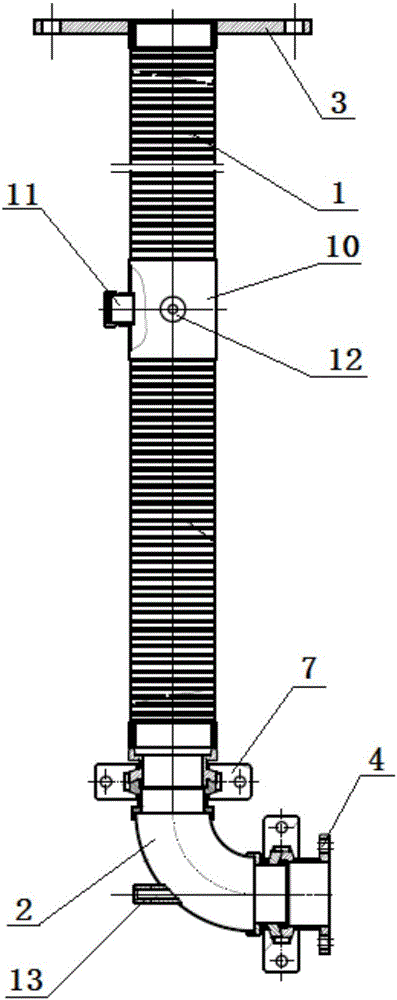

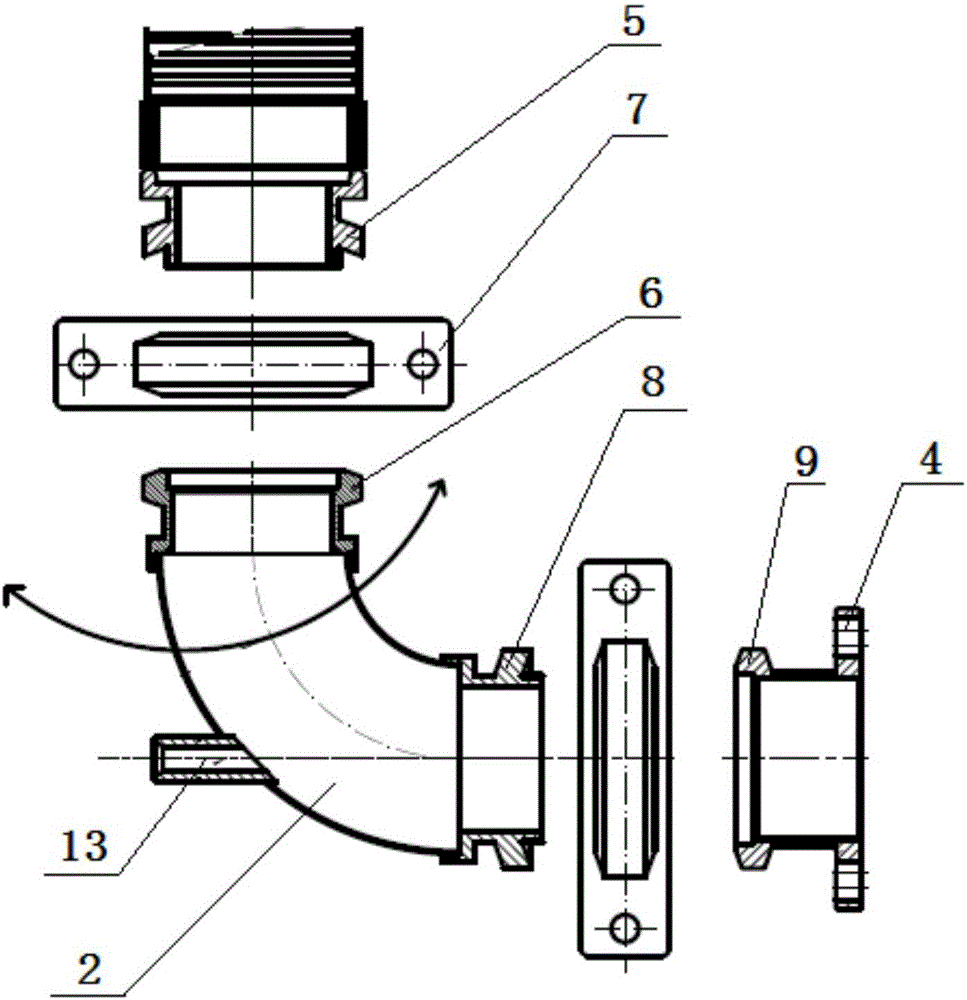

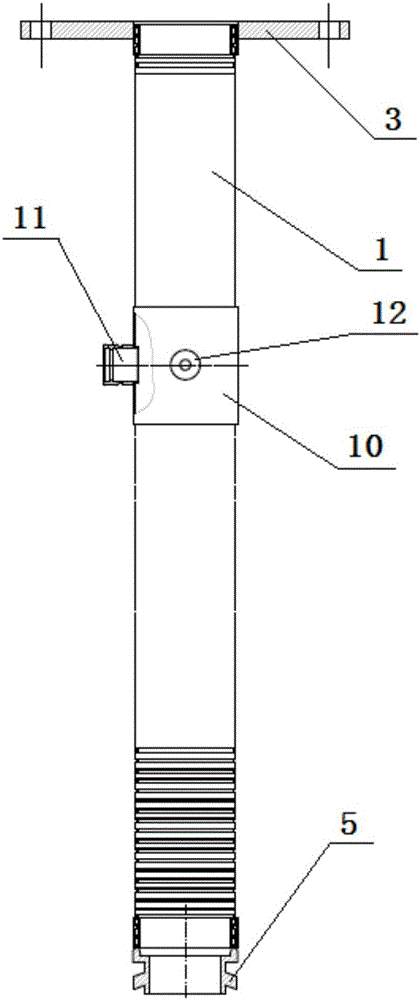

[0029] refer to Figure 1-8 , a flexible exhaust connection device of the present invention includes an axially telescopic and bendable flexible pipe body 1 connected to the bench exhaust main pipe, and the main body of the flexible pipe body 1 adopts a corrugated pipe with foldable corrugated sheets. When installing, stretch the foldable corrugated sheet to both ends of the bellows to extend the exhaust pipe; compress the foldable corrugated sheet to both ends of the bellows to compress the exhaust pipe; stretch the folded corrugated sheet to one side of the connection position and compress the other The generated displacement difference can make the bellows bend to the direction of compression; it can realize stretching and elongation at any position of the exhaust connection device as a whole and change the angle, and the dynamic adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com