Propellant container mechanical environment test safety protection method

A mechanical environment and safety protection technology, applied in the testing of machines/structural components, instruments, vibration testing, etc., can solve problems such as container leakage, personnel and equipment threats, propellant leakage, etc., to achieve safety risks and accurate assessment The effect of the result

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

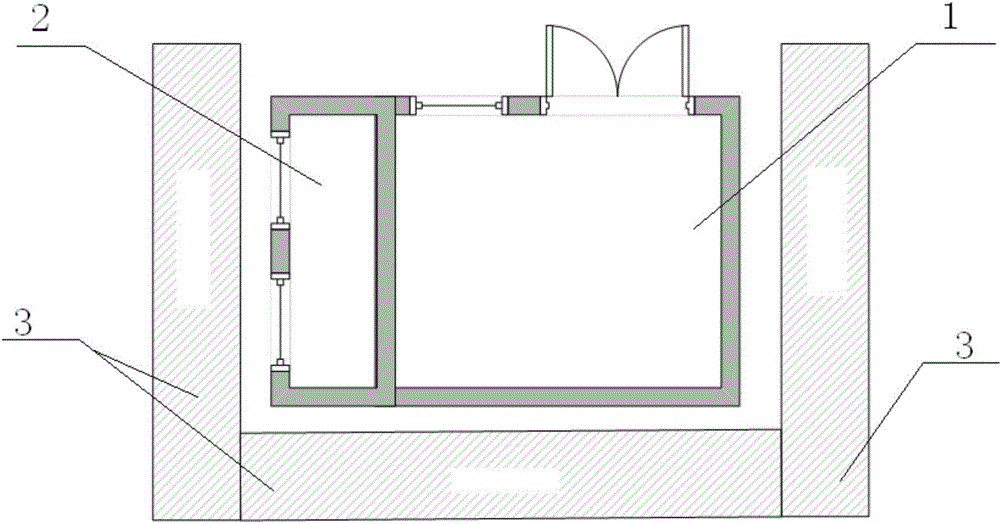

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention is described in further detail below in conjunction with specific embodiments:

[0044] A safety protection method for a propellant container mechanical environment test, comprising the following steps in sequence:

[0045]Step 1. Test safety risk analysis, test safety risks include liquid propellant leakage risk risk, liquid propellant toxicity risk and liquid propellant contamination risk;

[0046] Step 1.1 Liquid propellant leakage hazard risk analysis,

[0047] The main risk of the mechanical environment test of the propellant container is that the dynamic stress in the mechanical environment test may cause damage to the propellant container, resulting in the leakage of the liquid propellant in the propellant container. There are two cases of liquid propellant leakage: one is that the fuel and oxidant of liquid propellant leak at the same time, and the spontaneous combustion propellant leaks and mixes at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com