Metal rivet nut and machining process thereof

A technology of riveting nuts and processing technology, which is applied in the direction of nuts, connecting components, threaded fasteners, etc., can solve problems such as water leakage, damage to the structure of stainless steel plates, rust spots, etc., achieve good sealing effect, and overcome the destruction of metal intergranular structure , easy-to-implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

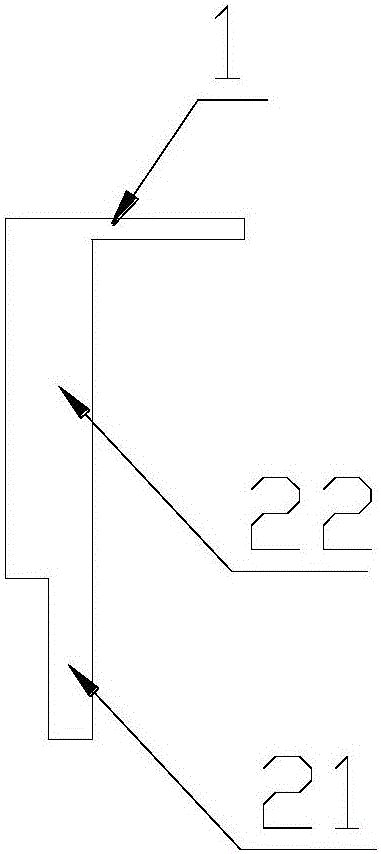

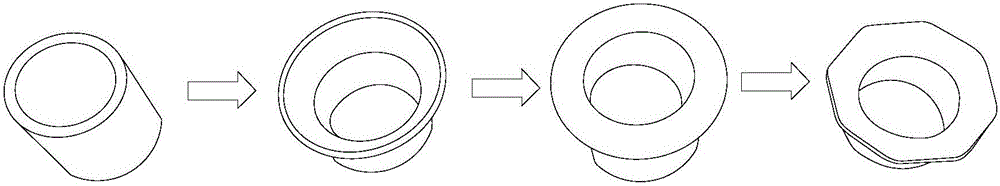

[0020] Such as figure 1 and figure 2 As shown, the metal riveting nut of the present invention has an integrated structure, and its structure includes a cap head 1 and a riveting tube 2 , and the cap head 1 is located at the top of the riveting tube 2 . The riveted pipe 2 comprises a riveted pipe upper layer 22 and a riveted pipe lower layer 21. The riveted pipe upper layer 22 is the end close to the cap head, and the riveted pipe lower layer 21 is the end far away from the cap head. The thickness of the tube wall of the lower tube layer 21 is less than the thickness of the tube wall of the riveted tube upper layer 22, which is convenient for turning over. The cap head 1 is octagonal, and the concentricity between the octagonal cap head and the riveted pipe 2 is high, which is beautiful and does not generate too much waste. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com