Covered-excavation full-top-down construction method of municipal underground engineering

An underground engineering and construction method technology, applied in water conservancy projects, infrastructure engineering, artificial islands, etc., can solve problems such as high cost and investment, impact on road traffic, and long project cycle, so as to save support costs, avoid construction period, The effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

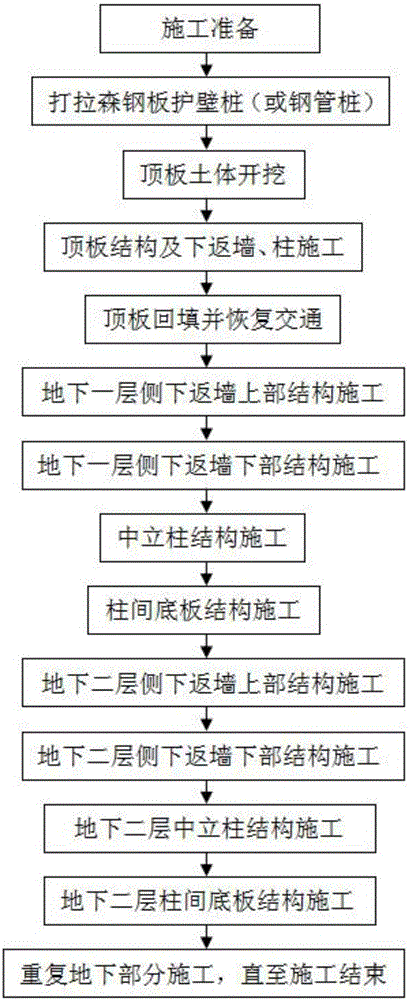

Method used

Image

Examples

Embodiment 1

[0070] Example 1: The middle section of Jiangyou City Monument and the middle section of Jiefang Road combined with public civil air defense project This project is located in Jiangyou City, Sichuan, with a civil air defense construction area of about 29,300 square meters; normal function: underground commercial street and underground pedestrian crossing; wartime function: personnel Concealment and material storage warehouse. Protection category: Class B Resistance level: Level 6. The length of the project is 1171.5 meters, with a basement floor, the basic horizontal span is 7 meters + 6 meters + 7 meters, and the partial is 8 meters x n span (n is an integer from 5 to 7); the longitudinal span is 8 meters; the structural floor height is 5.7 rice.

Embodiment 2

[0071] Example 2: Nanchang Shengli Road Civil Air Defense Combined Civil Defense Project is located on Shengli Road, Donghu District, Nanchang City. It starts from Zhongshan Road in the south and goes to Yangming Road in the north; it starts from Xiangshan Road in the east and ends in Zongmao Road in the west. It is a combined peacetime and wartime project. The total length is about 2030m, and the total construction area of the project is 52696 square meters. It will be implemented in two phases. The specific location is from Shengli Road to Lijia Road (Jiandeguan Road) to Zhongshan Road, the axis number is B63-A2, the total length is about 730m, and the construction area is 27,000m. The foundations of Shengli Road Civil Defense Civil Defense and Warfare Combination Project are buried at depths ranging from 9.5m to 12m. The main structure adopts reinforced concrete beamless floor slabs; the bottom slab is 500mm thick, the roof slab is 450mm thick, and the outer wall and middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com