Reinforcement structure for inclined cracks in main girder web plate of box girder bridge and construction method thereof

A main girder web, reinforcement structure technology, applied in the direction of bridge reinforcement, bridge, bridge maintenance, etc., can solve the problems of difficult to ensure the effect of stress application, difficult to effectively measure the tensile force, unable to replace, etc., to achieve the replacement of external vertical prestress The effect of convenient reinforcement, simple method and convenient reinforcement structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

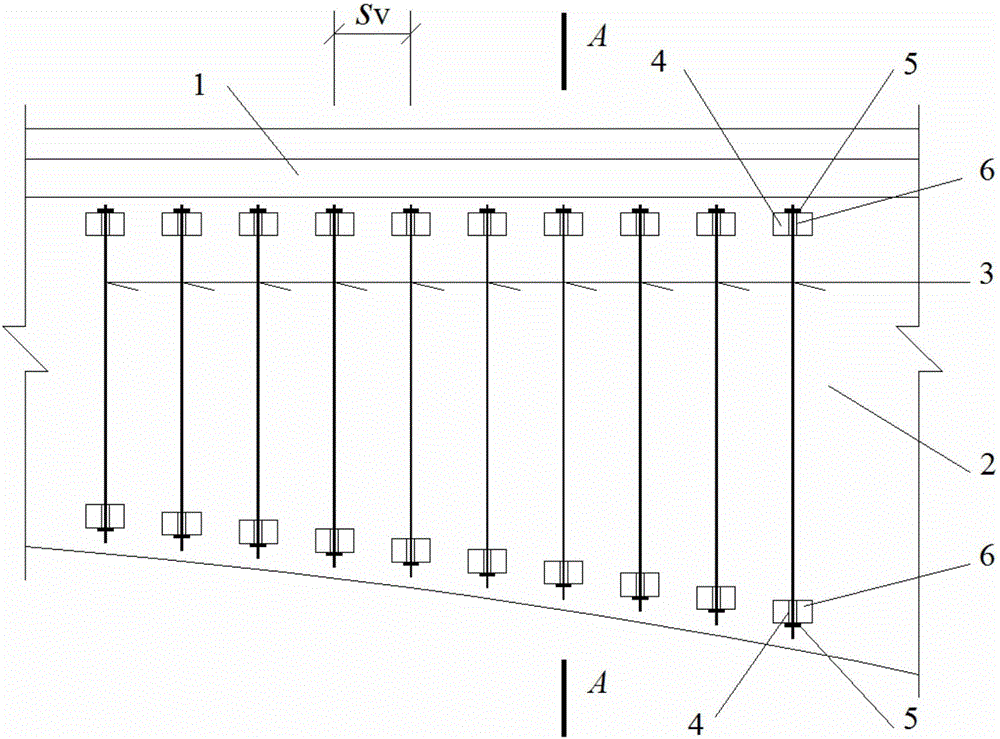

[0042] The present invention will be further described below in conjunction with drawings and embodiments.

[0043] This embodiment is to use the present invention to repair and strengthen a concrete box girder bridge with oblique cracks in the web of the main girder.

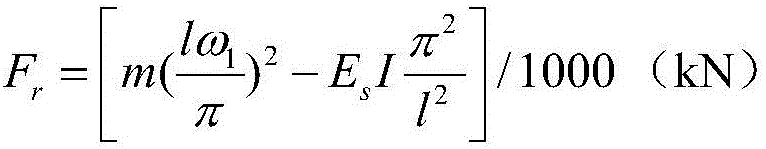

[0044] The box girder bridge is a prestressed concrete continuous rigid frame bridge with a main span of 160m. It is designed according to the fully prestressed concrete structure. The main beam is made of C60 concrete, f tk =2.85MPa; fully prestressed concrete components poured on site: γ=0.4, poured on site. By establishing the finite element model of the bridge structure, the maximum value σ of the main tensile stress of the main girder web section under the short-term effect combination of the box girder bridge is calculated tp = 3.03 MPa.

[0045] One year after the beam bridge was completed and put into operation, it was found that oblique cracks occurred in the main girder web near the 1 / 4 span of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com