Box type high-strength bamboo laminated wood beam and manufacturing method

A glulam, high-strength technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of imperfect bamboo and wood structure design theory, unfavorable standardized production, lack of versatility, etc. Beam bearing efficiency and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method for preparing a box-shaped high-strength bamboo laminated beam, comprising the following steps:

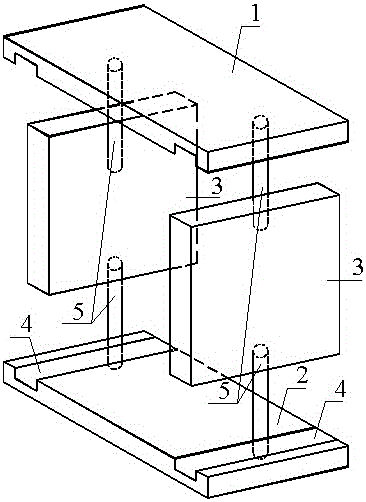

[0027] (1) The high-strength bamboo glulam top plate with A slots 4 at both ends, the high-strength bamboo glulam bottom plate with B slots 4 at both ends, and the high-strength bamboo glulam web 3 respectively pass through A and B slots 4, A and B The low-density bamboo glulam shear-resistant bamboo pins 5 are assembled together. The length and width of the box-shaped high-strength bamboo glulam beams are determined by the design requirements, and the height of the box-shaped high-strength bamboo glulam beams can be determined by the height of the web according to the stress. Adjustment;

[0028] (2) The production of the high-strength bamboo glulam bottom plate and top plate in the box-shaped high-strength bamboo glulam beam includes the following steps:

[0029] 1) Use high-strength bamboo glulam, that is, use raw bamboo with a bamboo age of about 4 years, cut ...

Embodiment

[0047] Box-shaped high-strength bamboo glulam beam, its structure includes high-strength bamboo glulam top plate 1 (with A slots 4 at both ends), high-strength bamboo glulam bottom plate 2 (with B slots 4 at both ends), high-strength bamboo glulam web 3 1. Low-density laminated bamboo lumber shear-resistant bamboo pin 5, wherein the upper part of the high-strength bamboo glulam top plate 1 and the high-strength bamboo glulam web 3 are connected by A card slot 4 and A low-density bamboo glulam shear-resistant bamboo pin 5, and the high-strength bamboo glulam The lower part of the glulam bottom plate 2 and the high-strength bamboo glulam web 3 is connected through the B card slot 4 and the B low-density bamboo glulam shear-resistant bamboo pin 5 .

[0048] The high-strength bamboo glulam refers to the tensile strength along the grain not less than 100MPa, the compressive strength along the grain not less than 50MPa, the modulus of elasticity along the grain not less than 11000MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength along the grain | aaaaa | aaaaa |

| Along the grain compressive strength | aaaaa | aaaaa |

| Modulus of elasticity along the grain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com