Silica gel cloth dipping machine

A silicone cloth and impregnation technology, applied in textiles and papermaking, liquid/gas/steam textile material processing, textile material processing, etc., can solve the problems affecting the performance of the final product, affecting product performance, temperature concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

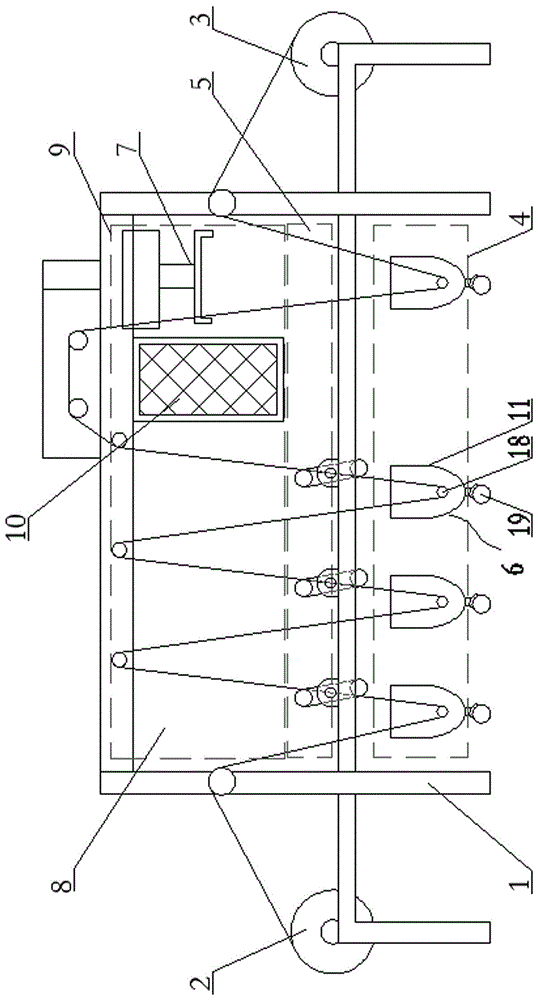

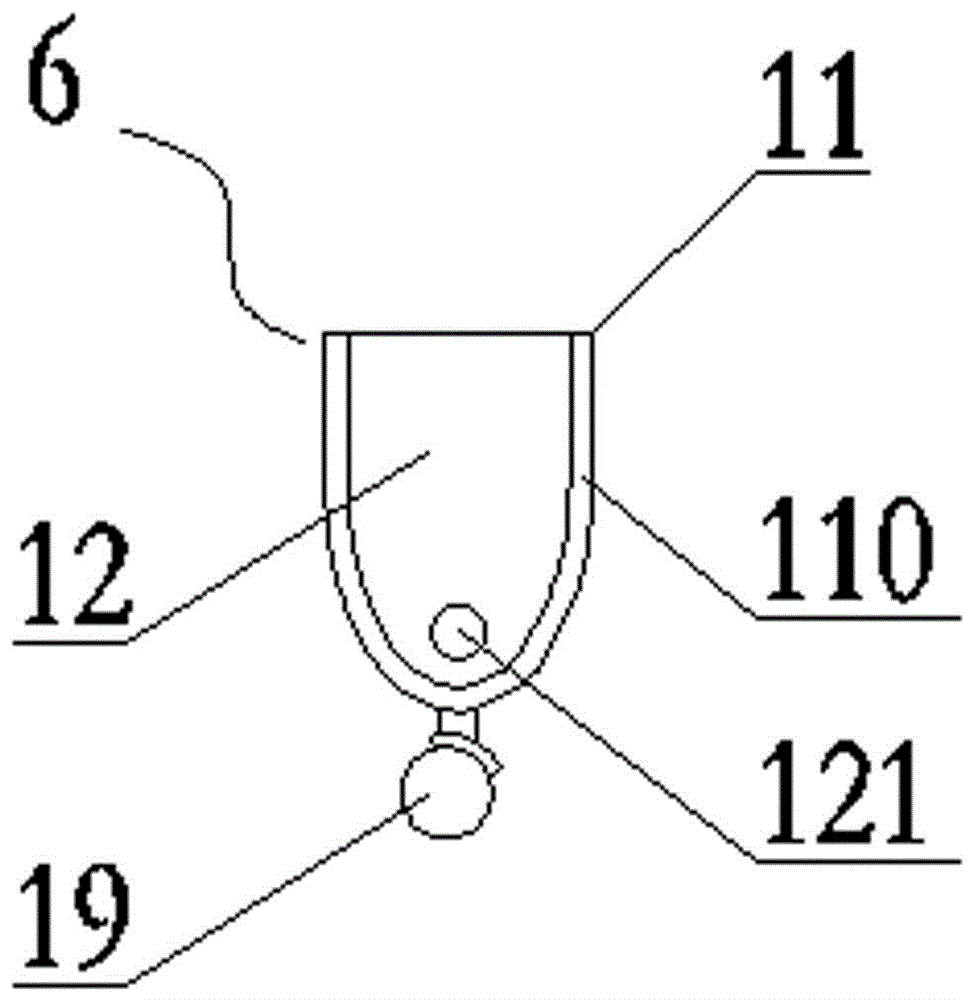

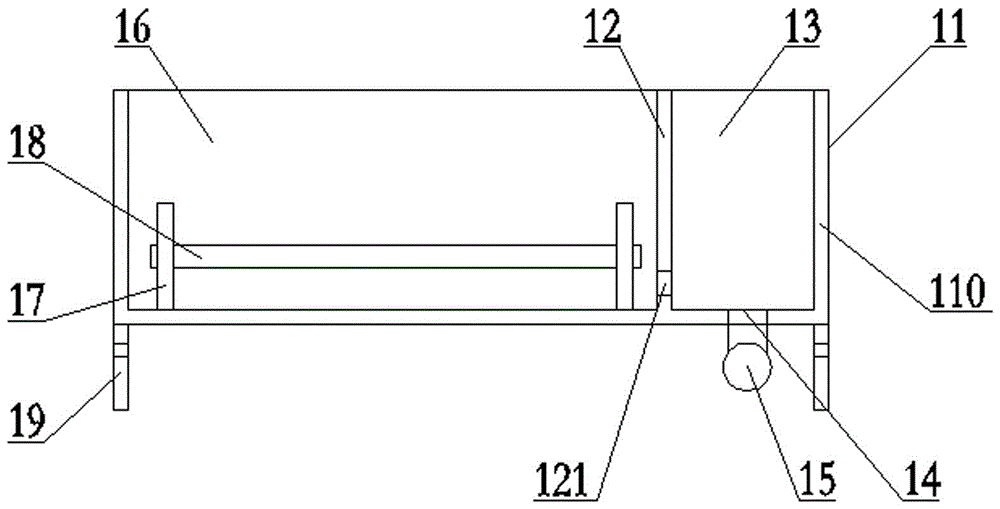

[0012] Further description will be made below in conjunction with drawings and embodiments.

[0013] Figure 1-4 Shown: a silicone cloth dipping machine, including a frame 2, a feeding roller 1 and a receiving roller 3, the feeding roller 1 and the receiving roller 3 are respectively arranged at the front end and the rear end of the frame 2, inside the frame The lower layer is the dipping area 4, and the upper layer is the drying area. The lower part of the rack in the dipping area is mounted with multiple glue tanks 6 from front to back. The rack in the drying area is equipped with rails, and the rubber slots are slidingly set on the rails for lifting. Rack 7, the rubber tank lifting frame corresponds to the two ends of the rubber tank extending out of the frame, and the middle part of the upper drying area is provided with high and low temperature barriers before and after the barrier 10 to divide the drying into high and low temperature drying areas 8, 9, high The low-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com