Method for making sweet sparkling cider

A cider and sweet type technology, applied in the field of fermentation processing, can solve the problems that cider has not been reported, achieve the effect of natural taste coordination and reduce process operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A brewing method of sweet sparkling cider, comprising the following steps:

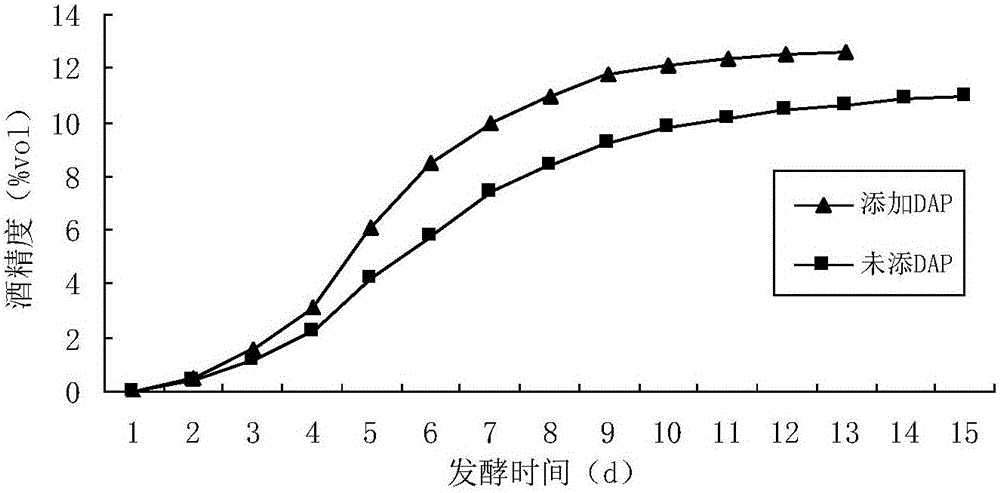

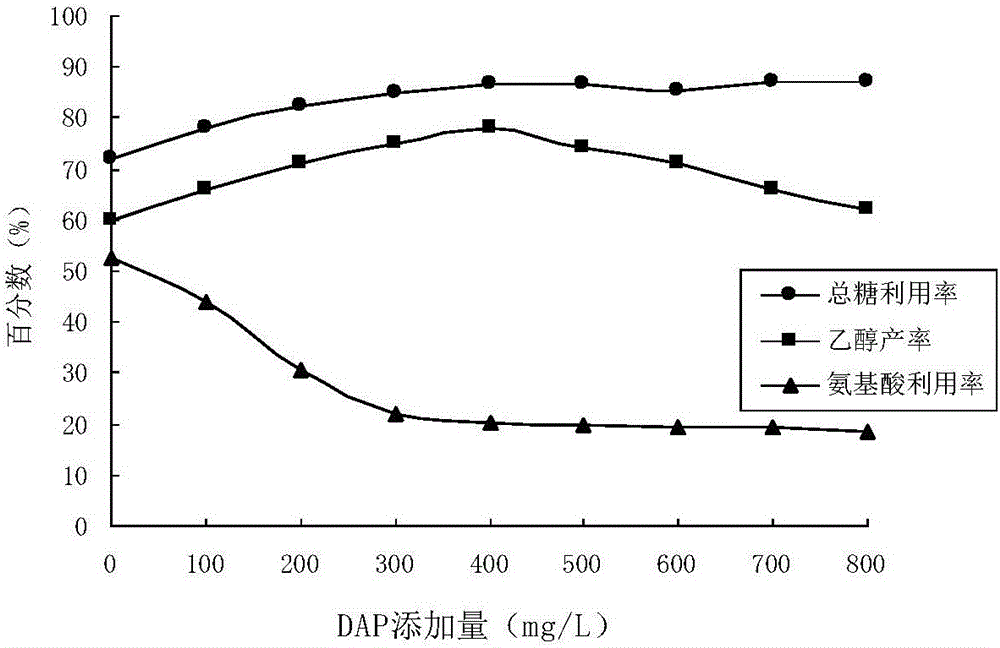

[0037] 1) Boil clean water for 5 minutes to sterilize, cool down to 85°C, add concentrated apple juice with soluble solids ≥ 70°Bx, titratable acid > 0.8%, adjust the sugar content to 15°Bx, according to the amount of 300mg / L Add diammonium phosphate (nitrogen source) to the fermentation broth, stir evenly, and cool down to 20°C to prepare the fermentation broth;

[0038] 2) Yeast activation: Take the fruit wine yeast and add it to the sugar solution at a ratio of 1:20, and activate it for 30 minutes at 30°C. The number of fruit wine yeast is 8 million / mL;

[0039] 3) Main fermentation: After the inoculation is completed, the main fermentation is carried out, and the temperature is controlled at 20°C. When the sugar content drops to 8°Bx, the main fermentation is stopped and the tank is sealed;

[0040]4) Post-fermentation: adjust the pressure of the fermenter to 0.15MPa, keep the fermentatio...

Embodiment 2

[0060] A brewing method of sweet sparkling cider, comprising the following steps:

[0061] 1) Boil clean water for 5 minutes to sterilize, cool down to 88°C, add concentrated apple juice with soluble solids ≥ 70°Bx, titratable acid > 0.8%, adjust the sugar content to 18°Bx, according to the amount of 400mg / L Add diammonium phosphate (nitrogen source) to the fermentation broth, stir evenly, and cool down to 20°C to prepare the fermentation broth;

[0062] 2) Yeast activation: Take the fruit wine yeast and add it to the sugar solution at a ratio of 1:20. Activate it for 25 minutes at 32°C. After the activation, inoculate the activated fruit wine yeast in the fermentation broth. The number of fruit wine yeast is 9 million / mL;

[0063] 3) Main fermentation: After the inoculation is completed, the main fermentation is carried out, and the temperature is controlled at 18°C. When the sugar content drops to 9°Bx, the main fermentation is stopped and the tank is sealed;

[0064] 4) P...

Embodiment 3

[0068] A brewing method of sweet sparkling cider, comprising the following steps:

[0069] 1) Boil clean water for 5 minutes to sterilize, cool down to 90°C, add concentrated apple juice with soluble solids ≥ 70°Bx, titratable acid > 0.8%, adjust the sugar content to 20°Bx, according to the amount of 500mg / L Add diammonium phosphate (nitrogen source) to the fermentation broth, stir evenly, and cool down to 20°C to prepare the fermentation broth;

[0070] 2) Yeast activation: Take fruit wine yeast and add it to the white sugar solution at a ratio of 1:20, and activate it for 20 minutes at 35°C. The number of fruit wine yeast is 10 million / mL;

[0071] 3) Main fermentation: After the inoculation is completed, the main fermentation is carried out, and the temperature is controlled at 22 ° C. When the sugar content drops to 10 ° Bx, the main fermentation is stopped and the exhaust pipe of the fermentation tank is closed;

[0072] 4) Post-fermentation: adjust the pressure of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Total acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com