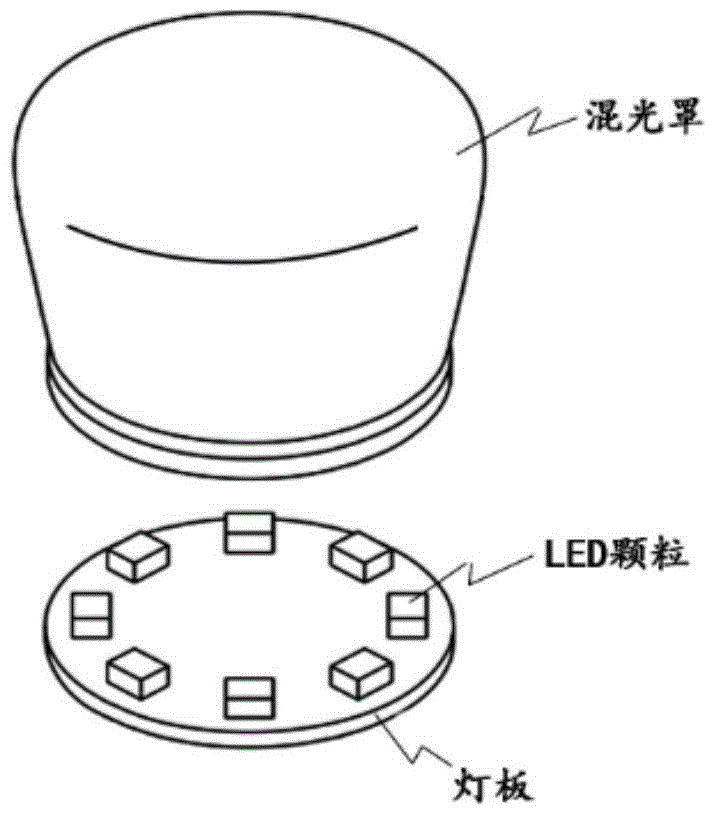

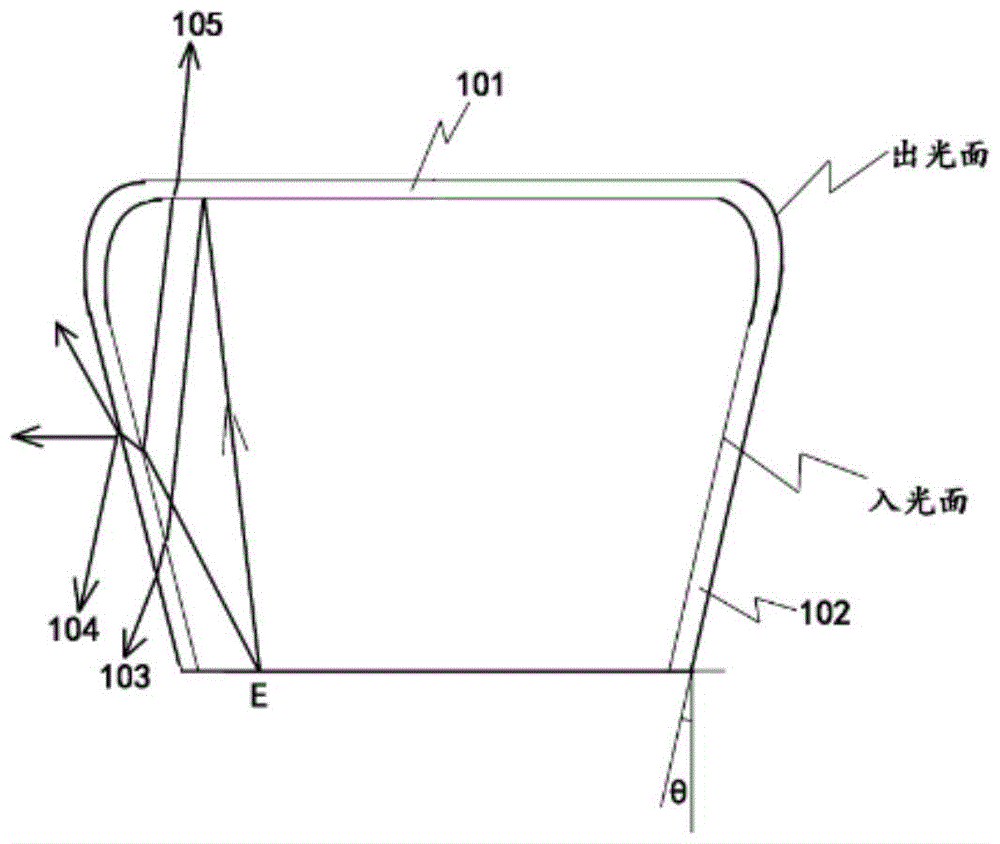

Composite material used for LED light mixing device and LED light mixing device comprising same

A composite material and light mixing device technology, which is applied in the field of composite materials, can solve the problems of increasing light loss, reducing the light output efficiency of LED bulb lamps, and increasing the luminous angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The composite material of the present invention used to manufacture the light mixing mask of the present invention is selected to include polycarbonate with a mass ratio of 90% as a matrix material, and the polycarbonate is doped with: SiO 2 Particles, the particle size of which is between 100nm-50μm, the mass ratio is 5%; and TiO 2 Particles, the particle size of which is between 100nm-250nm, and the mass ratio is 0.0001%. The selected matrix material and particle mixture are uniformly stirred and then put into a twin-screw granulator to make a composite material masterbatch; after the masterbatch is obtained, it is injected into an injection molding machine for injection molding production. In the injection molding process, the mixture with polycarbonate as the base material can be thermally cured to obtain the final composite material.

Embodiment 2

[0069] The composite material of the present invention used to manufacture the light mixing mask of the present invention is selected to include polycarbonate with a mass ratio of 90% as a matrix material, and the polycarbonate is doped with: SiO 2 Particles, the particle size of which is between 100nm-50μm, the mass ratio is 0.0001%; and TiO 2 Particles, the particle size of which is between 100nm-250nm, and the mass ratio is 5%. The selected matrix material and particle mixture are uniformly stirred and then put into a twin-screw granulator to make a composite material masterbatch; after the masterbatch is obtained, it is injected into an injection molding machine for injection molding production. In the injection molding process, the mixture with polycarbonate as the base material can be thermally cured to obtain the final composite material.

Embodiment 3

[0071] The composite material of the present invention used to manufacture the light mixing cover of the present invention is selected to include polycarbonate or polystyrene with a mass ratio of 90% as a matrix material, and the polycarbonate or polystyrene is doped with: SiO 2 particles, the particle size of which is 700nm, and the mass ratio is 0.5%; and TiO 2 Particles, the particle diameter of which is 200nm, and the mass ratio is 0.001%. The mixture of the selected matrix material and particles is uniformly stirred and then put into a twin-screw granulator to make a composite material masterbatch; after obtaining the masterbatch, it is injected into an injection molding machine for injection molding production. In the injection molding process, the mixture with polycarbonate as the base material can be thermally cured to obtain the final composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| beam angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com