Preparation method of light scattering mould plastic based on SiO2/PMMA

A light scattering and molding compound technology, applied in the field of optical functional materials, can solve problems such as low cost, uneven products, dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

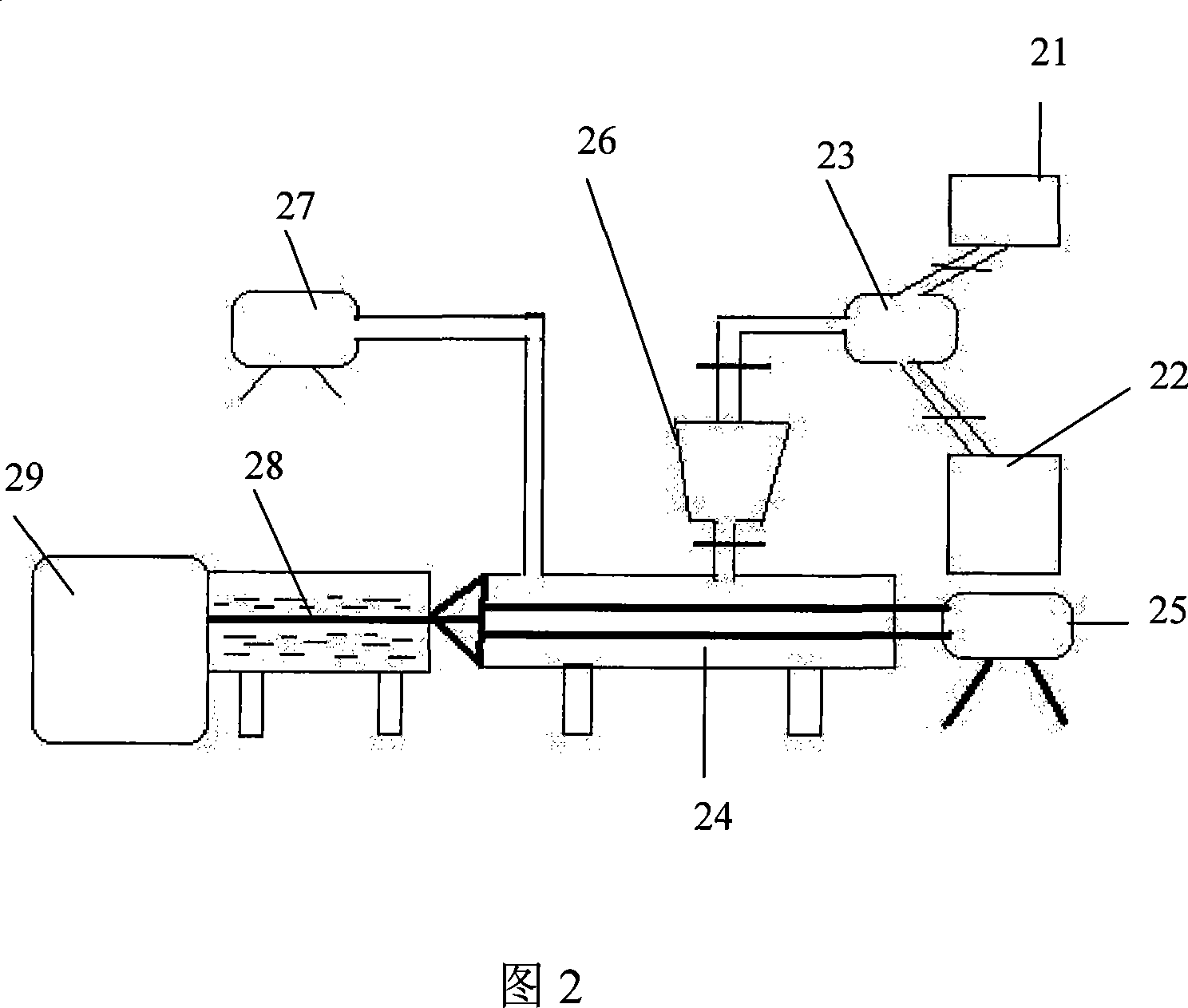

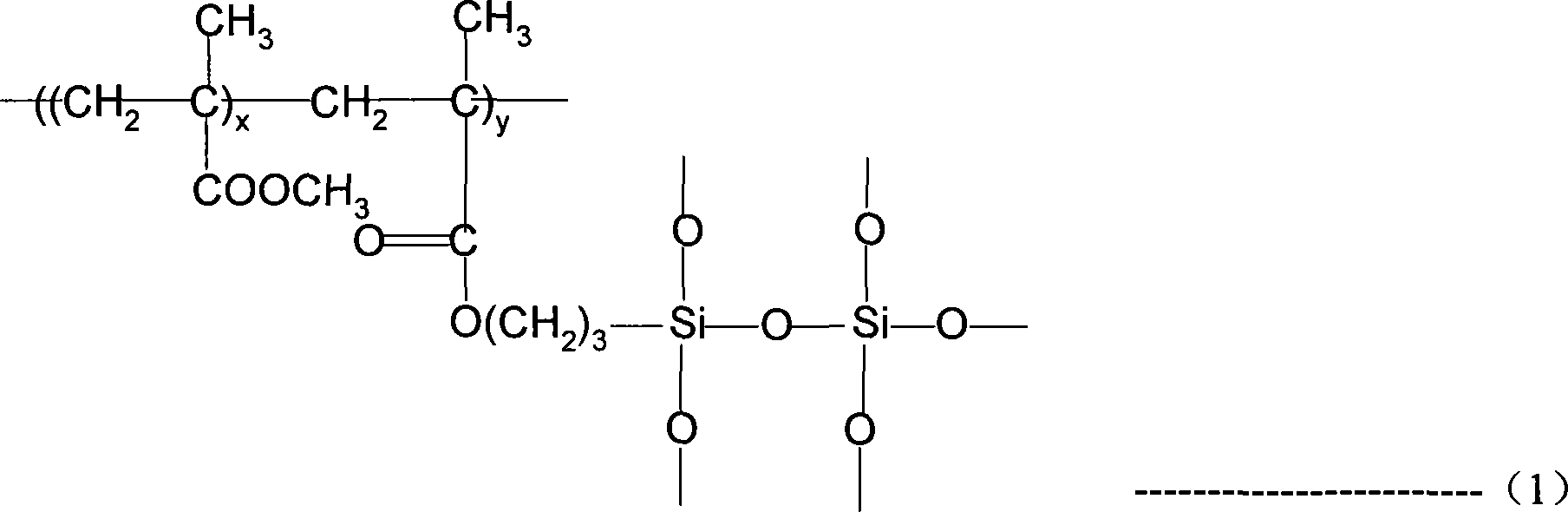

[0050] Step 1: Synthesis of Light Scattering Composite Material:

[0051] Add 200 grams of tetraethoxysilane (TEOS), 200 grams of MSMA, 200 grams of PMMA, and 400 grams of MMA into a 1500-ml round-bottomed flask, add 0.8 grams of AIBN as an initiator, and add 0.8 grams of n-butyl mercaptan as Chain transfer agent, obtain transparent reaction solution after fully stirring and dissolving, and this reaction solution is injected in the separating funnel of 1500 milliliters.

[0052] Add 3000 milliliters of distilled water in the three-necked flask of 5 liters, adopt oil bath to heat the temperature of distilled water to 80 degrees Celsius, slowly add reaction solution in distilled water, and keep stirring to the whole system, stirring speed is kept on 500 revolutions per minute, keeps The temperature of the whole system is 80 degrees Celsius. After adding the reaction solution, keep the system temperature and stirring speed constant. After 6 hours, stop heating and keep stirring u...

Embodiment 2

[0058] Step 1: Synthesis of Light Scattering Composite Material:

[0059] Add 20 grams of tetramethoxysilane (TMOS), 100 grams of MSMA, 100 grams of PMMA, and 400 MMA into a 1000 ml round bottom flask, add 0.5 grams of BPO as an initiator, and add 0.2 grams of dodecyl mercaptan as a chain Transfer agent, obtain transparent reaction solution after fully stirring and dissolving, and inject this reaction solution in the separating funnel of 800 milliliters.

[0060] Add 3000 milliliters of distilled water in the three-necked flask of 5 liters, adopt oil bath to heat the temperature of distilled water to 75 degrees centigrade, slowly add reaction solution in distilled water, and keep stirring to whole system, stirring speed is kept on 650 revolutions per minute, keeps The temperature of the whole system is 75 degrees centigrade. After the addition of the reaction solution, keep the system temperature and stirring speed constant, stop heating after 3 hours, and keep stirring until ...

Embodiment 3

[0066] Step 1: Synthesis of Light Scattering Composite Material:

[0067] Add 150 grams of ethoxytrimethoxysilane, 10 grams of MSMA, 100 grams of PMMA, and 550 grams of MMA into a 1000-ml round-bottomed flask, add 0.6 grams of BPO as an initiator, and add 0.8 grams of dodecyl mercaptan as a The chain transfer agent was fully stirred and dissolved to obtain a transparent reaction solution, and this reaction solution was injected into a 1000 ml separatory funnel.

[0068] Add 3000 milliliters of distilled water in the three-necked flask of 5 liters, adopt oil bath to heat the temperature of distilled water to 65 degrees Celsius, slowly add reaction solution in distilled water, and keep stirring to the whole system, stirring speed is kept on 750 revolutions per minute, keeps The temperature of the whole system is 65 degrees Celsius. After adding the reaction solution, keep the system temperature and stirring speed constant. After 4 hours, stop heating and keep stirring until the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com