Preparation method and application of viscosity-reducing polycarboxylate water reducer

The technology of viscous polycarboxylic acid and water reducing agent is applied in the field of concrete admixtures, which can solve the problems of large pollution in the production process, high raw material cost and high production cost, and achieve the effects of low cost, simple construction process and small pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

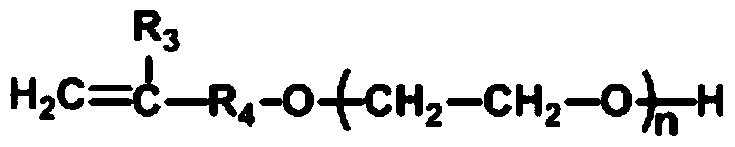

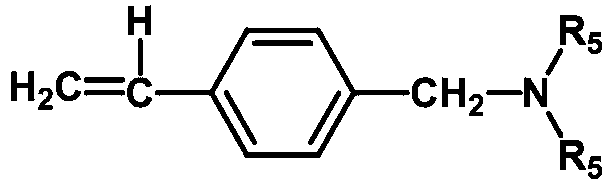

[0046] In this embodiment, the molar ratio of the unsaturated acid monomer, the unsaturated polyether macromonomer and the N-(4-vinylbenzyl)-N,N-dialkylamine is 5.5:1:0.12. The dosages of the oxidizing agent, reducing agent and chain transfer agent in the reduction initiator are 1.0%, 0.5%, and 5.5% of the total molar amount of monomers, respectively.

[0047] Into a 2L flask equipped with a stirrer was added 60% allyl polyethylene glycol (M w =1200, n=26) 480g aqueous solution, 5.44g N-(4-vinylbenzyl)-N,N-diethylamine, 1.80g 30% hydrogen peroxide and 100g water, and pass N 2 In order to remove the oxygen in the solution, then stir and raise the temperature to 30°C. At this temperature, add dropwise a solution consisting of 95.04g of acrylic acid, 6.82g of mercaptoethanol, 2.21g of ferrous sulfate and 220g of water. The dropping time is 2h. After the dripping is completed, keep it for 1 hour, and finally neutralize the reaction liquid with 35% sodium hydroxide solution to a pH of ...

Embodiment 2

[0049] In this embodiment, the molar ratio of the unsaturated acid monomer, the unsaturated polyether macromonomer and the N-(4-vinylbenzyl)-N,N-dialkylamine is 4.5:1:0.09. The amounts of oxidant, reducing agent and chain transfer agent in the reduction initiator are 2.0%, 0.5%, and 2.85% of the total molar amount of monomers, respectively.

[0050] Into a 2L flask equipped with a stirrer was added 60% methallyl polyethylene glycol (M w =1800, n=39) 480g of aqueous solution, 3.12g of N-(4-vinylbenzyl)-N,N-dipropylamine, 2.03g of 30% hydrogen peroxide solution and 100g of water, pass N 2 To remove the oxygen in the solution, then stir and raise the temperature to 43°C. At this temperature, add dropwise a mixture of acrylic acid 46.08g, methacrylic acid 6.88g, mercaptopropionic acid 2.70g, L-ascorbic acid 0.79g and water 190g. The solution is dripped for 3 hours, and after the dripping is completed, the temperature is kept for 1 hour. Finally, the pH of the reaction liquid is neutra...

Embodiment 3

[0052] In this embodiment, the molar ratio of the unsaturated acid monomer, the unsaturated polyether macromonomer and the N-(4-vinylbenzyl)-N,N-dialkylamine is 2.5:1:0.05. The amounts of oxidant, reducing agent and chain transfer agent in the reduction initiator are 3.0%, 1.0%, and 2.5% of the total molar amount of monomers, respectively.

[0053] Into a 2L flask equipped with a stirrer was added 60% prenyl polyethylene glycol (M w =2400, n=53) 480g aqueous solution, 1.81g N-(4-vinylbenzyl)-N,N-dihexylamine, 2.91g ammonium persulfate and 100g water, and pass N 2 In order to remove the oxygen in the solution, the temperature was raised to 50°C under stirring. At this temperature, drops consisting of 15.48g of methacrylic acid and 11.76g of maleic anhydride, 0.98g of thioglycolic acid, 0.75g of L-ascorbic acid and 160g of water were added dropwise. Add the solution for 3.5 hours, keep it for 1 hour after the addition, and finally neutralize the pH of the reaction solution with 35% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com