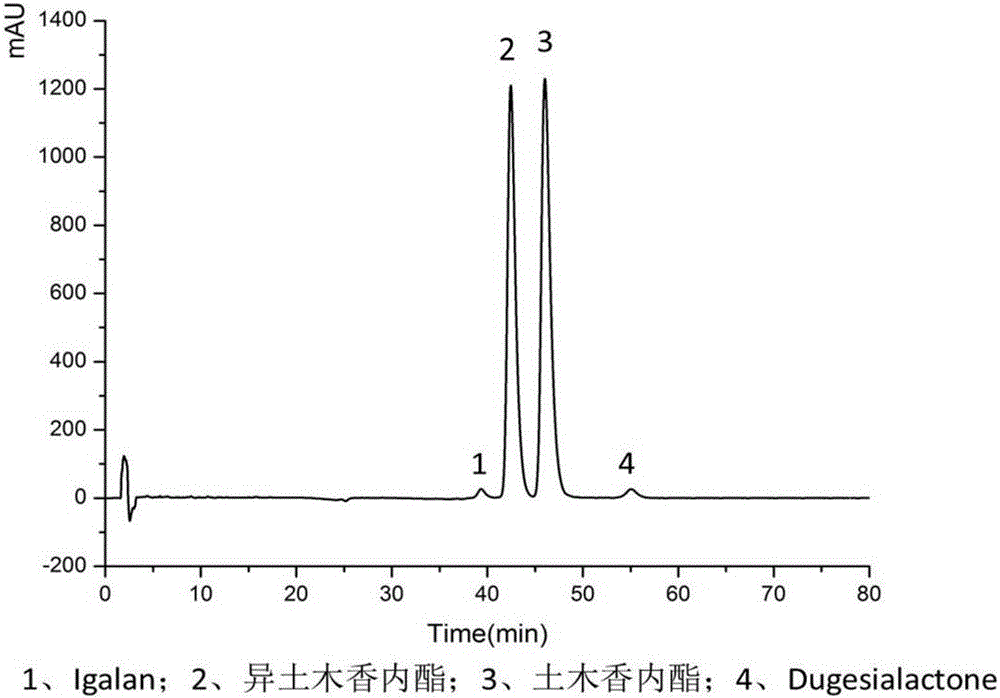

Extracting, separating and preparing method of four sesquiterpene type active components in Tibet inula root

A technology of sesquiterpenoids and active ingredients, which is applied in the field of extraction, separation and preparation of four active ingredients of sesquiterpenoids in Akira sinensis, can solve the problems that have not yet been extracted from active ingredients in Akira sinensis, and achieve easy automatic control , Low production cost, realize the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The method for extracting, separating and preparing four sesquiterpene active components in chrysanthemum, comprising the following steps:

[0034] (1) Pulverize the root of Akiras sinensis to 20 orders to obtain the powder of Akissica sinensis;

[0035] (2) put the Akira sinensis powder obtained in step (1) into the extraction kettle of a subcritical water extraction device, and use deionized water as the extractant for continuous flow extraction, the flow rate of water is controlled at 1mL / min, and the pressure is controlled at 0.5MPa. The temperature is controlled at 120°C, the extraction time is 30 minutes, and the final extract is obtained;

[0036] (3) Put the extract obtained in step (2) into the centrifuge tube of the centrifuge, after centrifuging at a speed of 2000r / min for 5min, remove the centrifuge tube to obtain the supernatant;

[0037] (4) Concentrate and recover the supernatant obtained in step (3) on a rotary evaporator at a temperature of 55° C. and ...

Embodiment 2

[0047] The method for extracting, separating and preparing four sesquiterpene active components in chrysanthemum, comprising the following steps:

[0048] (1) Pulverize the root of Akiras sinensis to 60 orders to obtain the powder of Akissica sinensis;

[0049] (2) Put the Akira sinensis powder obtained in step (1) into the extraction kettle of a subcritical water extraction device, and use distilled water as the extractant for continuous flow extraction, the flow rate of water is controlled at 20mL / min, and the pressure is controlled between 3.0MPa , the temperature is controlled between 250°C, the extraction time is 90min, and the final extract is obtained;

[0050] (3) Put the extract obtained in step (2) into the centrifuge tube of the centrifuge, after centrifuging at a speed of 6000r / min for 15min, remove the centrifuge tube to obtain the supernatant;

[0051] (4) Concentrate and recover the supernatant obtained in step (3) on a rotary evaporator at a temperature of 80°...

Embodiment 3

[0057] The method for extracting, separating and preparing four sesquiterpene active components in chrysanthemum, comprising the following steps:

[0058] (1) Pulverize the root of Akiras sinensis to 40 orders to obtain the powder of Akissica sinensis;

[0059] (2) Put the Akira sinensis powder obtained in step (1) into the extraction kettle of a subcritical water extraction device, and use high-purity water as the extractant for continuous flow extraction, the flow rate of water is controlled at 10mL / min, and the pressure is controlled between 0.4MPa , the temperature is controlled between 185°C, the extraction time is 60min, and the final extract is obtained;

[0060] (3) Put the extract obtained in step (2) into the centrifuge tube of the centrifuge, after centrifuging at a speed of 4000r / min for 10min, remove the centrifuge tube to obtain the supernatant;

[0061] (4) Concentrate and recover the supernatant obtained in step (3) on a rotary evaporator at a temperature of 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com