Neutral transmittance color double-silver low radiation glass and preparation method thereof

A low-emissivity glass and neutral technology, applied in the direction of coating, etc., can solve complex and difficult to see through color problems, and achieve the effect of low shading coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

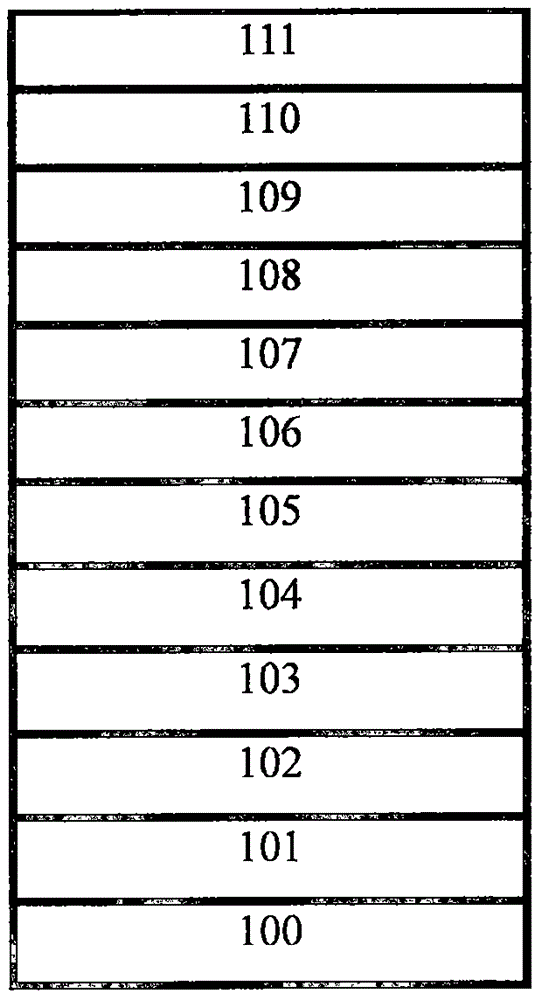

[0026] The thickness of the glass substrate (100) is 4mm, the thickness of the first metal oxide layer 101 is 37.0nm, the thickness of the first oxide layer 102 is 29.0nm, the thickness of the first metal titanium layer 103 is 1.1nm, the thickness of the first metal silver Layer 104 has a thickness of 11.0 nm, the second oxide layer 105 has a thickness of 47.0 nm, the second metal oxide layer 106 has a thickness of 60.0 nm, the second metal silver layer 107 has a thickness of 9.2 nm, and the second metal titanium layer 108 has a thickness of 1.1 nm. , The third oxide layer 109 has a thickness of 30.0 nm, the third metal oxide layer 110 has a thickness of 43.0 nm, and the oxidation protection layer 111 has a thickness of 2.3 nm. The specific operation steps are as follows:

[0027] 1) Clean the glass substrate (100) with a size of 4mm, and set the vacuum degree of the off-line magnetron sputtering equipment at 10 -3 Pa, the line speed is set to 4.0m / min;

[0028] 2) transfer ...

Embodiment 2

[0043] 1) Clean the glass substrate (100) with a size of 6mm, and set the vacuum degree of the off-line magnetron sputtering equipment at 10 -3 Pa, the line speed is set to 3~4m / min;

[0044] 2) transfer the glass substrate into the coating chamber, set the total power of the equipment for coating the first metal oxide layer (101) to 157.0KW, and coat the first layer of oxide layer (101) on the glass substrate with a thickness of 36.0nm;

[0045] 3) The total power of the equipment for plating the first oxide layer (102) is set to 80kW, and the first layer of metal oxide (102) is plated on the glass substrate with a thickness of 25.0nm;

[0046] 4) The total power of the equipment for plating the first metal titanium layer (103) is set to 7.2kW, and the first layer of metal titanium (103) is plated on the glass substrate with a thickness of 0.9nm;

[0047] 5) Set the total power of the equipment for plating the first layer of metallic silver (104) to 9.0kW, and plate the firs...

Embodiment 3

[0059] 1) Clean the glass substrate (100) with a size of 6mm, and set the vacuum degree of the off-line magnetron sputtering equipment at 10 -3 Pa, the line speed is set to 3~4m / min;

[0060] 2) transfer the glass substrate into the coating chamber, set the total power of the equipment for coating the first metal oxide layer (101) to 165.0KW, and coat the first layer of oxide layer (101) 42.0nm on the glass substrate;

[0061] 3) The total power of the equipment for plating the first oxide layer (102) is set to 90kW, and the first layer of metal oxide (102) is plated on the glass substrate with a thickness of 30.0nm;

[0062] 4) The total power of the equipment for plating the first metal titanium layer (103) is set to 8.2kW, and the first layer of metal titanium (103) is plated on the glass substrate with a thickness of 1.5nm;

[0063] 5) Set the total power of the equipment for plating the first layer of metallic silver (104) to 9.5kW, and plate the first layer of metallic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com