Advanced treatment and recycling method of silk reeling production wastewater

A production wastewater and advanced treatment technology, applied in energy wastewater treatment, biological water/sewage treatment, reflux water treatment, etc., can solve the problems of unsatisfactory total phosphorus index results, high wastewater concentration, poor treatment effect, etc., and achieve long-term operation Stable and reliable, good denitrification effect, good water quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the method for advanced treatment and recycling of the silk reeling production wastewater of the present invention will be further described with reference to the accompanying drawings and embodiments.

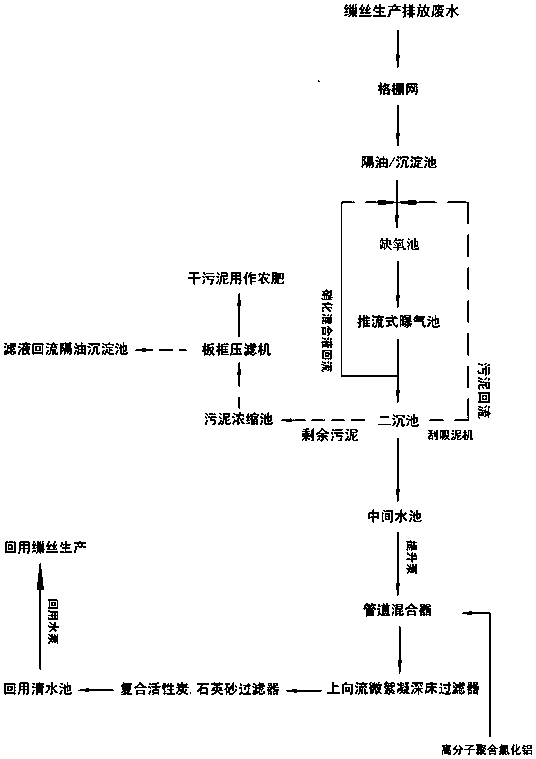

[0028] Such as figure 1 As shown, a method for advanced treatment and reuse of silk reeling wastewater includes the following steps:

[0029] A. The silk reeling production wastewater is firstly removed by the first-level pretreatment unit composed of grid mesh and oil-separation sedimentation tank to remove floating matter, grease and suspended matter; the surface hydraulic load of the oil-separation sedimentation tank is 1.5-2.5m 3 / m 2 ·H, precipitation time 1.5-2.0h;

[0030] B. After removing floating matter, grease and suspended matter, the reeling wastewater from the oil separation sedimentation tank enters the secondary biological treatment unit composed of anoxic tank, push-flow aeration tank, and secondary sedimentation tank to remove most of it Organic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com