Integrated multifunctional ceramic packaging tube shell

A multi-functional ceramic package shell technology, which is applied in the direction of measuring devices, electric solid state devices, semiconductor devices, etc., can solve the problems of high complexity of traditional packaging process, not conforming to the development trend of the industry, and large volume of packaged devices. Good for volume, excellent mechanical shock resistance, and large metal area resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

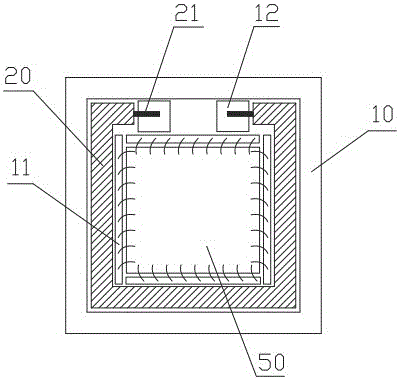

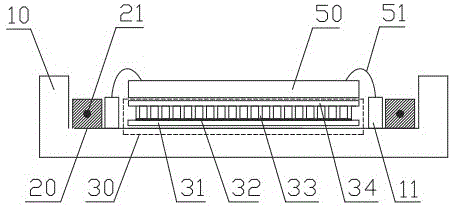

[0032] Example 1: see image 3 and Figure 4 , an integrated multi-functional ceramic packaging package, comprising a ceramic package package 10, a getter module 20, a temperature control module 30 and a temperature measurement module 40, the getter module 20, the temperature measurement module 40 and a temperature control module The module 30 is integrated with the ceramic packaging package 10 .

[0033] Specifically, the getter module 20 includes a metal area 21 and a getter material layer 22. The metal area 21 is planar, and the metal material can be heated by resistance such as tungsten or molybdenum. By including but not limited to metal paste Material printing, electroplating or chemical deposition methods and other processing methods are directly grown on the inner surface of the ceramic package shell, preferably using a metal paste printing process; the getter material layer 22 can be obtained by including but not limited to sputtering, coating The metal area 21 is g...

Embodiment 2

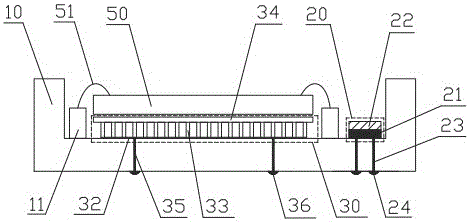

[0041] Example 2: see Figure 5 and Figure 6 , the other parts are the same as in Embodiment 1, the difference is that: the metal region 21 is in the shape of a convex-concave wall, and the getter material layer 22 is grown on the metal region in the shape of a convex-concave wall. Compared with the planar metal area, the metal area in the shape of a convex-concave wall can increase the contact area of the getter material layer, enhance the air-absorbing effect, and prolong the service life of the packaged device.

[0042] In the present invention, the integrated design of the getter module, the temperature control module, the temperature measurement module and the ceramic packaging shell can realize the functions of air suction, temperature control and temperature measurement of the package shell. Under this condition, the subsequent Packaging only needs to paste the MEMS device or chip 50 on the ceramic sheet of the TEC temperature control element, and connect it to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com