Mold Apparatus And Resin Molding Method

A technology of resin molding and moulding, which is applied to household appliances, other household appliances, household components, etc., can solve problems such as the movement of the rotating core, and achieve the effect of preventing the occurrence of the core wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

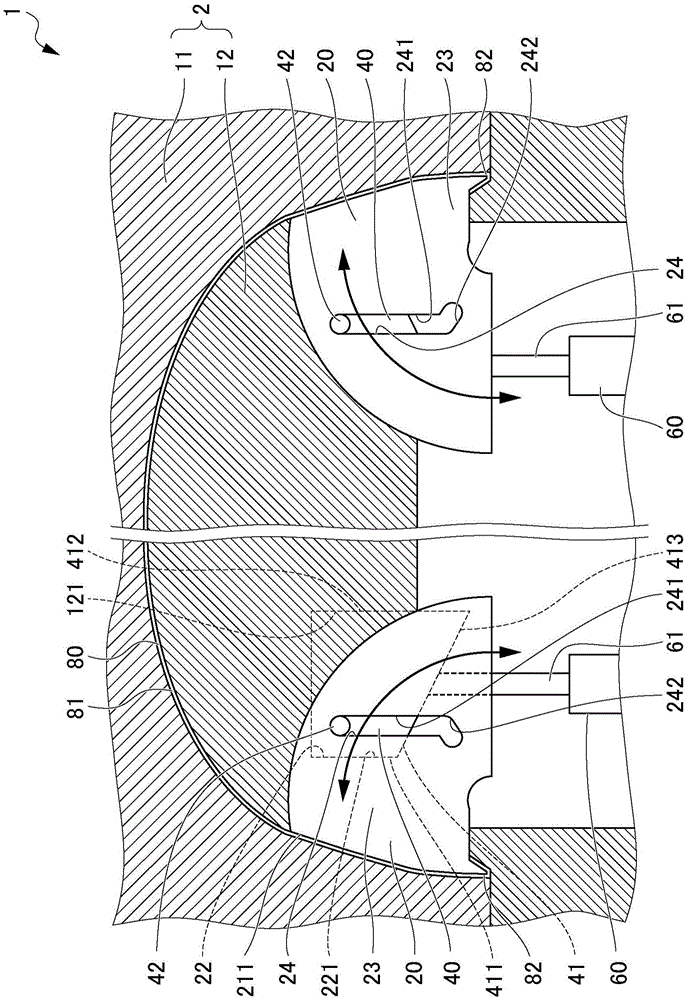

[0042] Below, while referring to the attached Figure 1 A preferred embodiment of the mold device of the present invention will be described. figure 1 It is a figure which schematically shows the mold apparatus 1 which concerns on one Embodiment of this invention.

[0043] As one embodiment of the present invention, a mold device 1 for resin-molding a bumper of an automobile as a molding 80 will be described. Such as figure 1 As shown, the molding 80 is comprised of a body portion 81 and a barb portion 82 formed at the end of the body portion 81 . The barb portion 82 of the molding 80 constitutes a portion for mounting the bumper portion to a vehicle body made of metal. The barb portion 82 of the present embodiment has a V-shaped cross-sectional shape.

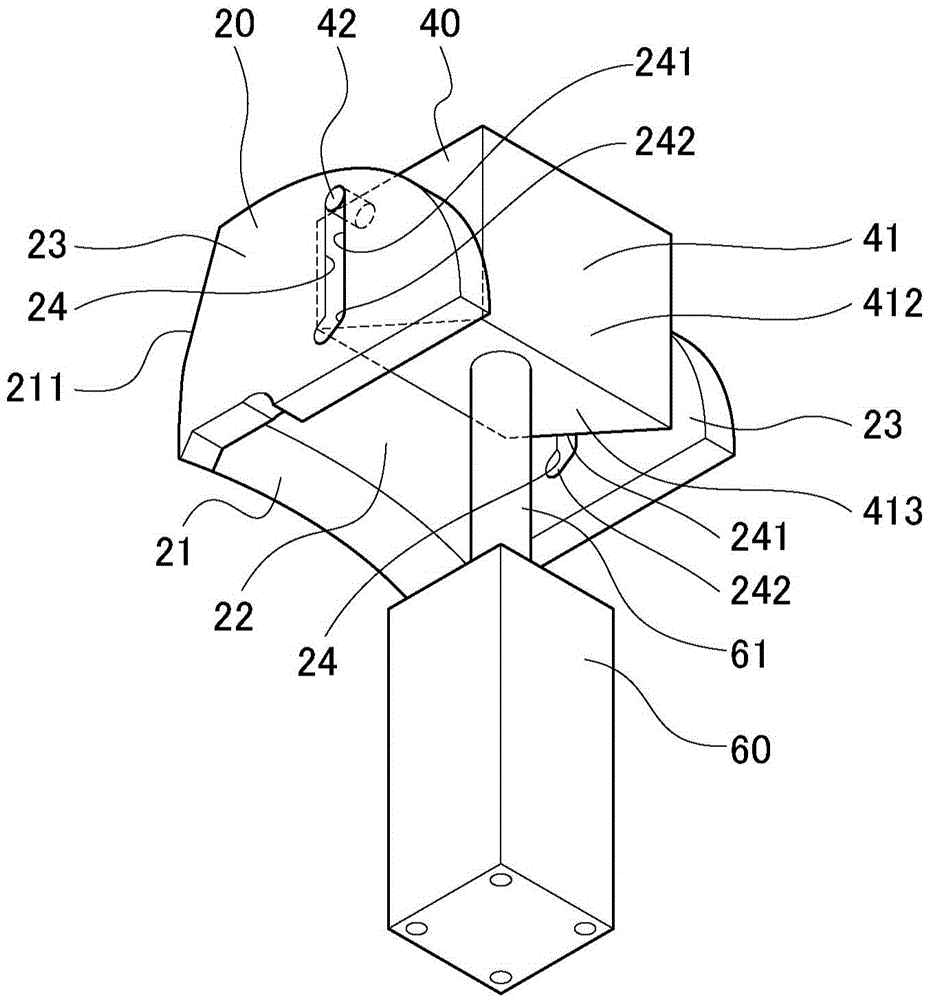

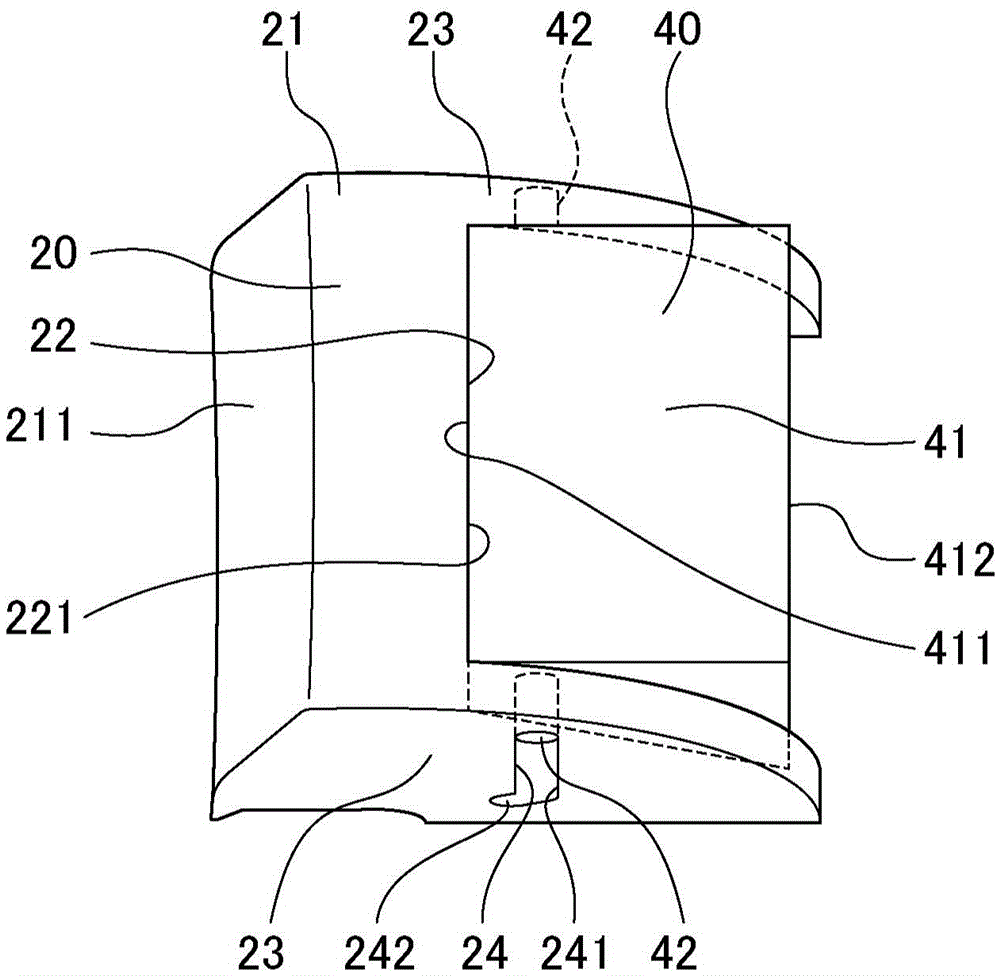

[0044] Each structure of the mold device 1 for molding the molded product 80 will be described. The mold device 1 of the present embodiment includes a mold body 2 , a rotary core 20 , a restricting core 40 , and a drive c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com