Brazing type diamond truing pens and processing method

A technology of diamond pens and processing methods, which is applied in the fields of polishing, machinery and grinding, and can solve the problems of adverse effects of trimming work, affecting the use effect, and pen strips are easy to fall off, and achieves low cost, good cooling, and neatly arranged pen strips. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

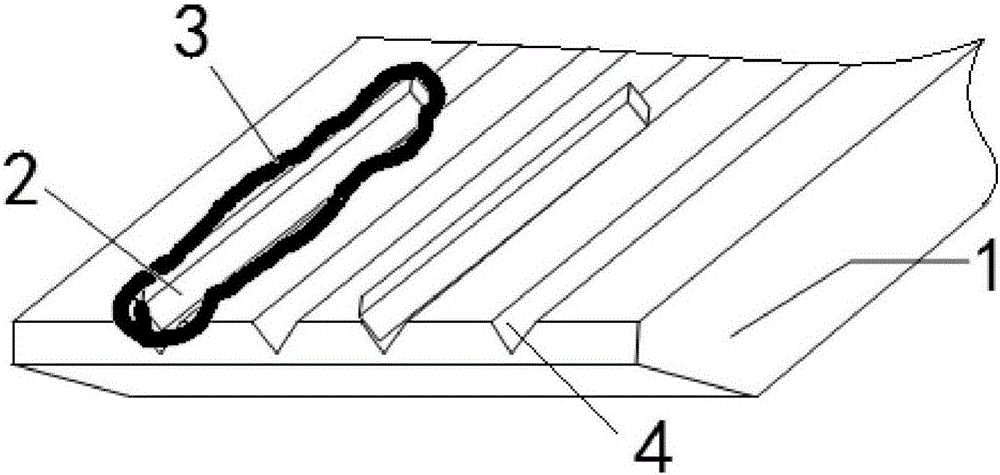

[0026] Embodiment 1: as figure 1 , figure 2 As shown, a brazing type diamond pen bar trimming pen, the metal substrate surface 1 has a groove 4, the solder 3 wraps the diamond pen bar 2, and the solder 3 connects the groove 4.

[0027] The grooves 4 are V-shaped grooves, rectangular grooves or arc grooves, the diamond pen strips 2 are strip-shaped, the grooves 4 are arranged side by side on the surface 1 of the metal base, and there are intervals between the grooves 4.

[0028] The diamond pen strip 2 is all lying in the groove 4, or in other words: the thickness of the diamond pen strip 2 is less than or equal to the depth of the groove 4,

[0029] Further, the thickness of the diamond pen strip 2 is greater than the depth of the groove 4.

[0030] Further, after the solder 3 wraps the diamond pen strip 2, it all lies in the groove 4.

[0031] Further, the solder 3 wraps the diamond pen strip 2 and is higher than the slot 4 .

[0032] Further, each of the groove 4 and th...

Embodiment 2

[0034] Embodiment 2: A kind of brazing type diamond pen trimming pen, the metal substrate surface 1 has solder 3 wrapped diamond pen strips 2, the diamond pen strips 2 are arranged side by side on the metal substrate surface 1, and there are intervals between the diamond pen strips 2. The groove 4 is a V-shaped groove, a rectangular groove or an arc groove, and the diamond pen strip 2 is strip-shaped.

Embodiment 3

[0035] Embodiment 3: A brazing type diamond pen strip trimming pen, the metal substrate surface 1 has a groove 4, the solder 3 wraps the diamond pen strip 2, and the solder 3 connects the groove 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com