Disc cam driving type cylindrical workpiece centering and clamping fixture

A technology of cylindrical workpieces and disc cams, applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of difficult disassembly, chuck wear, heavy weight, etc., and achieve simple and compact structure, long service life, and automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

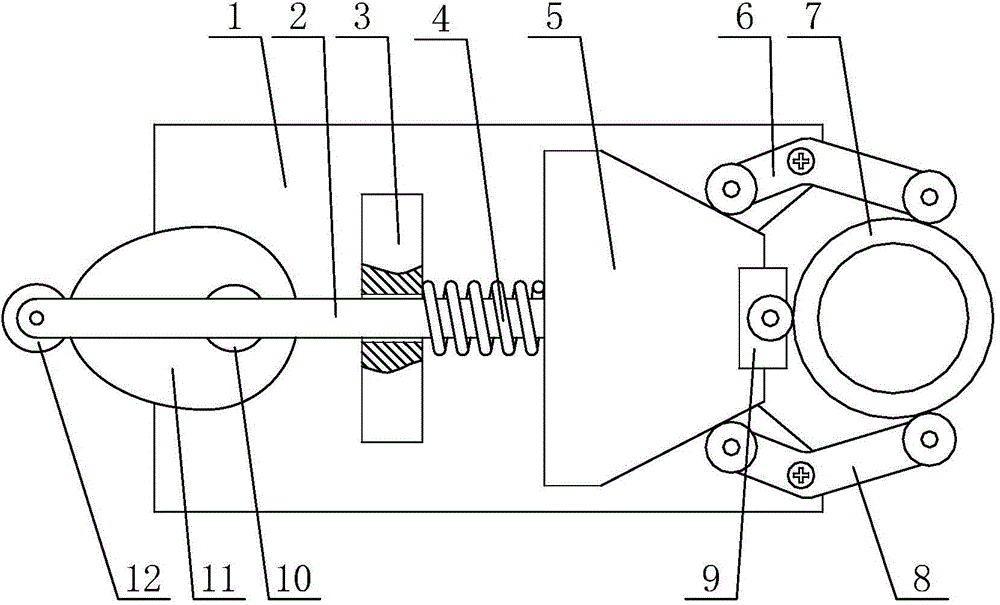

[0020] like figure 1 A disc-shaped cam-driven centering clamping fixture for a cylindrical workpiece as shown includes a bottom plate 1 with a V-shaped groove at one end, and an inclined-plane push head 5 for tightening a ring-shaped workpiece 7, and the inclined-plane push head 5 for pushing against the inclined-plane. The head 5 cooperates with the bending arm one 6 and the bending arm two 8 for clamping the cylindrical workpiece 7 from the outside, and cooperates with the drive spring 4 and the disc cam 11 for driving the inclined-plane push head 5 to move back and forth; The middle part of the bottom plate 1 is slidably installed with the slide bar 2 through the slide bar support 3, one end of the slide bar 2 is rotatably mounted with a roller 12, and the other end of the slide bar 2 is fixedly mounted with the front end with a top block 9. Inclined push head 5, a drive spring 4 is set on the slide rod 2 between the slope push head 5 and the slide bar support 3, and one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com