Radial adjusting mechanism of Y-shaped rolling mill

A technology for adjusting mechanism and rolling mill, applied in the direction of metal rolling mill stand, metal rolling stand, metal rolling, etc., can solve the problem of high manufacturing cost and maintenance cost, large and complex structure of C-shaped stand, and can not adapt to special-shaped products Rolling and other problems, to achieve the effect of online rapid automatic accurate adjustment, saving rolling line space, fast and accurate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

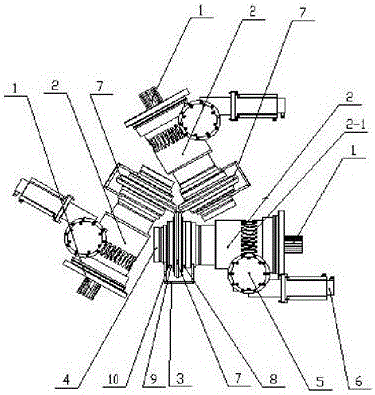

[0032] Such as figure 1 As shown, the technical solution adopted by the present invention includes three main shafts 1, and a main eccentric sleeve 2 and a secondary eccentric sleeve 4 are installed on each main shaft 1, wherein the main eccentric sleeve 2 is an eccentric sleeve with a worm gear, and the eccentric sleeve with a worm gear The structure of the main eccentric sleeve 2 is that an integrated worm wheel 2-1 is processed on the body of the main eccentric sleeve 2 to form a main eccentric sleeve 2 with a worm gear integrated with the body of the worm wheel 2-1 and the main eccentric sleeve 2, so that Improve the strength of the eccentric sleeve, eliminate the assembly gap between the worm gear and the eccentric sleeve, and avoid assembly accuracy errors; the main eccentric sleeve 2 with the worm wheel and the secondary eccentric sleeve 4 are connected through the eccentric sleeve connector 3, and each belt A worm gear mechanism 5 is installed on the main eccentric sle...

specific Embodiment approach 2

[0035] Such as figure 1 , image 3 , Figure 4 with Figure 5 As shown, it is the same as the primary transmission described in Embodiment 1, the difference is that a secondary worm gear 15 is installed on the first worm 13 in the primary transmission, the secondary worm gear 15 is connected to the second worm 16, and the secondary worm gear 15 Installed in the second support sleeve 14-2 through the bearing, the second support sleeve 14-2 is connected with the rack of the rolling mill, when the second worm 16 rotates, it drives the second worm wheel 15 to rotate, and the second worm wheel drives the first The worm 13 rotates, the first worm 13 drives the main eccentric sleeve 2 with worm gear to rotate, and drives the secondary eccentric sleeve 4 to rotate together through the eccentric sleeve connector 3, so that the main shaft 1 rises or falls, and the roll 7 is driven to rise or fall, and the roll diameter is completed. To the precise adjustment of the position, the serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com