Bright pipe body processing craft

A processing technology and tube body technology, applied in the field of bright tube body processing technology, can solve the problems affecting the use of luggage and furniture, affecting the sliding smoothness, and the strip steel is prone to rust, etc., and achieves good heat treatment uniformity and stable mechanical properties. , the effect of high finished product efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

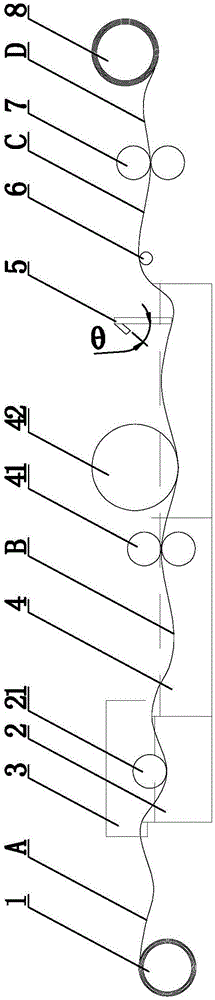

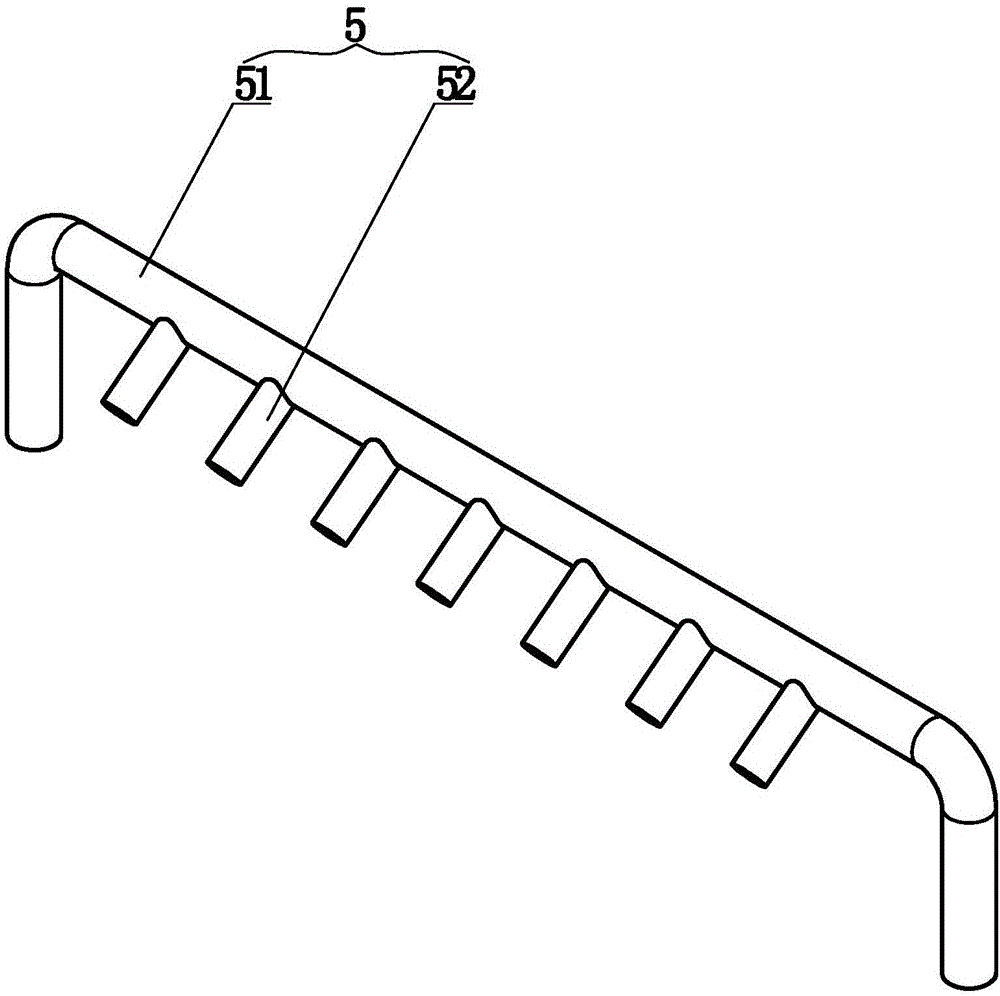

[0027] The present embodiment bright tube body processing technology, combines figure 1 , including feeding roll 1, pickling tank 2, cleaning tank 4 and rolling mill 7 installed in sequence; a hot box 3 is arranged above the pickling tank 2, and a guide roll with the bottom immersed in the pickling solution is arranged in it -21, the hot box 3 forms a closed structure above the pickling tank 2, and keeps the temperature in the pickling tank 2 at 55-60°C, and the humid and hot atmosphere of acidification is conducive to the acidification; (volume concentration) of hydrochloric acid, the wool material A supplied by the feed roller 1 stays in the pickling tank 2 for 3-4 minutes to obtain the acidified material B, which is sent into the cleaning tank 4, and the cleaning solution in the cleaning tank 4 Under the action of the acidification material B, the acid on the surface of the acidizing material B can be removed to form a crude product, wherein a guide roller 41 formed by a pa...

Embodiment 2

[0032] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that two rolling mills are arranged between the cleaning mechanism 5 and the rolling mill 7, and the cleaned rough products are rolled to 1.8mm and 0.5mm in turn for pre-extrusion , and then sent to the joint rolling mill 7 for thinning to a set thickness.

[0033] The crude product is first pre-extruded in one or more rolling mills, and then sent to the joint rolling mill for final thinning. The pipes formed by this method have uniform quality and stable mechanical properties.

Embodiment 3

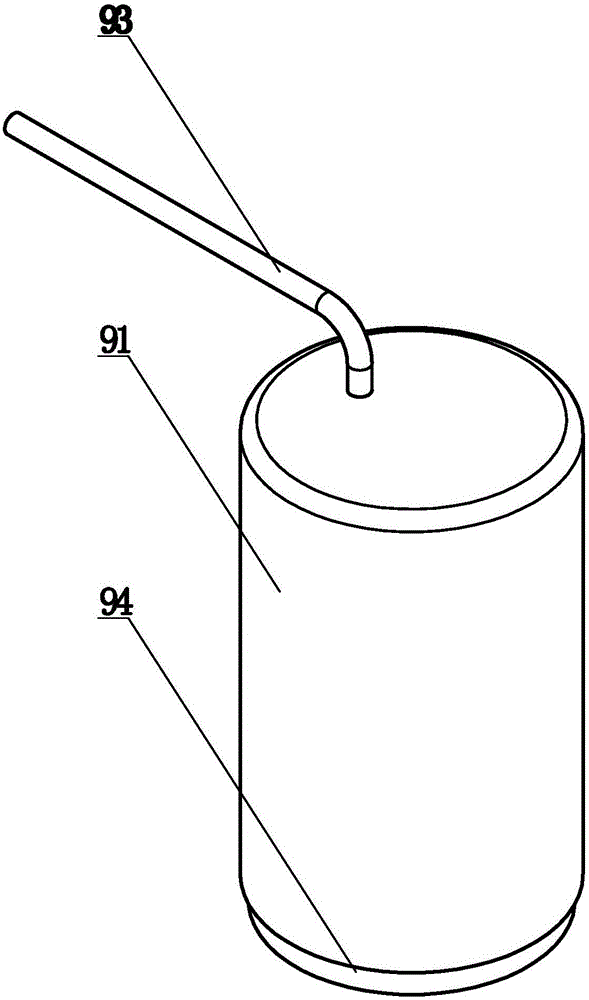

[0035] The setting and working principle of this embodiment are the same as those of Embodiment 1, the difference is that a heat treatment furnace 9 is arranged behind the rolling mill 7, and the initial product D is sent into the heat treatment furnace 9, and is treated at 600° C. for 24 hours under the protection of liquid nitrogen. ,cool down. Specifically in this embodiment, combined with image 3 and Figure 4 , the heat treatment furnace 9 includes an outer cover 91, an inner cover 92, a liquid nitrogen channel 93 and a base 94, the inner cover 92 is fixed on the base 94, the outer cover 91 is set on the inner cover 92, and the top of the outer cover 92 communicates with the liquid nitrogen channel 93, and the liquid nitrogen Burn NH through a calciner 3 , and feed into between the inner cover 92 and the outer cover 91 through the liquid nitrogen channel 93, and the inner wall of the outer cover 91 is provided with a heating wire 95, and the heating wire 95 is energize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com