Potassium and manganese composite oxide and preparing method and application thereof to diesel vehicle tail gas purification

A technology for composite oxides and diesel vehicles, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as easy loss of K, weakened activity, and reduced lifespan , achieve the effects of cheap raw materials, lower light-off temperature and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Accurately weigh 1.3521gMnSO 4 ·H 2 O, 1.8526g(NH 4 ) 2 S 2 O 8 ,1.9821g(NH 4 ) 2 SO 4 , Put in a 100mL beaker, add 40mL deionized water, stir and dissolve for 20min to obtain a mixed solution; then accurately weigh the KNO 3 3.2353g, added to the mixed solution under vigorous stirring, and stirred and dissolved for 30 minutes to obtain a clear mixed solution; transfer the mixed solution to a polytetrafluoroethylene liner, seal, and move it into a stainless steel reactor. The reaction kettle was hydrothermally aged at 120°C in an oven for 20 hours, cooled naturally to room temperature, and the kettle was opened. The reaction product was washed with deionization and suction filtered. The product was dried at 120°C for 12 hours to obtain potassium manganese composite oxide.

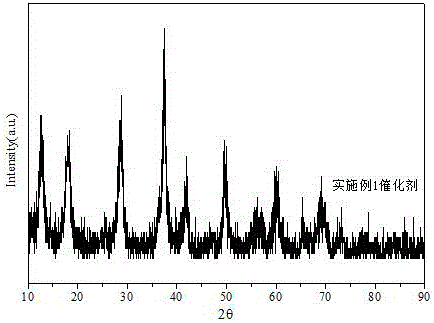

[0033] figure 1 Is the XRD spectrum of the obtained product. It can be seen from the figure that the catalyst meets the K 2-x Mn 8 O 16 This type of composite oxide has a tunnel structure.

Embodiment 2

[0035] Accurately weigh 1.3521gMnSO 4 ·H 2 O, 1.8526g(NH 4 ) 2 S 2 O 8 ,1.9821g(NH 4 ) 2 SO 4 , Put in a 100mL beaker, add 20mL deionized water, stir and dissolve for 20min to obtain a mixed solution; then accurately weigh the KNO 3 0.4044g, added to the mixed solution under vigorous stirring, and stirred and dissolved for 30 minutes to obtain a clear mixed solution; transfer the mixed solution to a polytetrafluoroethylene lining, seal, and move it into a stainless steel reactor. The reaction kettle was hydrothermally aged at 120°C for 20 hours in an oven, naturally cooled to room temperature, and the kettle was opened. The reaction product was washed with deionization, suction filtered, and dried at 120°C for 12 hours to obtain potassium manganese composite oxide. The molecular formula of the resulting product is K 2-x Mn 8 O 16 , Has a tunnel structure. The XRD pattern of the resulting product and figure 1 similar.

Embodiment 3

[0037] Accurately weigh 1.3521gMnSO 4 ·H 2 O, 1.8526g(NH 4 ) 2 S 2 O 8 ,1.9821g(NH 4 ) 2 SO 4 , Put in a 100mL beaker, add 40mL deionized water, stir and dissolve for 10min to obtain a mixed solution; then accurately weigh the KNO 3 1.6176g, added to the mixed solution under vigorous stirring, and stirred and dissolved for 30 minutes to obtain a clear mixed solution; transfer the mixed solution to a polytetrafluoroethylene lining, seal, and move it into a stainless steel reactor. The reaction kettle was hydrothermally aged at 200°C for 12 hours in an oven, cooled to room temperature naturally, and the kettle was opened. The reaction product was washed with deionization, suction filtered, and dried at 120°C for 10 hours to obtain potassium manganese composite oxide. The molecular formula of the resulting product is K 2-x Mn 8 O 16 , Has a tunnel structure. The XRD pattern of the resulting product and figure 1 similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com